In the realm of electronic testing, having a versatile device at your disposal is crucial for accurate diagnostics and measurements. This guide delves into the essentials of using a comprehensive measuring instrument designed to assess various electrical parameters. Whether you are troubleshooting a circuit or verifying component values, mastering this tool can significantly enhance your efficiency and precision.

Explore the core functionalities and operational principles that allow for precise readings in a range of scenarios. With the right knowledge, you’ll be able to leverage this device effectively, ensuring reliable outcomes in your projects. The subsequent sections will walk you through essential procedures, helping you become proficient in handling and interpreting the results from this invaluable equipment.

Equipped with detailed insights and practical advice, this resource is crafted to elevate your expertise. By familiarizing yourself with the various features and techniques, you will gain confidence and skill in measuring electrical properties, ultimately streamlining your diagnostic and testing processes.

Understanding Your Digital Multimeter

In the world of electronic measurement, having a reliable tool for assessing various electrical parameters is crucial. This device provides a range of functions to measure voltage, current, and resistance, making it an indispensable instrument for both professionals and hobbyists. Understanding how to operate and interpret the readings from this device can significantly enhance your efficiency and accuracy in troubleshooting electrical systems.

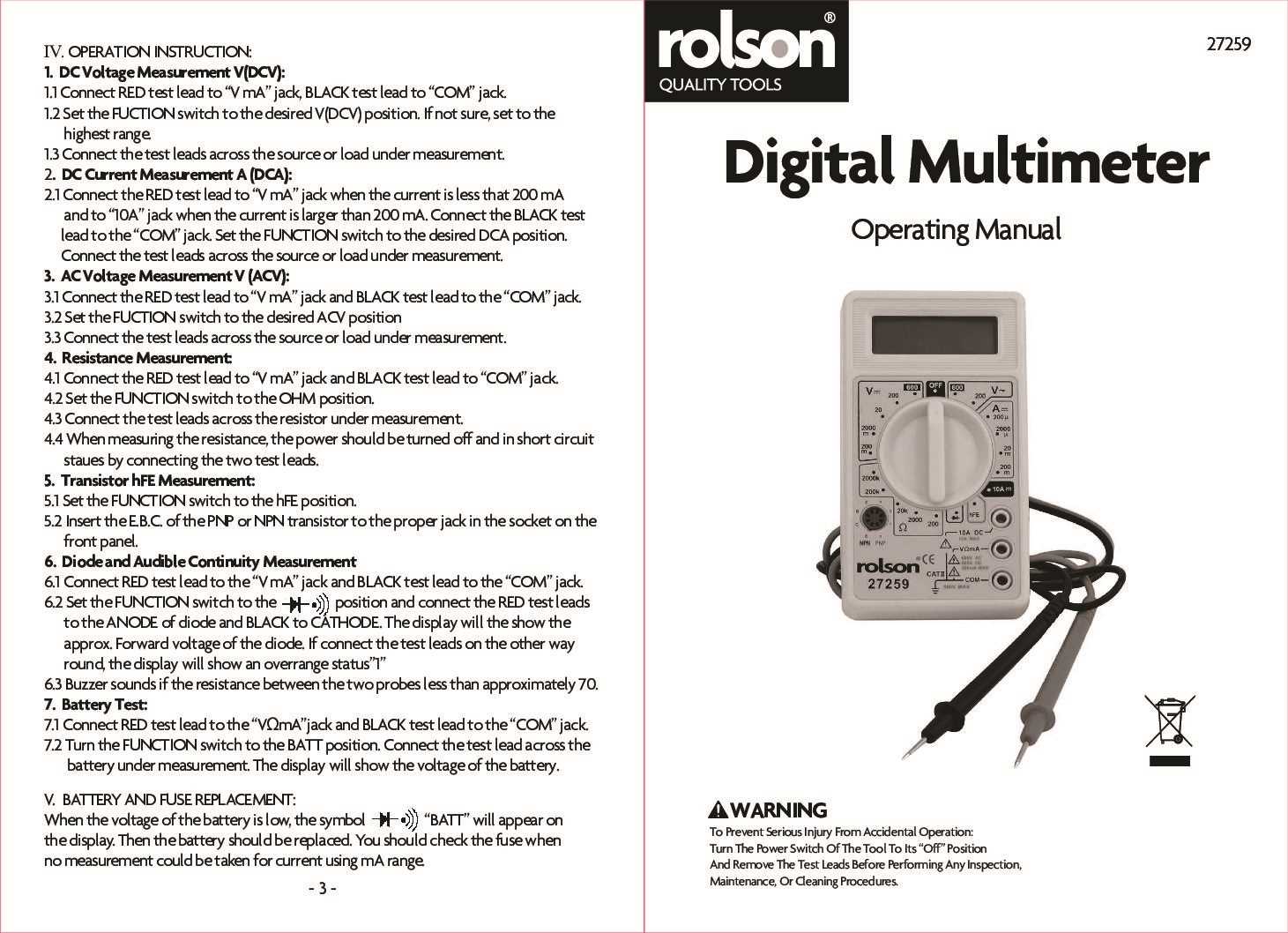

Key Components

To effectively use your device, familiarize yourself with its main parts. Here are the essential components to know:

- Display Screen: Shows the measurement results.

