When working with power tools, having a comprehensive understanding of their operation is crucial for achieving optimal results and ensuring safety. This guide serves as a resource for navigating the features and functions of these devices, providing step-by-step directions to assist both novice and experienced users.

Detailed explanations will cover various aspects of the tool, from basic setup and adjustments to advanced techniques. With clear instructions and practical advice, users will be equipped to handle the equipment effectively, maximizing both performance and longevity.

Whether you are a DIY enthusiast or a professional tradesperson, mastering the proper use of your tools is essential. This resource aims to enhance your skills and confidence, enabling you to complete your projects with precision and ease.

Understanding Your Makita Drill

Gaining familiarity with your power tool involves exploring its key features and functionalities. This insight will ensure you use it effectively and safely for a variety of tasks. Whether you’re a novice or experienced user, recognizing how each component contributes to its overall performance is crucial.

Begin by examining the core components of the tool. These typically include the handle, trigger, and various control settings. Understanding these parts will help you operate the device smoothly and address any operational issues that may arise.

The settings and adjustments available on your tool enable you to tailor its performance to different tasks. Familiarize yourself with these options to maximize efficiency and achieve the best results in your projects. Each setting plays a role in enhancing the tool’s versatility and effectiveness.

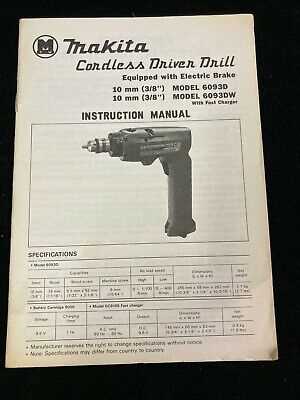

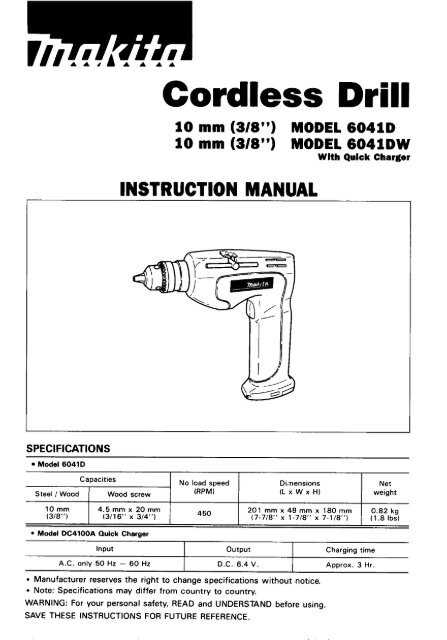

Key Features and Specifications

Understanding the primary attributes and technical details of a power tool is essential for making an informed decision. This section outlines the crucial features and specifications that define the performance and usability of the equipment. By examining these elements, users can better gauge the tool’s suitability for their specific tasks and applications.

Essential Attributes

- Power Source: The type of power supply the tool requires, whether it’s battery-operated or corded.

- Speed Settings: The range of speed options available, often adjustable to suit various tasks.

- Torque Control: Features that allow for the adjustment of rotational force, crucial for different materials and applications.

- Chuck Size: The diameter of the chuck, which determines the range of bits that can be used.

- Ergonomics: Design elements that affect user comfort and ease of use during prolonged periods of operation.

Technical Specifications

- Voltage: The electrical voltage required to operate the tool, affecting its power and efficiency.

- Maximum Speed: The highest rotational speed achievable, measured in RPM (revolutions per minute).

- Battery Capacity: For cordless models, the capacity of the battery, typically measured in ampere-hours (Ah).

- Weight: The overall weight of the tool, influencing its portability and handling.

- Dimensions: The physical dimensions of the tool, which can impact its storage and maneuverability.

Step-by-Step Setup Guide

Proper assembly and configuration are crucial for achieving optimal performance and safety with your new power tool. This guide will walk you through each phase of setting up your equipment, ensuring that you are fully prepared for efficient and safe use.

- Unpacking and Inspection:

- Carefully remove all components from the packaging.

- Verify that all parts listed in the parts list are present and undamaged.

- Inspect the tool for any signs of shipping damage or defects.

- Assembly:

- Attach the main components according to the provided diagrams.

- Ensure all screws and bolts are tightened securely, but avoid over-tightening.

- Check for proper alignment and stability of assembled parts.

- Power Source Connection:

- Connect the tool to the appropriate power source as specified.

- Verify that all electrical connections are secure and free of damage.

- Ensure the power source is compatible with the tool’s requirements.

- Initial Calibration:

- Adjust settings to the recommended specifications for initial use.

- Perform a test operation to verify correct calibration.

- Make any necessary adjustments based on test results.

- Safety Checks:

- Review all safety features and ensure they are functioning correctly.

