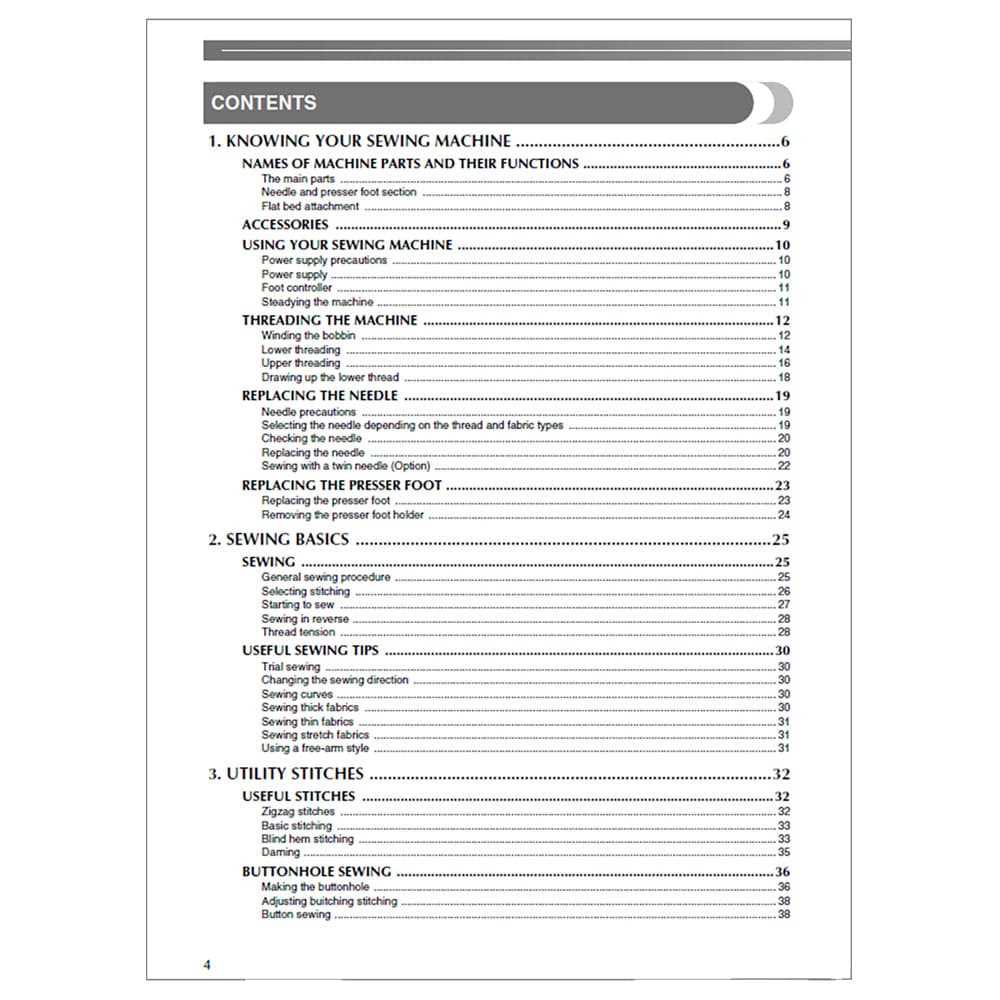

Having reliable equipment is crucial for those who frequently work on various textile projects. Understanding how to fully utilize such a versatile tool can greatly enhance efficiency and results. Whether you’re working on simple repairs or more intricate designs, this guide offers a step-by-step approach to mastering its capabilities.

Learning the ins and outs of this device can be an empowering experience for both beginners and seasoned enthusiasts. It covers everything from initial setup to tackling more advanced features, helping you get the most out of every session.

Explore clear instructions and practical tips that will streamline your tasks, ensuring that your creative process is as smooth as possible. This guide is designed to break down each step in an easy-to-follow manner, making it accessible to users of all skill levels.

Getting Started with the LS2125i

Learning to operate this versatile device is easier than it seems. This section guides you through the essentials, from initial setup to basic functions, ensuring a smooth introduction to its features. Whether you’re a beginner or looking for a quick refresher, following these steps will help you get comfortable with the equipment quickly and effectively.

Unpacking and Setup

Begin by carefully removing all components from the packaging. Ensure that every accessory is accounted for, including needles, foot pedal, and other essential parts. Place the device on a stable, flat surface. Connect the power supply, making sure everything is secure. Adjust the device’s settings as necessary for your first project.

Basic Controls Overview

Before diving into more complex projects, it’s important to familiarize yourself with the primary controls. Below is a quick reference table that explains the key functions.

| Control | Function |

|---|---|

| Stitch Selector | Choose different stitch patterns depending on your project needs. |

| Tension Dial | Adjust thread tension for smooth and consistent results. |

| Reverse Lever | Enables backstitching to reinforce seams. |

| Handwheel | Manually control the needle’s position for precise movements. |

Understanding these core features will allow you to work more confidently and avoid common issues when getting started.

Setting Up Your Device

Before beginning any creative projects, it’s crucial to properly assemble and configure your equipment. Proper setup ensures smooth operation, helping avoid common issues like thread jams or uneven stitching. Below, you’ll find a step-by-step guide to get your unit ready for use.

Start by unpacking all components and making sure everything is accounted for, including essential tools and accessories. Setting the device on a stable surface is key to avoiding unnecessary vibrations during use. Follow these steps to complete the assembly:

| Step | Action |

|---|---|

| 1 | Install the needle securely, ensuring it’s oriented correctly with the flat side facing the right direction. |

| 2 | Insert the bobbin, winding the thread as per the designated path. Be sure the thread is wound evenly and tight. |

| 3 | Attach the spool of thread and guide it through the upper threading path, ensuring the thread passes through each tension mechanism smoothly. |

| 4 | Test the pedal and power connection to verify that the device is operating without issues before starting any practice stitches. |

Once these steps are complete, your equipment should be ready for creative work. Carefully follow each step to ensure optimal performance and longevity.

