When working with advanced hydraulic systems, having a comprehensive understanding of the operating principles and maintenance procedures is crucial for ensuring safety and efficiency. This section aims to provide essential guidance for effectively using and maintaining your hydraulic tools, ensuring they operate at their best performance level.

Whether you are new to hydraulic machinery or seeking to refine your knowledge, this resource will offer valuable insights into the correct handling and care of your equipment. By following the outlined procedures and recommendations, you can maximize the lifespan and functionality of your hydraulic tools.

Our goal is to equip you with the necessary information to confidently operate and maintain your hydraulic systems. With detailed explanations and practical tips, you’ll be able to tackle common challenges and perform regular upkeep with ease.

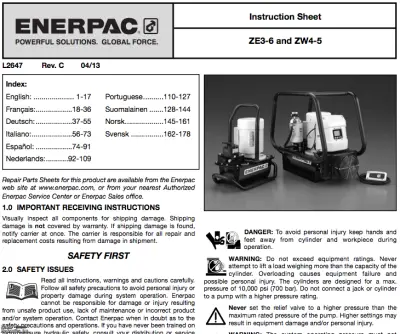

Overview of Enerpac ZU4 Manual

This section provides a comprehensive look at the essential guidelines and operational details associated with the device. It offers insight into the various features, proper usage, and maintenance practices necessary for optimal performance.

Key elements covered include:

- Introduction to the device’s core functions and specifications

- Detailed instructions on safe handling and operation

- Maintenance tips to ensure longevity and efficiency

- Troubleshooting advice for common issues

By following these guidelines, users can maximize the effectiveness and reliability of their equipment, ensuring it meets the highest standards of performance.

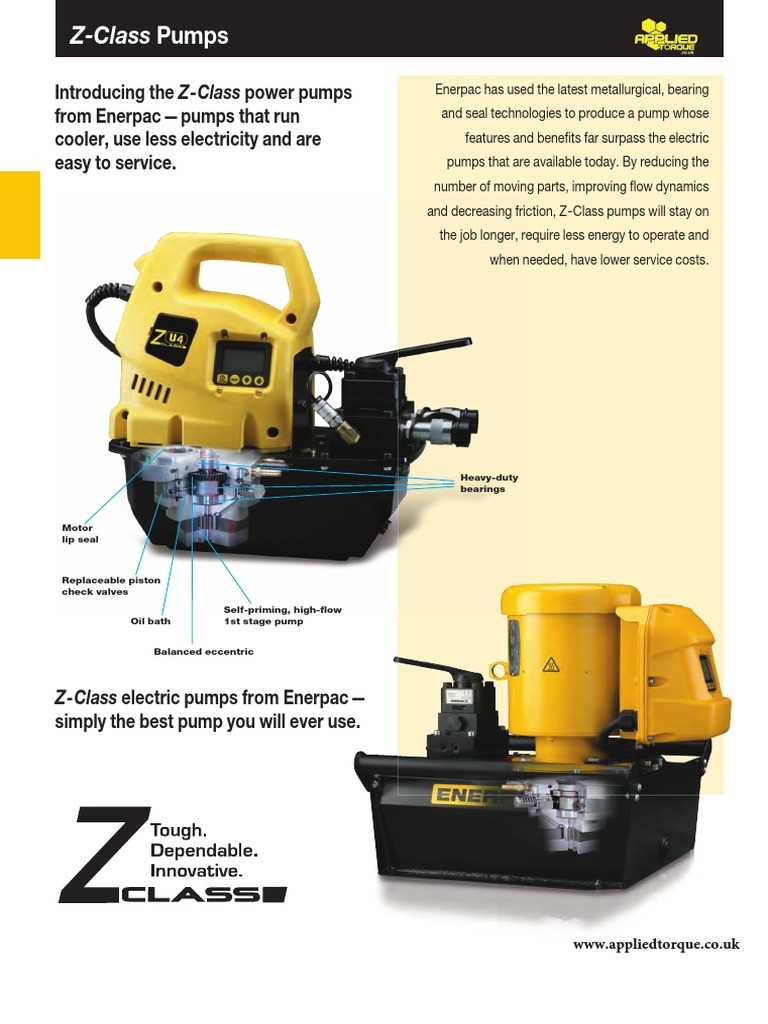

Key Features of the Enerpac ZU4

When selecting hydraulic equipment, understanding its core characteristics is crucial for ensuring it meets your specific needs. This section highlights the principal attributes of this powerful tool, emphasizing its capabilities and advantages. Here, we break down its essential components and functionalities, providing insights into how it stands out in its category.

