Understanding the operation and maintenance of marine lifting devices is crucial for ensuring their optimal performance and longevity. This section provides comprehensive insights into the essential practices and safety protocols associated with these vital pieces of equipment.

Effective handling of such machinery involves mastering a series of procedural steps and adhering to established safety guidelines. This guide aims to equip users with the knowledge required to operate these tools efficiently while minimizing the risk of accidents and equipment failure.

Through detailed explanations and practical advice, this resource serves as a valuable tool for both new and experienced operators. By familiarizing yourself with the outlined procedures, you will enhance your ability to manage these systems effectively and uphold the highest standards of safety and functionality.

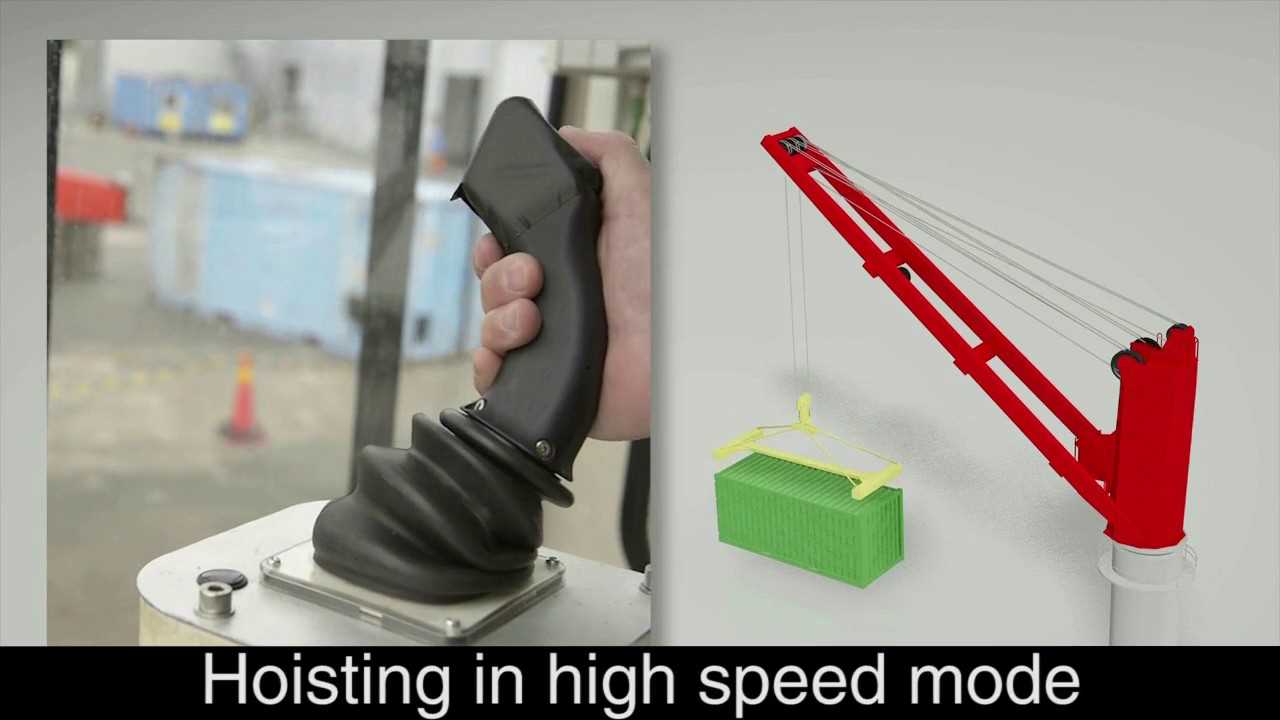

Overview of Macgregor Deck Crane

This section provides a comprehensive overview of the lifting apparatus designed for marine and industrial applications. The equipment discussed is integral for handling heavy loads on vessels and at various operational sites. Its design facilitates efficient and safe transfer of cargo, enhancing productivity and operational efficiency.

The machinery is characterized by its robust construction, which ensures durability under harsh conditions. It is engineered to handle a wide range of lifting tasks, from standard to specialized operations. With advanced features and technology, it offers reliable performance and ease of use.

| Feature | Description |

|---|---|

| Construction Material | Durable and corrosion-resistant materials suitable for marine environments. |

| Load Capacity | Capable of lifting substantial weights with precision and safety. |

| Operational Range | Versatile in various lifting scenarios, from standard operations to complex tasks. |

| Technology | Incorporates advanced systems for enhanced control and performance. |

| Safety Features | Equipped with safety mechanisms to prevent accidents and ensure secure handling. |

Understanding the key aspects of this lifting device allows users to appreciate its value in enhancing operational capabilities and safety in lifting operations. This overview serves as a foundation for deeper insights into the equipment’s specific functionalities and applications.

Key Features and Specifications

In this section, we will explore the main characteristics and technical aspects that define the equipment’s performance and efficiency. Understanding these attributes is essential for effective operation and maintenance.

Core Capabilities

The machinery boasts robust load-handling capabilities, offering seamless integration with various operational tasks. It is designed to handle a wide range of materials, ensuring adaptability to different industrial environments. The equipment’s flexibility and precision allow for both rapid and accurate performance, optimizing workflow efficiency.