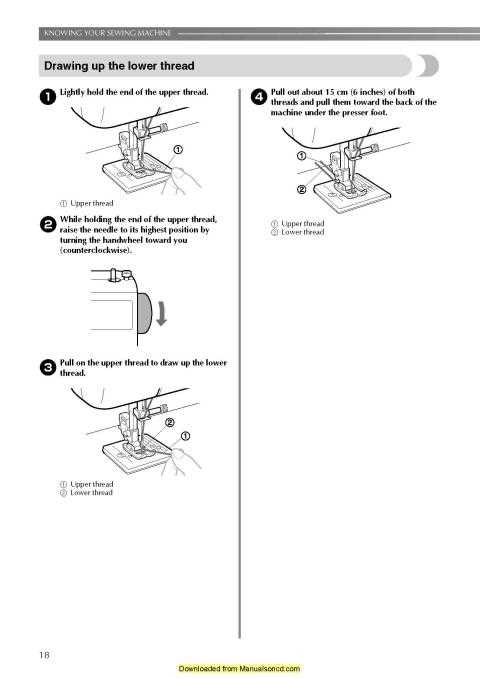

Threading the Needle and Bobbin

Understanding how to properly prepare the upper thread and load the bobbin is key for achieving smooth, even stitches. Correctly threading both components ensures consistent tension and prevents issues like skipped stitches or tangling. Let’s go through the essential steps to set up the thread and bobbin effectively.

Preparing the Upper Thread:

Start by raising the needle and lifting the presser foot. Place the spool on its pin, securing it with the appropriate cap. Guide the thread through the upper threading path, following the indicated guides and tension discs. Make sure the thread passes through the take-up lever and reaches the needle without any twists or slack.

Inserting the Bobbin:

Open the bobbin compartment and place the wound bobbin into its case, ensuring the thread unwinds in the correct direction. Pull the thread through the slot and guide it under the tension spring, leaving a short tail. Close the compartment cover, and you’re ready to draw the bobbin thread up by turning the handwheel.

With both threads in place, you’re set to begin stitching with confidence, knowing the setup is correctly aligned for optimal performance.

Understanding Stitch Options and Settings

When working on different projects, it’s essential to grasp the available stitch types and how to adjust them. A proper understanding of these options allows you to handle various fabrics and techniques effectively, ensuring precise and neat results. Adjusting the settings correctly can significantly impact the durability and appearance of your work.

Types of Stitches

Most models offer a range of basic and decorative stitches. The common ones include straight, zigzag, and specialty options for specific tasks like hemming or finishing edges. Each type has its ideal use, whether you need strong seams, flexibility, or a particular aesthetic effect.

Adjusting Stitch Length and Width

The length and width settings play a key role in customizing stitches to match your material and purpose. Shorter lengths are typically chosen for delicate fabrics or tighter seams, while longer settings work better for basting or gathering. Width adjustments, primarily for zigzag stitches, control how broad or narrow the stitch appears, allowing more flexibility in design and function.

Maintenance Tips for Smooth Operation

Regular upkeep is essential to ensure that your device functions reliably and performs at its best over time. Proper care helps prevent malfunctions, extends the lifespan of the equipment, and ensures consistent results. The following guidelines cover key practices to maintain smooth and efficient operation.

Keep It Clean: Dust and debris can accumulate inside the device, leading to performance issues. Regularly remove loose threads, lint, and other particles, especially from areas prone to buildup. This simple habit reduces the risk of jamming and ensures more fluid movement.

Timely Lubrication: Moving parts require appropriate lubrication to maintain seamless operation. Use a recommended oil sparingly on metal components where friction is involved. Excess oil can attract more dust, so apply it carefully and wipe away any excess.

Check for Wear and Tear: Regularly inspect key elements, such as needles and belts, for signs of wear. Replace damaged or worn parts promptly to prevent further issues and ensure consistent results.

Proper Storage: When not in use, store your device in a dust-free environment and cover it to protect from contaminants. Proper storage conditions help preserve the integrity of both internal mechanisms and external surfaces.

By integrating these simple maintenance habits into your routine, you can achieve more reliable performance and extend the device’s operational life.

Troubleshooting Common Sewing Issues

Understanding how to resolve frequent problems that arise during fabric crafting can make your stitching projects more enjoyable and efficient. Addressing these common concerns can help ensure smoother operation and better results in your creations. This section provides guidance on how to identify and fix typical complications that might occur while working on your projects.

Needle Problems

Needle issues can often disrupt your workflow. Here are some common problems and their solutions:

- Needle is Bent or Broken: Always check if the needle is bent or damaged. Replace it with a new one if necessary.

- Incorrect Needle Type: Ensure that you are using the correct needle type and size for your fabric and thread. Consult your sewing tool’s specifications for recommendations.

- Needle Not Properly Inserted: Verify that the needle is installed correctly and securely. A needle that is not properly seated can cause stitching issues.

Threading Issues

Threading problems can lead to various complications. Here’s how to troubleshoot them:

- Thread Breaking: This can occur due to improper tension settings or using poor-quality thread. Adjust the tension and ensure you’re using high-quality thread.

- Thread Jamming: Check for thread tangles or snags in the threading path. Clear any obstructions and re-thread as needed.

- Uneven Stitching: Ensure that both the upper and lower threads are correctly threaded and that the bobbin is properly wound and inserted.

By addressing these common issues, you can enhance the performance and longevity of your crafting tool, leading to better outcomes in your projects. Regular maintenance and careful troubleshooting are key to achieving optimal results.