| Feature | Description |

|---|---|

| High Pressure Capacity | Designed to handle significant pressure levels, making it suitable for demanding tasks. |

| Durable Construction | Constructed from robust materials to ensure longevity and withstand rigorous use. |

| Precision Control | Offers precise control over hydraulic functions, enhancing accuracy in operations. |

| Ease of Use | Features an intuitive design that simplifies operation and reduces the learning curve. |

| Compact Design | Its compact size allows for easier handling and storage, even in confined spaces. |

Step-by-Step Operating Instructions

To ensure safe and effective use of the equipment, it is crucial to follow a systematic approach. This guide provides a comprehensive sequence of actions required to operate the device correctly. Each phase of the process is outlined to help users achieve optimal performance and avoid common pitfalls.

Begin by carefully reading through the setup procedures to familiarize yourself with the necessary preparations. This initial step ensures that you understand the equipment’s configuration and any prerequisites needed before starting the operation.

Next, proceed to the operational phase by executing the outlined steps. This involves activating the controls in a specific order and monitoring the device’s responses to ensure it functions as intended. Pay close attention to any indicators or feedback from the equipment to confirm that it is operating within the desired parameters.

Finally, follow the shutdown and maintenance instructions to properly conclude the operation. This includes safely deactivating the equipment and performing any required cleaning or inspections to maintain its condition and readiness for future use.

Safety Precautions and Guidelines

When handling hydraulic equipment, it is crucial to adhere to specific safety measures to ensure both personal protection and the proper functioning of the tools. Following these precautions will help minimize risks associated with the use of such machinery and maintain a safe working environment.

1. Always read the provided documentation thoroughly before operating the equipment. Understanding the operational procedures and safety warnings is essential for safe usage.

2. Wear appropriate personal protective equipment (PPE) including safety glasses, gloves, and protective clothing. This helps to guard against potential hazards such as high-pressure fluid leaks or accidental equipment malfunctions.

3. Ensure that the equipment is in good working condition before use. Regularly inspect the machinery for any signs of wear, damage, or malfunction. Address any issues immediately by performing necessary repairs or replacements.

4. Follow proper setup and operation procedures as outlined in the documentation. Incorrect setup or handling can lead to accidents or damage. Make sure that all connections are secure and that the equipment is correctly positioned before use.

5. Keep the work area clean and free of obstructions. A clutter-free environment reduces the risk of tripping hazards and ensures that you can move around the equipment safely.

6. Be aware of your surroundings and potential hazards. Avoid operating the equipment in hazardous environments or near other people who may inadvertently come into contact with moving parts or pressurized components.

7. Follow emergency procedures in case of a malfunction or accident. Know how to quickly shut down the equipment and seek help if necessary.

8. Store the equipment properly when not in use. Ensure that it is kept in a dry, secure location to prevent unauthorized access and to protect it from environmental damage.