- Selection Knob: Allows you to switch between different measurement modes.

- Probes: Used to connect the device to the circuit or component under test.

- Buttons: Various controls for additional functions, such as range adjustment or data hold.

Basic Operations

Using the device involves a few straightforward steps:

- Choose the Measurement Mode: Turn the selection knob to the desired function, such as voltage, current, or resistance.

- Connect the Probes: Attach the probes to the circuit, ensuring correct polarity for accurate readings.

- Read the Display: Observe the values shown on the screen, which represent the measured parameter.

By understanding these components and procedures, you’ll be better equipped to perform precise measurements and diagnose electrical issues efficiently.

Basic Components and Functions

Understanding the fundamental elements and operations of measuring devices is crucial for effective usage and accurate readings. These instruments typically consist of several core components that work together to perform various measurement tasks. Each part plays a specific role in the process, ensuring that users can obtain precise and reliable data for electrical measurements.

1. Display Screen: This component shows the measurement results. It provides a clear view of the values being measured, allowing users to read and interpret data easily. The display may vary in type, but its primary function is to present information in a readable format.

2. Function Selector: This part allows users to choose the type of measurement they wish to perform, such as voltage, current, or resistance. It enables the instrument to switch between different measurement modes, ensuring versatility and adaptability to various testing scenarios.

3. Probes: These are the conductive tips used to make contact with the electrical circuit or component being tested. They are essential for transferring the electrical signal from the circuit to the device, facilitating accurate measurements.

4. Input Terminals: These ports connect the probes to the measuring device. They ensure that the electrical signal from the probes is properly channeled into the instrument for analysis and display.

5. Measurement Range Selector: This feature allows users to adjust the range of measurement according to the expected value. It helps in achieving accurate readings by scaling the measurement appropriately.

6. Power Source: The device typically operates on batteries or an external power supply. This component is crucial for ensuring that the instrument functions correctly and consistently.

Each of these elements contributes to the overall functionality of the measurement device, enabling it to perform various electrical tests effectively. Familiarity with these components helps users operate the instrument more efficiently and accurately.

Setting Up Your Device Correctly

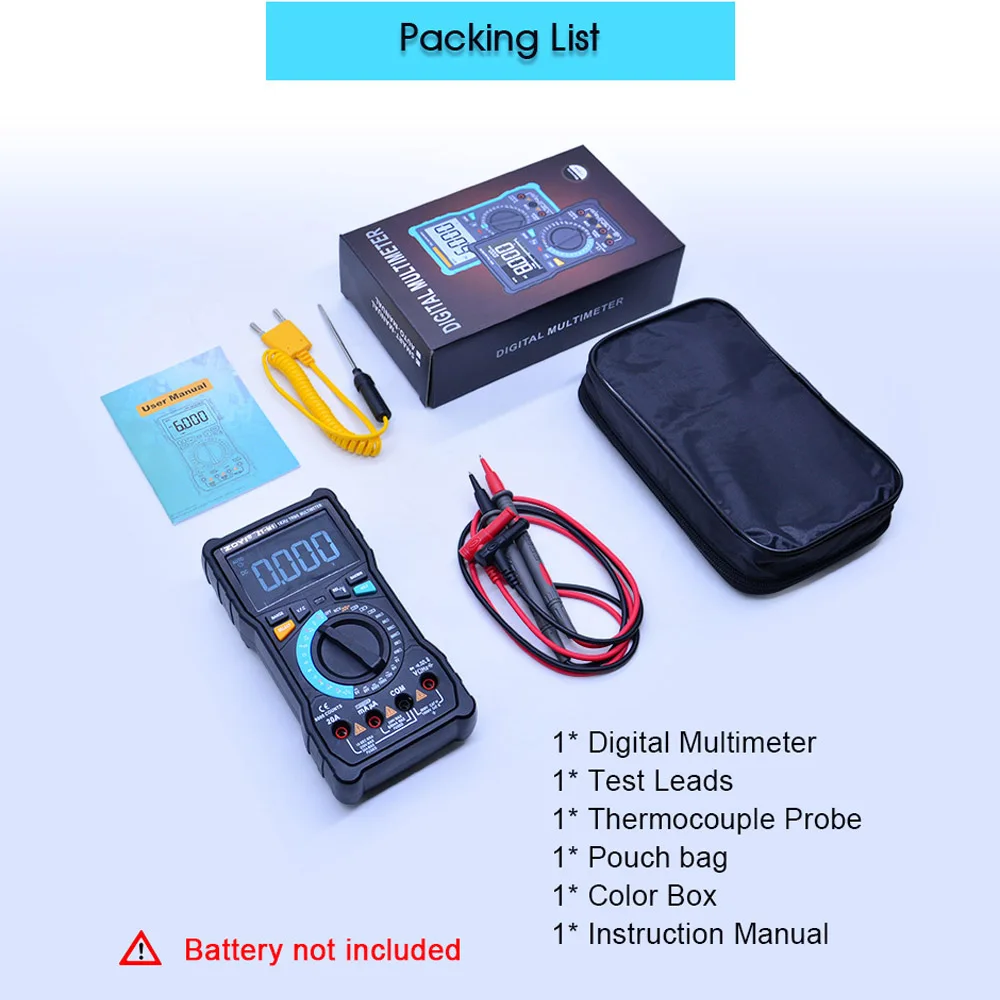

Proper configuration of your measuring instrument is crucial for accurate readings and optimal performance. Ensuring that your device is set up correctly will prevent potential errors and extend its longevity. This section will guide you through the essential steps to get your equipment ready for use.

