The following content provides essential guidance on the efficient operation and maintenance of a specific component utilized in fluid circulation systems. Understanding the key features and functionalities of this equipment can enhance overall performance and ensure optimal flow management.

In this section, we will explore the various aspects of handling this device, including installation procedures, troubleshooting techniques, and safety precautions. Proper handling is crucial to maintain the integrity of the entire system and to prevent any potential disruptions in service.

We emphasize the importance of adhering to recommended practices and utilizing the provided resources for effective utilization. By following these guidelines, users can achieve seamless operation and prolong the lifespan of the equipment.

Overview of Bell & Gossett Products

This section provides a comprehensive insight into the offerings from a leading manufacturer in the industry, renowned for its innovative solutions in fluid handling and system efficiency. The company specializes in a wide range of equipment designed to enhance performance, reliability, and sustainability across various applications.

The product line includes components crucial for effective water distribution and energy conservation, serving both residential and commercial sectors. Each item is engineered with precision to meet the highest standards of quality and efficiency.

| Product Type | Description | |||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Pumps | Devices designed to move fluids by mechanical action, often using electricity. | |||||||||||||

| Valves | Control the flow and pressure within a system, ensuring optimal performance. | |||||||||||||

| Issue | Possible Cause | Suggested Solution |

|---|---|---|

| Reduced Fluid Flow | Clogged filters or obstructed pipes | Check and clean filters; inspect and clear any blockages in the pipes. |

| Unusual Noise | Loose components or air trapped in the system | Tighten all fittings and components; bleed the system to remove trapped air. |

| Leakage | Damaged seals or loose connections | Inspect seals for damage and replace if necessary; tighten all connections securely. |

| Poor Performance | Improper installation or incorrect settings | Review installation instructions and adjust settings as needed to ensure correct operation. |

Regular maintenance and timely intervention can help in mitigating these issues. Always consult the relevant guidelines and seek professional assistance if needed to resolve complex problems effectively.

Benefits of Using Suction Diffusers

Implementing a component designed to evenly distribute flow in a fluid system provides several advantages, enhancing overall system performance and reliability. By integrating such a device, users can achieve more balanced operation and improved efficiency in their systems.

- Improved Fluid Distribution: These devices help in managing and distributing the flow of fluids more evenly, reducing turbulence and preventing localized high-velocity areas. This results in smoother and more consistent fluid movement.

- Reduced Noise Levels: By mitigating the effects of fluid turbulence, these components help in lowering the noise generated by the fluid flow, contributing to a quieter and more comfortable environment.

- Enhanced Equipment Longevity: Even distribution of flow minimizes the risk of damage caused by sudden changes in velocity or pressure. This contributes to the extended lifespan of connected equipment and reduces maintenance requirements.

- Improved System Efficiency: With balanced fluid flow, the overall efficiency of the system is increased. Proper management of flow leads to better energy use and can result in cost savings over time.

- Prevention of Air Lock: By ensuring proper flow distribution, these components help in preventing the formation of air pockets that can impede system performance and cause operational issues.

Incorporating these devices into your fluid handling systems can lead to a range of benefits, from quieter operation to enhanced equipment durability and improved efficiency. Their role in optimizing fluid flow makes them a valuable addition to many industrial and commercial applications.

Frequently Asked Questions About Installation

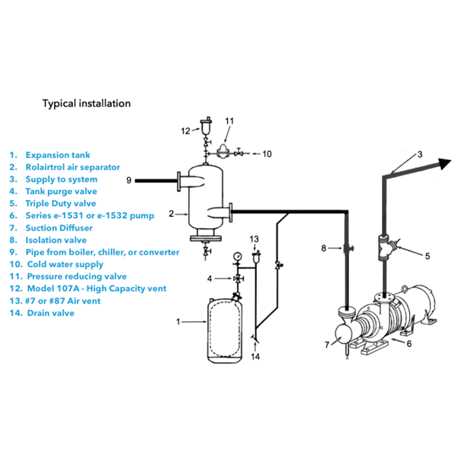

When setting up a new component in your system, it’s common to have questions about the best practices and procedures. This section aims to address some of the most common inquiries regarding the installation process to help ensure a smooth and efficient setup.

Q: What preparation should I do before starting the installation?

A: Before beginning the installation, ensure that you have all necessary tools and parts. It’s also important to review the specifications of your system to confirm compatibility and to prepare the installation area by clearing any obstructions.

Q: How do I ensure proper alignment during installation?

A: Accurate alignment is crucial for optimal performance. Use alignment tools and check the component’s level and position according to the guidelines provided. Make adjustments as needed to align the component correctly with existing system elements.

Q: Are there any common mistakes to avoid during installation?

A: Yes, common mistakes include improper alignment, insufficient tightening of connections, and neglecting to check for leaks or other issues after installation. Always follow the recommended procedures closely and double-check your work to avoid these pitfalls.

Q: How should I handle system pressure testing?

A: After installation, conduct a pressure test to ensure that there are no leaks and that the component is functioning properly. Follow the manufacturer’s guidelines for the pressure levels to be used and monitor for any irregularities.

Q: What should I do if I encounter issues during installation?

A: If you encounter problems, first review the installation instructions to ensure that you haven’t missed any steps. If issues persist, consult the troubleshooting section of the documentation or contact customer support for further assistance.