In today’s fast-paced world, having a reliable cooling system is more essential than ever. As temperatures rise, understanding how to efficiently operate your cooling unit can make all the difference in maintaining a comfortable and refreshing environment. This guide provides you with everything you need to know to get the most out of your cooling solution.

Whether you’re setting up a new device or simply looking to enhance its performance, it’s crucial to follow the right steps and be aware of the best practices. Proper utilization not only ensures optimal results but also prolongs the lifespan of your equipment. This guide walks you through the key aspects, offering clear and concise directions.

Efficiency, durability, and ease of use are at the heart of any successful cooling experience. By familiarizing yourself with the essential functions and settings, you’ll be well-equipped to create a cool and comfortable space, no matter the season. Let’s explore the necessary steps to achieve a seamless and effective cooling process.

Understanding the Basics of Arctic Air

The primary objective of this section is to provide a fundamental grasp of the principles behind the system you’re using. This will help you navigate its functions more effectively and ensure optimal performance in various environments.

Key Components

The system is built with several crucial parts that work together to achieve the desired temperature regulation. Familiarizing yourself with these components will allow for better maintenance and troubleshooting when necessary.

- Cooling Unit: The core element responsible for lowering the surrounding temperature.

- Reservoir: A container that holds liquid, essential for the cooling process.

- Control Panel: Interface used to adjust settings and monitor the system’s operation.

How It Works

Understanding the operational flow of the system can greatly enhance your experience. Below is a simplified explanation:

- The cooling unit draws in warm air and passes it through a filter.

- The filtered air is then cooled by a process that involves the absorption of heat by the liquid in the reservoir.

- Finally, the cooler air is circulated back into the environment, effectively reducing the overall temperature.

By comprehending these basics, you will be better equipped to utilize the system to its fullest potential.

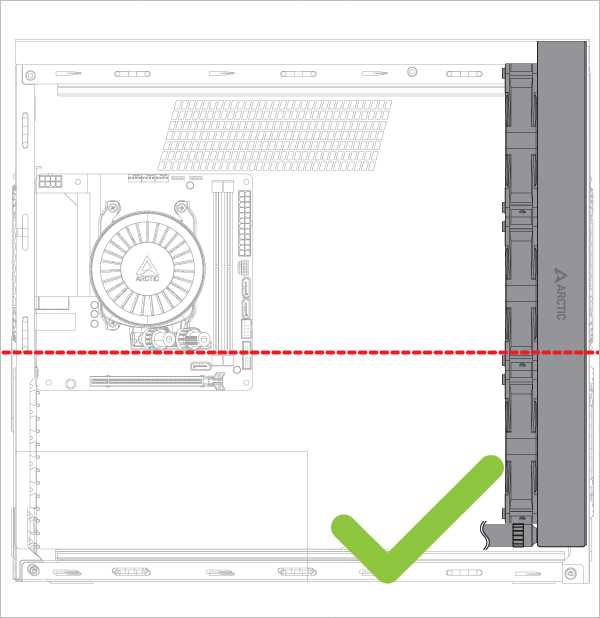

Initial Setup and Installation Tips

Setting up your device for optimal performance requires careful attention to detail. Proper installation is essential for ensuring longevity and functionality, and following the correct steps can prevent potential issues down the line.

Choosing the Right Location

Find a stable, flat surface where the unit can operate without obstruction. Ensure that the area is well-ventilated and free from direct sunlight, as excessive heat can impact efficiency. Avoid placing the unit near any sources of moisture to prevent potential damage.

Connecting Power Safely

Before plugging in the device, verify that the power source matches the required specifications. Use a grounded outlet to reduce the risk of electrical faults. It is recommended to avoid using extension cords to prevent power surges and ensure a stable connection.

By following these installation tips, you can maximize the efficiency and lifespan of your equipment, ensuring it operates smoothly in your environment.

Optimizing Performance for Best Results

Maximizing the efficiency of your system is key to achieving optimal outcomes. By fine-tuning specific settings and maintaining the proper conditions, you can significantly enhance overall functionality and ensure reliable, long-term operation.

Temperature Control: Consistently monitor and adjust the temperature settings to match the current environment. Proper calibration prevents strain on the system, promoting smooth and efficient performance.

Routine Maintenance: Regularly inspect and clean the components to prevent build-up and wear. Timely maintenance prolongs the life of the equipment and ensures it operates at peak capacity.

Power Management: Ensure the power source is stable and uninterrupted. Avoid frequent power cycles, which can lead to unnecessary stress on the system. A steady power supply contributes to consistent and optimal functionality.

Environmental Factors: Keep the surrounding area free from obstructions and ensure adequate ventilation. Proper airflow reduces the risk of overheating, maintaining efficient performance over extended periods.

By adhering to these guidelines, you can maintain high levels of efficiency and reliability, resulting in better overall performance and longevity.

