In the rapidly evolving world of technology, managing and optimizing power systems is more crucial than ever. This guide focuses on a sophisticated tool designed to enhance the efficiency and reliability of power management in various applications. Whether you are a seasoned professional or a newcomer, understanding the intricacies of this equipment can significantly improve your operational outcomes.

This comprehensive guide will walk you through the essential aspects of handling the equipment effectively. You’ll gain insights into its core functionalities, explore its various settings, and learn how to tailor the system to meet specific needs. By following these guidelines, you will be well-prepared to maximize the performance and longevity of your power control solution.

Basic Setup for the Equipment Control Unit

To ensure the smooth operation of your power management system, it is crucial to correctly configure the essential settings. This section will guide you through the preliminary adjustments necessary for optimal performance.

First, begin by connecting the power source and verifying that all connections are secure. Once everything is properly connected, you can proceed with the initial configuration. Adjust the voltage and frequency parameters according to the specifications of your application. These settings are fundamental to ensuring that the system operates within the desired range.

Next, calibrate the sensors by following the recommended procedures. This step is important for accurate monitoring of the system’s performance. Once calibration is complete, you can proceed to set up the communication protocols, ensuring that the unit is properly integrated with other components in your setup.

Finally, save your settings and perform a test run to confirm that everything is functioning correctly. If any issues arise during the test, revisit the configuration steps to make the necessary adjustments. Proper setup is key to achieving reliable and efficient performance.

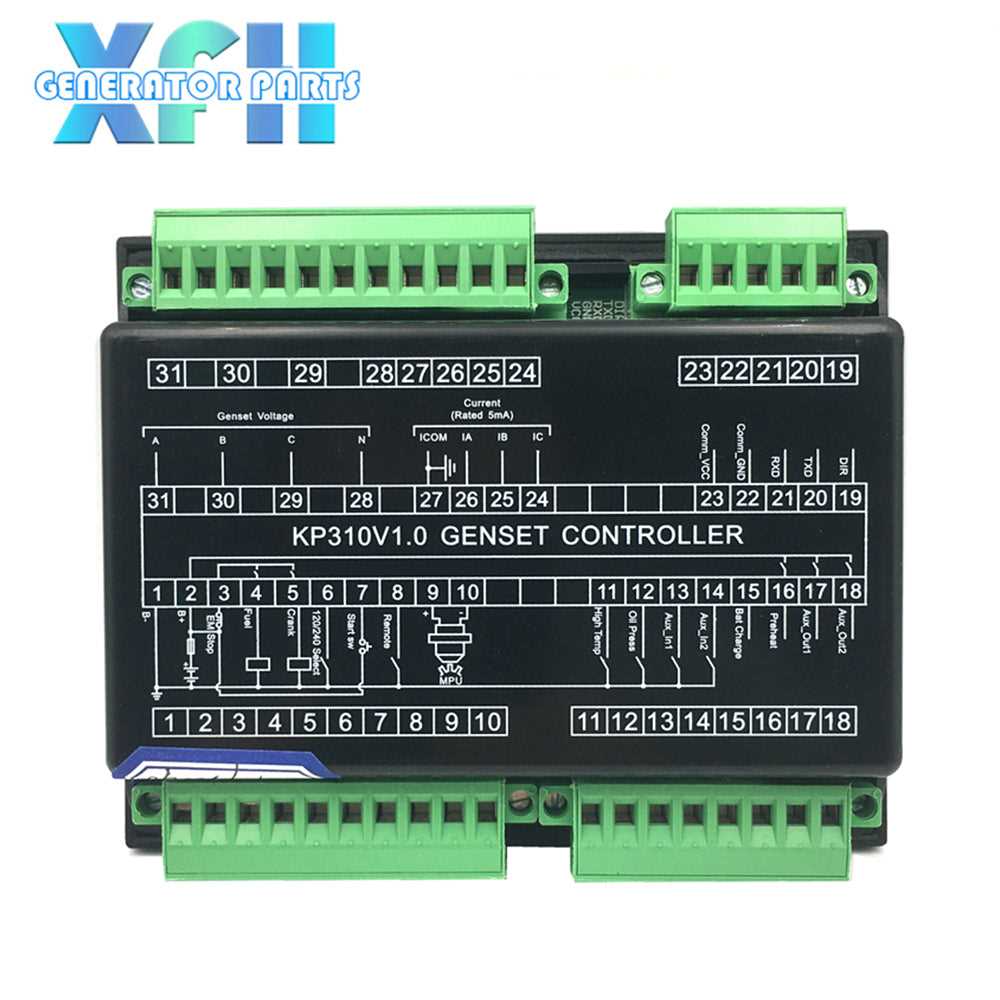

Essential Connections and Wiring Guidelines

Proper connections and wiring are critical to the functionality and safety of any electrical setup. Ensuring that each component is correctly linked can prevent potential hazards and optimize performance. This section outlines the fundamental steps and recommendations for establishing secure and efficient connections.