- Read through the safety instructions to familiarize yourself with operational guidelines.

- Wear appropriate personal protective equipment before use.

lessCopy code

Essential Operating Techniques

Mastering the fundamental techniques for operating power tools is crucial for both efficiency and safety. Proper handling ensures optimal performance and prolongs the tool’s lifespan. In this section, we will cover key practices to enhance your proficiency and ensure effective results.

Tool Handling and Control

Proper grip and control are vital when working with power equipment. Always hold the tool firmly with both hands to maintain stability. Ensure that your grip is secure but not overly tight, as excessive force can lead to fatigue and reduced accuracy. Adjust your stance to maintain balance and control during operation.

Speed and Pressure Management

Applying the correct amount of pressure and adjusting the speed settings according to the material being worked on is essential. Start with lower speeds and gradually increase as needed. Applying too much pressure can damage the tool and the work surface, while insufficient pressure may result in ineffective performance.

By adhering to these techniques, you will ensure safe and efficient operation, achieving better results and extending the longevity of your equipment.

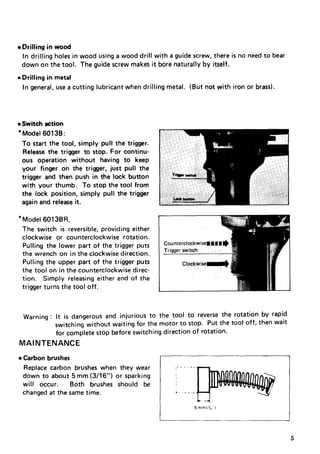

Common Maintenance Practices

Proper upkeep of your power tool ensures its longevity and optimal performance. Regular maintenance routines are essential for keeping the equipment in top condition, preventing breakdowns, and extending its lifespan. By following a few straightforward procedures, you can maintain efficiency and avoid costly repairs.

Here are some essential practices to follow:

| Task | Description | Frequency |

|---|---|---|

| Clean the Tool | Remove dust and debris from the tool’s exterior and vents using a soft brush or cloth. | After each use |

| Check and Tighten Screws | Inspect all screws and fasteners for looseness and tighten them as needed to ensure stability. | Weekly |

| Inspect the Cord | Examine the power cord for any signs of wear or damage. Replace if necessary. | Monthly |

| Lubricate Moving Parts | Apply appropriate lubricant to moving parts to ensure smooth operation and reduce friction. | Every few months |

| Check Brushes | Inspect and replace worn carbon brushes to maintain electrical efficiency. | Every 6 months or as needed |

Troubleshooting Common Issues

When working with power tools, encountering problems is not uncommon. Addressing these issues promptly can help ensure smooth operation and extend the lifespan of the equipment. This section provides guidance on identifying and resolving frequent challenges faced by users. Whether it’s inconsistent performance or unexpected malfunctions, understanding common problems and their solutions can make your tasks more efficient and hassle-free.

One of the typical issues might be a lack of power or insufficient performance. This can often be traced back to problems with the power source or the tool’s internal components. Ensure that the battery or power cord is in good condition and properly connected. If the tool still fails to operate correctly, there may be an issue with the motor or other critical parts that might need professional attention.

Another frequent concern is unusual noise or vibration during use. This can indicate wear and tear or misalignment of internal parts. Check for any loose or damaged components and ensure that the tool is properly assembled. Regular maintenance and proper handling can help minimize these problems.

Finally, overheating is a sign that the tool may be overworked or poorly ventilated. Allow the equipment to cool down if it becomes excessively hot and ensure that the ventilation openings are not blocked. Proper usage according to the manufacturer’s guidelines will help prevent such issues.

Safety Tips and Best Practices

Ensuring safe and effective operation of power tools is crucial for both personal safety and optimal performance. Following a set of guidelines can help prevent accidents and extend the lifespan of your equipment. Adhering to these practices ensures that you work efficiently and safely, minimizing the risk of injuries and damage to the tool.

General Safety Measures

Before starting any task, make sure you are familiar with the operation of your equipment. Always wear appropriate protective gear such as safety glasses, gloves, and hearing protection. Keep your workspace clean and well-lit to avoid any tripping hazards or accidental contact with moving parts. Ensure that your tools are properly maintained and free of defects before use. Never bypass safety features or attempt to use damaged equipment.

Operational Best Practices

When engaging in work, maintain a firm grip and a stable stance to control the tool effectively. Avoid applying excessive force; let the tool do the work. Be cautious of your surroundings and ensure that there are no obstacles or people nearby who could be harmed. After completing a task, disconnect the tool from the power source and store it safely. Regularly inspect the tool for wear and tear and perform necessary maintenance to keep it in good working condition.

By adhering to these guidelines, you ensure not only your safety but also the efficient performance of your equipment.