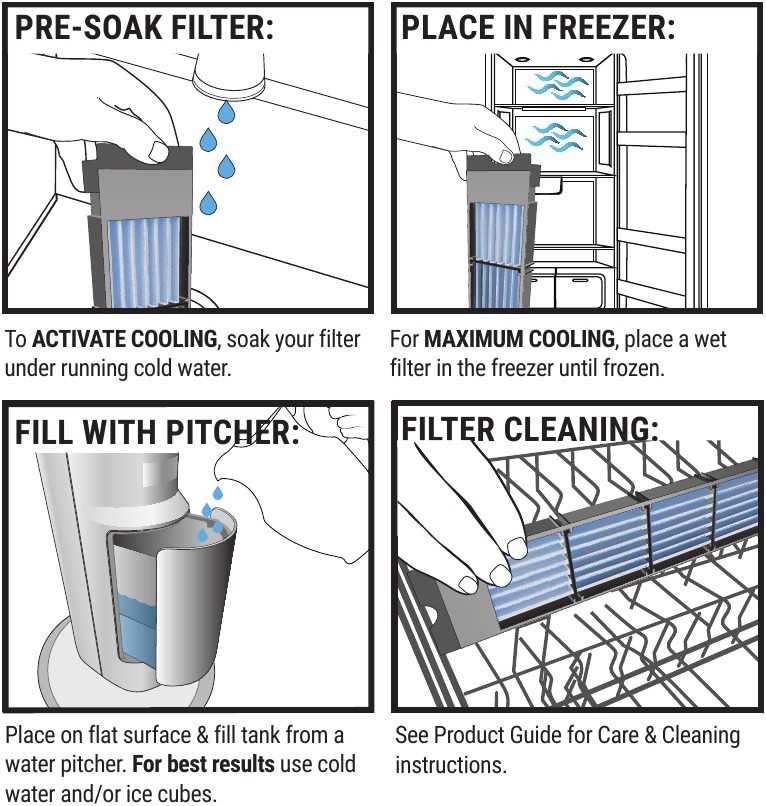

Regular Maintenance and Cleaning Guide

Consistent upkeep and thorough cleaning are essential to ensure the efficient and long-lasting operation of your equipment. By adhering to a routine maintenance schedule, you can prevent potential issues, optimize performance, and extend the lifespan of the unit.

Filter Care: The filter is a critical component that needs regular attention. Inspect the filter monthly for dust accumulation and other debris. If the filter appears clogged, remove it and clean it with warm water and mild detergent. Allow it to dry completely before reinstalling.

External Surfaces: The exterior of the device should be kept clean to avoid the buildup of dust and grime. Wipe down the outer casing with a soft, damp cloth. Avoid using abrasive cleaners that could damage the surface.

Internal Components: Over time, internal parts may gather dust, which can impede functionality. Periodically, check inside the unit for any signs of dust buildup or obstructions. Use a vacuum with a soft brush attachment to gently remove any dirt.

Draining Excess Moisture: If your unit collects water during operation, regularly empty the reservoir to prevent mold growth. Clean the reservoir with warm water and a mild disinfectant, ensuring it is dry before reattaching.

Professional Servicing: For more complex maintenance tasks, consider scheduling professional service. A qualified technician can perform a detailed inspection, addressing any components that require expert attention.

Troubleshooting Common Issues and Solutions

Encountering operational challenges can be frustrating, but many common issues have straightforward solutions. This guide provides practical advice to help resolve typical problems efficiently and effectively, ensuring optimal performance.

Frequent Operational Problems

Here are some of the most frequently reported issues along with suggested resolutions. These solutions can help restore functionality and maintain consistent performance.

| Problem | Possible Cause | Solution |

|---|---|---|

| Unit not turning on | Power supply not connected | Ensure the power cord is securely plugged in and the outlet is functional. |

| Insufficient cooling | Blocked airflow | Check for obstructions around the unit and clear any blockages to improve air circulation. |

| Strange noises during operation | Loose components | Inspect the unit for any loose parts and tighten them as necessary. |

| Water leakage | Clogged drainage system | Clean the drainage path to ensure proper water flow. |

Advanced Troubleshooting

If basic troubleshooting does not resolve the issue, more detailed examination may be required. This could involve checking internal components or contacting professional support for further assistance.

Enhancing Efficiency in Different Conditions

Optimizing performance across varied environments involves understanding and adapting to diverse operational settings. By employing tailored strategies and leveraging specific adjustments, one can significantly improve the effectiveness and longevity of systems. Such adaptations are crucial for ensuring reliable functionality regardless of external factors.

Implementing specialized configurations for unique conditions can greatly influence overall performance. This includes adjusting settings to accommodate temperature fluctuations, humidity levels, or other environmental factors. Customizing operational parameters to align with the specific demands of different situations ensures that equipment remains effective and efficient.

Additionally, regular maintenance and monitoring play a vital role. Proactive upkeep helps in identifying potential issues before they impact performance. By staying vigilant and making necessary adjustments, one can maintain optimal efficiency and prevent disruptions.