Key Wiring Considerations

When dealing with electrical connections, it’s important to focus on several key aspects. First, always use cables that are appropriately rated for the current load. Incorrect cable sizing can lead to overheating or even fire risks. Second, make sure all terminals are tightly secured to avoid loose connections, which can cause intermittent power issues.

Grounding and Safety Measures

Grounding is an essential safety measure that protects both the equipment and the user from electrical faults. Always connect the grounding wire to a proper earth point, ensuring that the system is safe and compliant with relevant standards. Additionally, using circuit breakers or fuses in the wiring setup adds an extra layer of protection by automatically disconnecting the power in case of an overload.

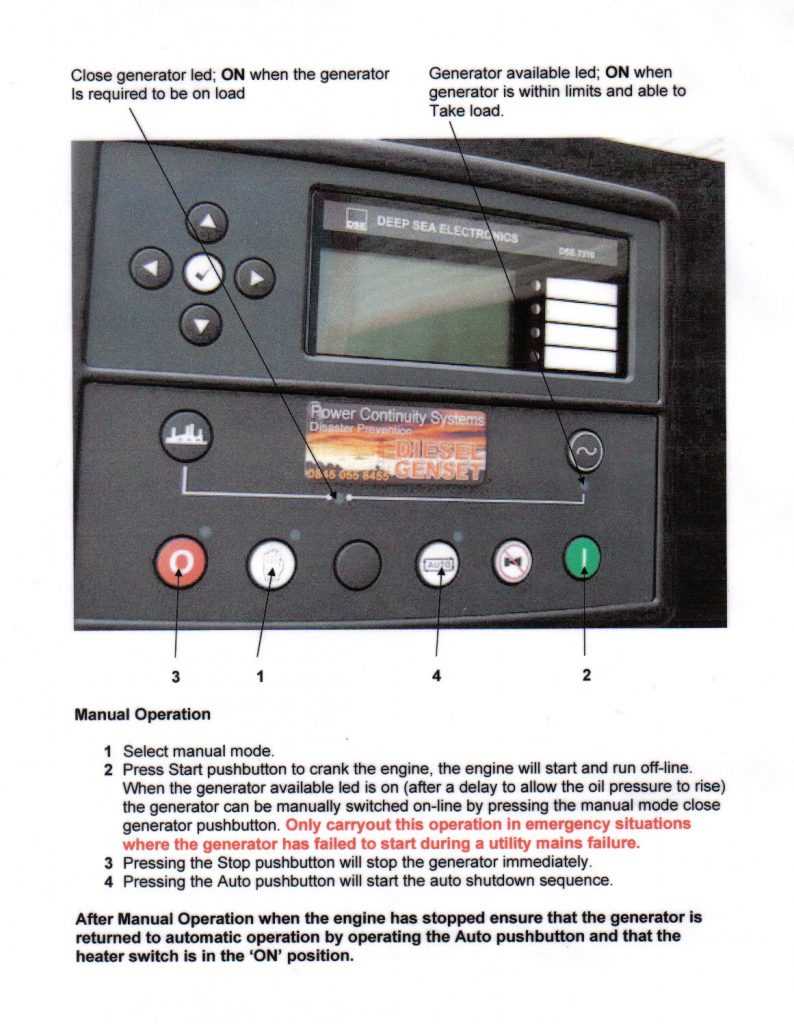

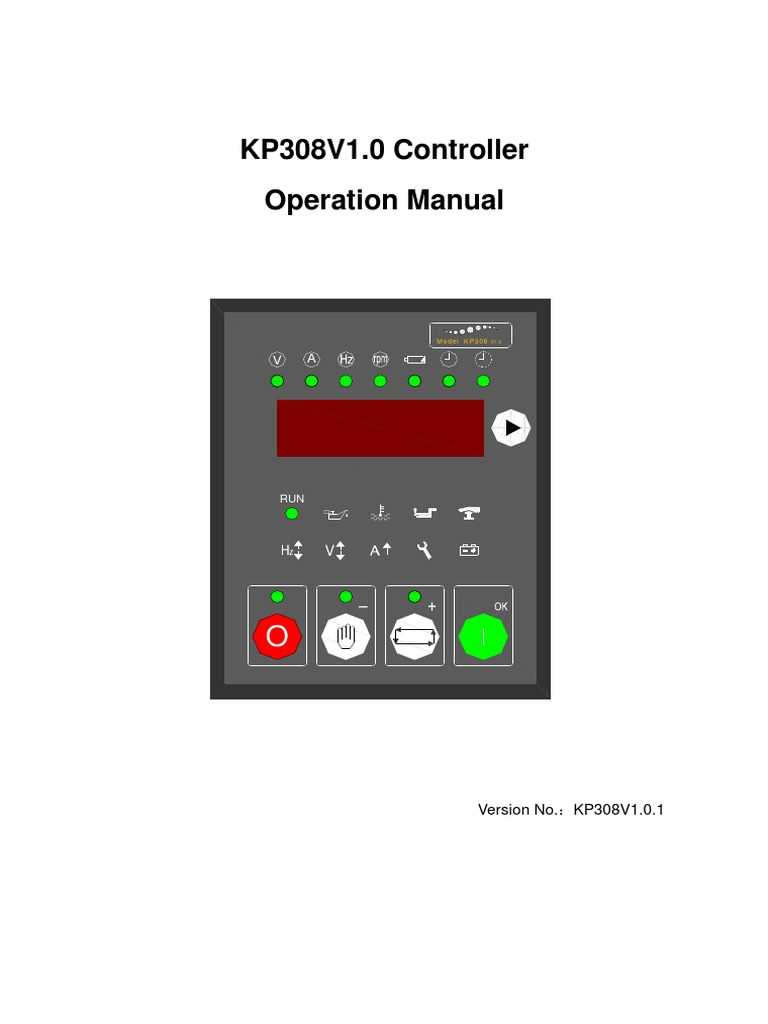

Understanding Display Symbols and Indicators

The interface of many devices features a range of icons and signals that communicate important information. Being able to interpret these symbols effectively is crucial for ensuring proper functionality and addressing potential issues quickly.

Common Visual Cues

On the display, various symbols are designed to provide quick references. These might include indicators for different modes, warning signs, or status updates. Familiarizing yourself with these visuals can greatly enhance your efficiency in monitoring and maintaining the system.

Interpreting Alerts

Indicators often serve as alerts to prompt timely actions. Whether signaling a low resource level, a maintenance requirement, or other system states, understanding these cues enables you to respond appropriately, maintaining optimal performance and avoiding potential malfunctions.

Configuring Generator Settings

Setting up your generator’s parameters is essential for ensuring its optimal performance and efficiency. Properly adjusted settings can enhance reliability, reduce fuel consumption, and extend the lifespan of the equipment. This section will guide you through the key steps in configuring the various options available for your generator system.

First, identify the primary settings that need adjustment, such as voltage, frequency, and power output. These settings must align with the specific requirements of the load that the generator will support. Next, fine-tune the safety thresholds to protect the generator from potential damage due to overload or other adverse conditions. These precautions help prevent unnecessary wear and tear on the machine, thereby maintaining its operational integrity over time.

Additionally, it’s crucial to regularly review and adjust the generator’s settings based on changes in load demands or operational conditions. Periodic reassessment ensures that the system continues to operate within its optimal range, maximizing both efficiency and reliability. By adhering to these guidelines, you can achieve a well-balanced and dependable power solution tailored to your needs.

