In the realm of advanced dermatological procedures, achieving optimal results relies heavily on the proper use of specialized equipment. This guide aims to offer a thorough understanding of a cutting-edge device designed for precise skin interventions. Whether you’re a seasoned professional or new to the field, mastering this tool can significantly enhance the effectiveness and efficiency of your work.

We delve into the features and functionality of this sophisticated apparatus, focusing on its innovative design and application techniques. By familiarizing yourself with the operational nuances and maintenance protocols, you can ensure that the device performs at its best, delivering consistent and reliable outcomes in your treatments.

Our exploration covers essential aspects, from setup and calibration to troubleshooting common issues. This resource is intended to equip you with the knowledge necessary to harness the full potential of this advanced instrument, ultimately leading to superior patient care and procedural success.

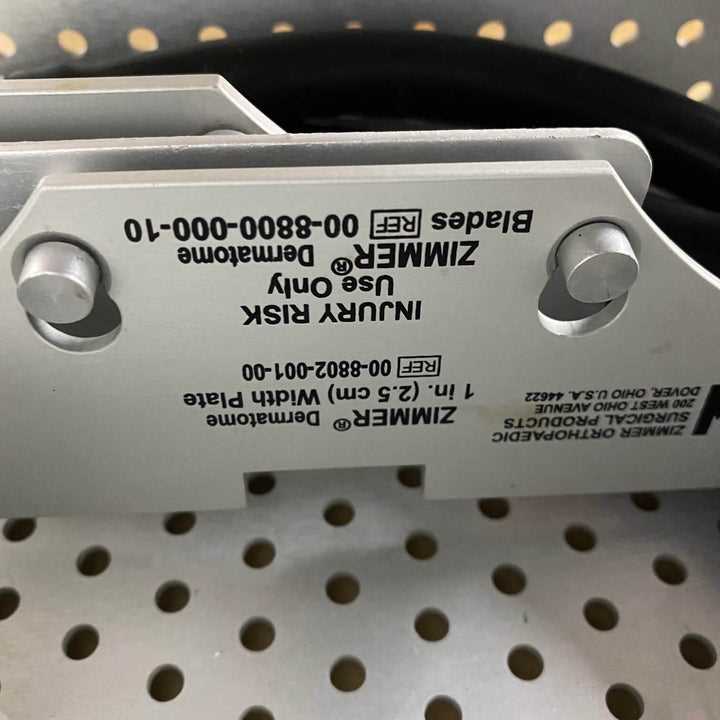

Overview of Dermatological Skin Grafting Tool

The dermatological skin grafting tool is a sophisticated instrument designed to enhance precision in the field of skin transplantation. This device is pivotal for achieving consistent and accurate skin layers during grafting procedures. It offers a streamlined approach to harvesting skin grafts, ensuring minimal damage to the donor site and maximizing the quality of the grafts obtained.

Features and Functionality

This tool integrates advanced technology to provide an efficient and controlled method of graft extraction. Its ergonomic design allows for ease of use, with adjustable settings to accommodate various skin types and desired graft thicknesses. The mechanism ensures uniform cutting, which is crucial for optimal graft integration and healing.

Applications and Benefits

Utilized extensively in both medical and cosmetic dermatology, this device plays a crucial role in procedures that require precise skin grafting. It supports rapid recovery of patients by minimizing trauma to the donor site and enhancing the overall outcome of the grafting process. The tool’s reliability and effectiveness make it an essential asset in skin restoration and reconstructive surgeries.

Understanding Its Purpose and Benefits

In the realm of medical equipment, certain devices are designed to facilitate precision and efficiency during procedures. These tools play a crucial role in enhancing the accuracy of surgical tasks and improving patient outcomes. They are engineered to streamline operations and offer various advantages that can significantly impact both the procedural approach and the overall effectiveness of treatment.

One of the primary advantages of these specialized instruments is their ability to provide consistent and controlled performance. This ensures that the desired results are achieved with minimal risk of complications. By utilizing these tools, medical professionals can benefit from enhanced precision, which is essential for successful outcomes in complex procedures.

Moreover, these devices are designed with user convenience in mind, incorporating features that reduce the effort and time required for various tasks. This not only contributes to a smoother workflow but also improves the overall efficiency of medical practices. The integration of these advanced tools into clinical settings reflects a commitment to advancing medical technology and delivering superior care.

| Feature | Benefit |

|---|---|

| Precision Engineering | Ensures accurate and reliable outcomes |

| Ease of Use | Streamlines procedures and reduces effort |

| Efficiency | Enhances workflow and saves time |

Key Features and Specifications

This section provides an overview of the essential attributes and technical details of the device. Understanding these aspects is crucial for ensuring optimal performance and selecting the right equipment for medical procedures. The following features and specifications highlight the core functionalities and design elements that contribute to the device’s effectiveness and reliability.

Core Functionalities

- Precision Control: The device offers advanced precision control mechanisms to ensure accurate and consistent results.

- Adjustable Settings: Multiple adjustable settings allow customization based on specific procedural needs.

- Ergonomic Design: Designed with user comfort in mind, facilitating ease of use during extended procedures.

- Efficiency: Optimized for high efficiency and minimal downtime, contributing to enhanced workflow.

Technical Specifications

- Power Source: The device operates on a reliable power source to ensure stable performance.

- Dimensions: Compact dimensions make it easy to handle and store.

- Weight: Lightweight construction for better maneuverability and user comfort.