Technical Specifications

The system is equipped with advanced hydraulic mechanisms for enhanced control and stability during operations. Its high-tensile structure ensures durability under extreme conditions, providing a long service life. The power capacity and lifting range are tailored to meet diverse operational needs, while the integration of safety features guarantees secure and reliable use in demanding situations.

Installation Guidelines and Requirements

Proper installation of lifting equipment is essential for ensuring safe and efficient operation. This section outlines the general procedures and prerequisites that need to be followed to achieve a reliable setup. It is important to adhere to these guidelines to avoid potential hazards and ensure optimal performance of the machinery.

Site Preparation

Before commencing the installation process, a thorough assessment of the worksite is required. Ensure that the foundation is level and can support the weight of the structure. Clear the area of any obstructions that could interfere with the setup. Additionally, verify that the installation site complies with all relevant safety regulations and standards to prevent delays or complications during assembly.

Structural and Mechanical Requirements

The installation must be conducted by certified personnel with expertise in handling heavy machinery. All structural components should be inspected for integrity and precision before assembly. Make sure that all mechanical systems, including lifting and control mechanisms, are properly aligned and free from defects. It is also crucial to follow the manufacturer’s specifications for bolting and welding to ensure structural stability.

Once the equipment is installed, perform a series of load tests to verify that it operates within the specified safety limits. These tests should include checks for balance, movement range, and load capacity to confirm that the system is functioning as designed.

Operation Procedures and Best Practices

Understanding the correct processes for managing heavy machinery is essential for maintaining a safe and efficient workflow. Following established protocols ensures smooth operations and minimizes the risk of errors or accidents during equipment use. This section will outline key recommendations and proven methods for handling such tasks effectively.

Pre-Operational Checks

Before initiating any task, it is crucial to perform thorough inspections of all components. Confirm that all parts are in proper working order, and address any signs of wear or damage. Routine maintenance and attention to detail during these checks can prevent future malfunctions and extend the equipment’s lifespan.

Safe Handling Techniques

During operation, always prioritize the safety of both the operator and those nearby. Ensure that the equipment is properly balanced and never exceed the recommended load capacity. Employing safe handling techniques can drastically reduce the likelihood of accidents and improve overall efficiency. Operators should also remain aware of their surroundings, avoiding sudden movements or unexpected changes in operation.

By following these best practices and adhering to proper guidelines, tasks can be completed safely and efficiently, while maintaining optimal performance standards.

Maintenance and Safety Recommendations

Regular upkeep and adherence to safety protocols are essential to ensure the long-term functionality and reliability of any equipment. Following proper guidelines can prevent accidents, reduce wear, and enhance performance. Below are key points to keep in mind for ensuring operational safety and maintaining equipment in optimal condition.

Regular Maintenance

- Inspect all mechanical parts for signs of wear or damage.

- Lubricate moving components as per the manufacturer’s guidelines to avoid friction and ensure smooth operation.

- Replace worn or damaged parts promptly to prevent system failures.

- Ensure all safety mechanisms are fully operational before each use.

Safety Precautions

- Always perform a visual inspection before operating any machinery.

- Ensure that all operators are trained and aware of the safety protocols.

- Use appropriate personal protective equipment (PPE) at all times when operating or maintaining machinery.

- Regularly check the control systems for responsiveness and recalibrate them as needed.

- In case of any irregularities, stop the operation immediately and consult a professional technician.

Common Troubleshooting Techniques

In this section, we will explore general strategies for resolving issues that may arise during the operation of heavy machinery. By identifying potential faults early, it is possible to minimize downtime and maintain optimal performance.

Identifying Common Symptoms

Understanding the symptoms of malfunctions is a crucial first step in troubleshooting. These symptoms often include unusual noises, reduced functionality, or unexpected shutdowns. Keeping track of these signs can help pinpoint the cause of the issue and guide the repair process.

Effective Diagnostic Methods

To ensure accurate diagnosis, it’s important to follow a structured approach. This involves checking electrical systems, hydraulic components, and mechanical parts. Regular inspection of these elements helps in identifying wear or damage that could lead to larger problems if left unattended.

| Symptom | Possible Cause | Suggested Action |

|---|---|---|

| Unusual noise | Worn bearings | Inspect and replace bearings |

| Slow operation | Hydraulic fluid issues | Check and refill fluid levels |

| Unexpected shutdown | Electrical fault | Examine wiring and connections |

Contact Information for Support Services

If you require assistance with any technical or operational inquiries, our dedicated support team is available to help. We offer multiple channels to ensure your questions are addressed efficiently and promptly.

Please find the relevant contact details below:

- Phone Support: Our customer service representatives are available by phone during business hours. You can reach us at the following number: +1 (800) 123-4567.

- Email Assistance: For non-urgent matters, feel free to send us an email at [email protected]. Our team typically responds within 24 hours.

- Live Chat: Available through our website, live chat is ideal for quick responses to general queries. Our chat support operates 24/7.

- Service Center Locator: If you need in-person support, you can find the nearest service center by visiting our online locator tool.

We recommend providing as much detail as possible when reaching out to help us resolve your issue swiftly. Our team is committed to ensuring your satisfaction.