Initial Preparation

Begin by carefully unpacking the device and inspecting it for any visible damage. Make sure all the necessary components, such as probes and batteries, are included. Refer to the following table for a checklist of initial setup tasks:

| Task | Details |

|---|---|

| Unpack and Inspect | Remove all parts from the packaging and check for physical damage or missing items. |

| Insert Batteries | Open the battery compartment and insert the batteries as indicated by the polarity markings. |

| Connect Probes | Attach the test leads to the correct terminals on the device, ensuring a secure connection. |

| Set Up Display | Adjust the display settings if needed to ensure readability under different lighting conditions. |

Calibration and Testing

Once the initial setup is complete, calibrate your instrument to ensure precise measurements. Follow these steps:

- Turn on the device and select the calibration mode from the menu.

- Follow the on-screen prompts to perform the calibration process.

- After calibration, test the device with a known standard to verify accuracy.

Regular calibration will help maintain accuracy and reliability, making sure your measurements are consistent over time.

Measuring Voltage, Current, and Resistance

Understanding how to accurately gauge electrical parameters is crucial for troubleshooting and assessing circuits. This section delves into the techniques and methods for measuring various electrical quantities, which are essential for diagnosing issues and ensuring proper function.

Voltage measurement is fundamental for checking the potential difference across components. By connecting the probes to two points in a circuit, you can determine if the voltage level is within the expected range. This helps in identifying issues such as power supply problems or faulty connections.

Current measurement involves determining the flow of electric charge through a circuit. To measure current, you need to place the instrument in series with the component being tested. This allows you to monitor the flow and ensure that the current is at the appropriate level, which is vital for assessing circuit performance and safety.

Resistance measurement evaluates how much a component resists the flow of electric current. By measuring resistance, you can check if a component is functioning correctly or if it has become defective. This measurement is done by isolating the component from the circuit and measuring its resistance directly.

Mastering these measurement techniques allows for effective troubleshooting and maintenance of electrical systems, ensuring that all components operate within their specified parameters.

Common Troubleshooting Techniques

When working with electronic measurement devices, encountering issues is not uncommon. Understanding and addressing these problems efficiently can ensure accurate readings and prolong the device’s lifespan. This section outlines key strategies for diagnosing and resolving common problems encountered during device use.

Identifying Display Issues

One frequent issue is a malfunctioning display, which can result in inaccurate or unreadable measurements. If the screen appears blank or shows erratic values, check the following:

| Problem | Possible Cause | Solution |

|---|---|---|

| Blank Screen | Dead battery or loose connection | Replace the battery or ensure connections are secure |

| Erratic Values | Interference or faulty settings | Reduce interference and reset to default settings |

Ensuring Accurate Measurements

Another critical aspect is ensuring that the measurements are accurate and reliable. To address discrepancies in readings:

| Problem | Possible Cause | Solution |

|---|---|---|

| Inconsistent Readings | Improper calibration or incorrect range setting | Recalibrate the device and select the correct measurement range |

| Measurement Error | Faulty probes or connections | Inspect and replace faulty probes or check connections |

Safety Tips for Multimeter Use

Ensuring safety during the use of electrical measuring devices is crucial to prevent accidents and injuries. Proper handling and precautions are essential to avoid potential hazards associated with these tools. Following these guidelines will help you use the equipment safely and effectively.

Handling Precautions

Always verify that the device is in good working condition before use. Inspect the leads and connectors for any damage or wear, and replace them if necessary. Avoid using the equipment in wet or damp environments, and ensure that your hands are dry before handling it.

Measurement Safety

When taking measurements, always start with the highest range setting and work your way down to prevent overloading the device. Never attempt to measure resistance or continuity on a live circuit. Additionally, be cautious when working with high voltage sources and ensure the device is properly rated for the voltage levels you are measuring.

Advanced Features and Their Uses

Modern testing devices offer a range of sophisticated functionalities designed to enhance precision and versatility in measurements. These advanced features are not just supplementary tools but integral components that elevate the device’s performance, making it suitable for a variety of complex tasks.

Advanced Measurement Capabilities

One of the key advancements includes the ability to measure various parameters beyond the basic voltage and current. Features such as capacitance measurement and frequency analysis allow users to handle a wider range of electronic components and circuits. These functionalities enable precise diagnostics and maintenance of electronic systems.

Data Logging and Connectivity

Another significant enhancement is the integration of data logging and communication interfaces. These features facilitate the recording of measurement data over time and its transfer to external devices for detailed analysis. This capability is particularly useful for monitoring long-term trends and conducting comprehensive evaluations of electrical systems.