- Material: Constructed from durable materials to withstand frequent use and maintain longevity.

What Makes It Unique?

In the realm of medical instruments, certain devices stand out due to their exceptional design and functionality. This particular tool distinguishes itself through a combination of advanced engineering and user-centric features. Its innovative approach not only enhances performance but also simplifies the procedures for medical professionals.

The uniqueness of this device lies in its sophisticated mechanism that allows for precise adjustments and consistent results. Its ergonomic design ensures ease of use, which is crucial during delicate operations. Additionally, the integration of cutting-edge technology facilitates seamless operation, setting a new standard in its category.

Overall, its distinctive attributes contribute to improved efficiency and effectiveness in medical procedures, making it a valuable asset in clinical settings.

Step-by-Step Operating Instructions

Following a systematic approach is crucial when using sophisticated medical equipment. This section provides a detailed guide to ensure proper handling and functionality of the device. Each stage in the operation is outlined to help you achieve optimal results while maintaining safety and efficiency.

- Preparation:

- Ensure that the equipment is clean and free from any obstructions.

- Verify that all components are correctly assembled and in good working condition.

- Confirm that the power source is properly connected and functional.

- Adjustment:

- Set the desired parameters based on the procedure requirements.

- Adjust the settings to match the specifications needed for the task.

- Double-check all adjustments to ensure accuracy before proceeding.

- Operation:

- Begin the operation by following the specific sequence outlined in the guidelines.

- Monitor the device continuously to ensure it is functioning as expected.

- Make any necessary adjustments promptly to maintain optimal performance.

- Post-Operation:

- Carefully turn off the equipment and disconnect the power source.

- Clean and store the device according to the prescribed procedures.

- Perform a routine check to confirm that all parts are in order for future use.

How to Use the Device Properly

Ensuring the effective operation of a precision cutting tool involves following specific guidelines to achieve optimal results. Proper handling and preparation are crucial to maintaining both the quality of the procedure and the safety of the user. Adhering to these practices will help maximize the performance and longevity of the equipment.

First, it is important to familiarize yourself with the device before use. Review all components and settings to ensure they are functioning correctly. Proper setup includes adjusting the device to the appropriate settings for the task at hand, as well as ensuring that all parts are securely in place.

During operation, handle the device with care. Maintain a steady hand and follow the recommended techniques to ensure consistent and accurate cuts. Avoid applying excessive force, as this can affect both the quality of the cut and the durability of the device.

After completing the procedure, clean the device thoroughly. This involves removing any debris and checking for any signs of wear or damage. Regular maintenance will prolong the life of the device and ensure it continues to perform effectively.

| Step | Action | Details |

|---|---|---|

| 1 | Inspect | Check all components and settings before use. |

| 2 | Setup | Adjust settings according to the task requirements. |

| 3 | Operate | Handle with care, use recommended techniques, avoid excessive force. |

| 4 | Clean | Remove debris and inspect for wear or damage after use. |

Maintenance and Troubleshooting Tips

Regular upkeep and prompt problem resolution are essential for ensuring the optimal performance and longevity of your equipment. This section provides guidance on how to maintain the device in peak condition and addresses common issues that may arise during its use. Proper care and timely interventions can prevent malfunctions and extend the lifespan of your tool.

Routine Maintenance

To keep your equipment functioning smoothly, follow these routine maintenance practices:

- Regularly clean the surfaces and components to avoid buildup that may affect performance.

- Inspect the device for any signs of wear or damage and replace parts as necessary.

- Ensure that all moving parts are properly lubricated according to the manufacturer’s recommendations.

- Check and calibrate the equipment periodically to maintain accuracy and efficiency.

Troubleshooting Common Issues

Here are some common issues you might encounter and their potential solutions:

| Issue | Possible Cause | Solution |

|---|---|---|

| Inconsistent performance | Dirty or clogged components | Clean the affected parts thoroughly and ensure proper airflow. |

| No response from the device | Power supply issue or disconnected cables | Check the power source and connections; ensure everything is securely plugged in. |

| Excessive noise during operation | Lack of lubrication or worn parts | Lubricate moving parts and inspect for any worn-out components that need replacement. |

By adhering to these maintenance routines and addressing issues promptly, you can enhance the performance and reliability of your equipment, ensuring it operates effectively for years to come.

Ensuring Longevity and Performance

To maximize the lifespan and efficiency of your surgical tool, regular maintenance and proper usage are key. Understanding and implementing effective care practices will not only enhance the instrument’s performance but also extend its operational life, ensuring reliable functionality in critical situations.

Routine Cleaning and Sterilization: Proper cleaning and sterilization after each use are essential. Follow the recommended procedures to remove debris and avoid corrosion. Use appropriate cleaning agents and ensure thorough drying to prevent any potential damage.

Regular Inspection: Frequent checks for wear and tear can prevent unexpected malfunctions. Examine all components for signs of damage or degradation. Timely repairs or replacements of worn parts will help maintain optimal performance.

Correct Handling: Handling the tool with care prevents unnecessary strain and potential damage. Follow the recommended guidelines for safe usage to avoid mishandling that could affect the instrument’s functionality.

Proper Storage: Store the equipment in a clean, dry environment to protect it from environmental factors that could cause deterioration. Using designated storage solutions can help maintain the instrument in peak condition.

By adhering to these best practices, you ensure that your tool remains in excellent working order, contributing to its longevity and consistent performance throughout its service life.