Troubleshooting Common Issues

Identifying and resolving frequent problems with power management systems can significantly enhance performance and reliability. Effective troubleshooting involves systematically addressing symptoms to pinpoint and correct the root causes. By following a structured approach, users can quickly diagnose and fix common faults, ensuring optimal operation.

1. Power Failure: If the unit fails to power on, check for loose connections or issues with the power source. Verify that all cables are securely connected and inspect the fuse or circuit breaker for any faults.

2. System Overload: An overload condition may arise if the load exceeds the system’s capacity. Reduce the load or adjust the settings to match the system’s specifications to avoid damaging components.

3. Inaccurate Readings: When the readings are inconsistent, calibration errors might be the cause. Recalibrate the system according to the manufacturer’s guidelines to ensure accurate measurements.

4. Communication Failures: Communication issues between the system and external devices can disrupt functionality. Check the communication settings and ensure all connected devices are functioning correctly.

Addressing these common issues promptly can help maintain the system’s efficiency and prevent extended downtime. Regular maintenance and vigilance in troubleshooting can enhance the reliability of the equipment.

Maintenance Tips for Longevity

Ensuring the long-term performance and reliability of your equipment involves regular upkeep and careful attention to key components. By following a few essential practices, you can extend the operational life and maintain the efficiency of your machinery.

Regular Inspections: Conduct frequent checks of all critical parts and systems to identify potential issues before they become major problems. This includes examining connections, fluid levels, and overall wear and tear.

Proper Lubrication: Apply the appropriate lubricants to moving parts according to the manufacturer’s recommendations. Proper lubrication helps reduce friction and prevent premature component failure.

Cleaning: Keep the equipment clean and free of debris. Accumulated dirt and grime can affect performance and lead to overheating or damage.

Timely Replacements: Replace worn or damaged components as soon as possible. Using parts that are compatible with your equipment ensures continued smooth operation.

Record Keeping: Maintain detailed records of maintenance activities, including inspections, repairs, and parts replacements. This helps track the condition of your equipment and plan future upkeep effectively.

By adhering to these maintenance tips, you can help ensure that your equipment remains in optimal condition, minimizing downtime and maximizing its service life.