Setting up a carburetor control mechanism is crucial for achieving optimal engine performance and reliability. This process involves configuring a device that regulates the air-fuel mixture entering the engine, which is essential for smooth operation, especially in varying conditions. Proper adjustment of this component ensures that your engine runs efficiently and effectively across different driving scenarios.

The setup process generally includes attaching the control unit to the carburetor and making precise adjustments to synchronize its operation with the engine’s needs. This task requires attention to detail and an understanding of how changes in the control device affect engine performance. By following the correct procedures, you can enhance the responsiveness and fuel efficiency of your vehicle.

Ensure to carefully follow the outlined steps for installation and adjustment to achieve the best results. Proper configuration will not only improve engine functionality but also contribute to overall driving satisfaction and vehicle longevity.

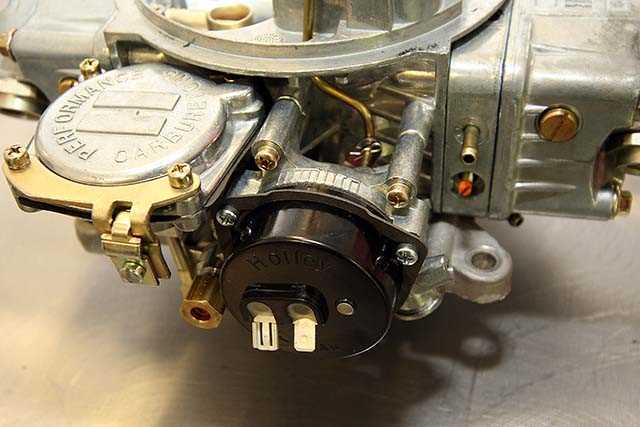

Holley Manual Choke Setup Guide

Setting up a manual control for your vehicle’s air-fuel system can significantly enhance performance and ease of use. This process involves integrating a user-operated mechanism that allows precise adjustment of the fuel mixture. Following these steps will help ensure a successful configuration and optimal functionality.

- Start by locating the existing air-fuel system component that will be replaced or modified. Consult your vehicle’s specifications to understand the correct placement and connection points.

- Prepare the necessary tools and components, including the control lever, linkage, and any required fasteners. Ensure all parts are compatible with your system.

- Carefully remove the existing setup, making sure not to damage any surrounding parts. Clean the area to ensure a smooth installation of the new control mechanism.

- Install the new control system according to the provided guidelines. Attach the linkage and ensure it operates smoothly. Verify that all connections are secure and properly aligned.

- Test the new setup by adjusting the control and monitoring the vehicle’s performance. Make any necessary adjustments to achieve the desired results.

Following these steps will help you successfully integrate a manual adjustment system into your vehicle’s air-fuel mechanism, enhancing its overall performance and reliability.

Understanding Manual Choke Functionality

The mechanism in question is an essential component in regulating the flow of air during the initial operation of an engine. By adjusting this mechanism, it ensures the optimal air-to-fuel ratio, facilitating a smoother start, especially in cold conditions. The system works by temporarily restricting airflow to enrich the fuel mixture, allowing the engine to reach operating temperature more efficiently.

Key Aspects of this system include the ability to manually control the airflow, which provides flexibility depending on the engine’s needs. Proper understanding of its operation can lead to improved performance and engine longevity, making it crucial for those looking to optimize their vehicle’s start-up process.

Necessary Tools for Choke Installation

Before starting the process, it is essential to gather all the required tools to ensure a smooth and efficient setup. Having everything ready will save time and help avoid interruptions during the procedure.

- Screwdrivers: A set of flathead and Phillips screwdrivers will be needed for securing various components.

- Wrenches: Both adjustable and fixed-size wrenches are useful for tightening bolts and nuts.

- Socket Set: A comprehensive socket set will be necessary to handle bolts of different sizes, ensuring a proper fit.

- Pliers: Needle-nose pliers can help in gripping and positioning small parts or wires.

- Wire Strippers: These are required for preparing wires to connect to electrical components.

- Measuring Tape: Accurate measurements are crucial for positioning elements correctly.

Ensuring that all these tools are on hand before beginning will make the task more straightforward and help prevent delays.

Preparing the Carburetor for Installation

Before securing the component, it’s crucial to ensure the mechanism is adequately prepared. This involves a few preliminary steps that will help achieve optimal performance. Proper attention to these details can prevent issues during operation and ensure a smooth setup process.

Initial Checks and Cleaning

Begin by thoroughly inspecting the unit for any debris or residues that might have accumulated. Use a suitable cleaner to remove any contaminants that could affect functionality. Make sure all passages and surfaces are clear, paying particular attention to the intricate parts.

Adjusting the Linkages

Next, verify that all linkages are properly aligned and move freely. Adjust the settings to match the specific needs of your engine setup, ensuring smooth operation. Proper adjustment at this stage is vital for achieving the desired responsiveness.

| Step | Description |

|---|---|

| Inspection | Check for debris, wear, or damage. |

| Cleaning | Remove any contaminants using a suitable cleaner. |

| Linkage Adjustment | Ensure li

Step-by-Step Choke Installation ProcessIn this section, we’ll explore the detailed procedure for setting up a vital engine component that enhances performance during cold starts. Following these guidelines ensures that the component operates efficiently, providing the necessary adjustments to fuel flow based on engine temperature. Preparation and ToolsBefore beginning the setup, gather all required tools and materials. Ensure the engine is cool and the vehicle is on a level surface. Disconnect the battery to prevent any accidental electrical issues. Having the right tools ready will make the process smoother and more efficient. Component PositioningNext, carefully position the component on the engine according to the specific configuration of your vehicle. Ensure that all connections are aligned properly before securing them. Tighten bolts and screws securely but avoid over-tightening to prevent damage. Once the component is securely in place, reconnect the battery and test the system by starting the engine. Make sure it operates smoothly and adjusts as expected during warm-up. If any issues arise, refer back to the setup steps to verify that everything is correctly installed. Testing and Adjusting the Manual ChokeEnsuring the smooth operation of your engine’s fuel delivery system is essential for optimal performance. This section focuses on verifying and fine-tuning the mechanism that regulates air and fuel mixture during engine startup. To begin, start the engine and observe the behavior of the system as it warms up. If the engine struggles to maintain a steady idle, or if there are signs of stalling or rough operation, adjustments may be necessary. Using a screwdriver, make small adjustments to the linkage until the engine runs smoothly without hesitation. After making adjustments, test the engine again by starting it when cold and noting any changes in its behavior. Continue fine-tuning as needed to achieve a consistent and smooth start, ensuring the mechanism properly responds to temperature changes. This process is crucial for maintaining efficient and reliable engine performance. Troubleshooting Common Installation IssuesWhen setting up a new system, certain challenges might arise that can hinder proper operation. These problems often stem from minor oversights or misalignments during the process. Identifying and addressing these issues early can ensure smoother functionality and prevent long-term complications.

By carefully examining these areas, most common issues can be resolved, leading to a more reliable and efficient setup. |