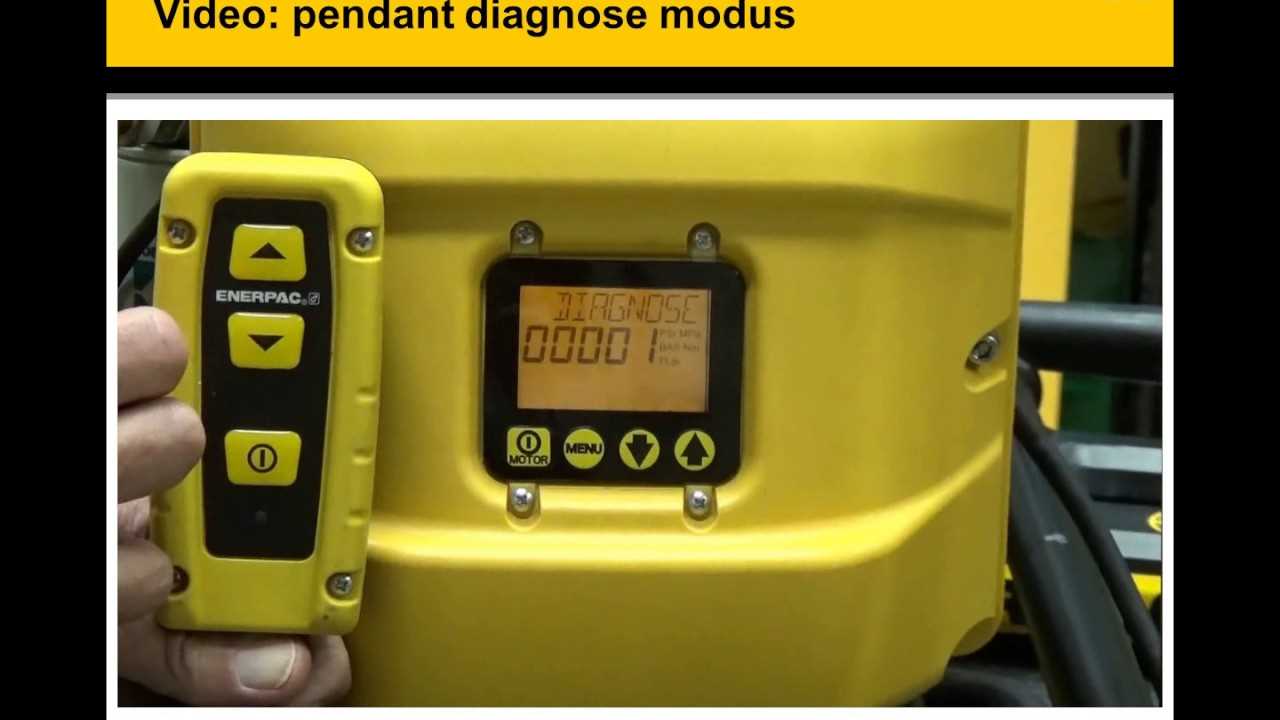

Troubleshooting Common Issues

When dealing with hydraulic equipment, encountering problems is not uncommon. Understanding how to identify and address these issues efficiently can save time and prevent costly repairs. This section aims to guide you through resolving frequent complications that may arise during operation.

Device Fails to Operate

- Check power source connections.

- Ensure that all control settings are correctly adjusted.

- Inspect for any visible damage or wear on components.

- Verify that hydraulic fluid levels are adequate.

Erratic Performance

- Examine hydraulic fluid for contamination or air bubbles.

- Ensure all hoses and connections are secure and leak-free.

- Check if any filters need cleaning or replacement.

- Assess the condition of the control valves for proper operation.

Maintenance Tips for Longevity

Proper upkeep is crucial for extending the lifespan and ensuring optimal performance of your equipment. Regular maintenance not only helps prevent unexpected failures but also promotes safety and efficiency. Here are some essential practices to keep your equipment in top condition:

Routine Checks

- Inspect the device regularly for signs of wear and tear. Look for any loose components, leaks, or unusual noises.

- Ensure that all connections are secure and that there are no signs of corrosion or damage.

- Verify that the equipment is operating within its recommended parameters to prevent overloading.

Cleaning and Lubrication

- Keep the equipment clean by removing dust, dirt, and debris. Use appropriate cleaning agents that do not damage the components.

- Apply lubricants as specified in the manufacturer’s guidelines to reduce friction and wear on moving parts.

- Regularly check and replace filters or other consumables as needed to maintain efficient operation.

Contact Information for Support

If you require assistance or have questions regarding your equipment, it’s important to know where to find reliable support. This section provides guidance on how to reach out for help and ensures you get the answers you need in a timely manner.

Customer Service

For immediate support and general inquiries, contact our customer service team. They are available to assist with troubleshooting, technical questions, and product information. You can reach them through the following methods:

- Phone: [Customer Service Phone Number]

- Email: [Customer Service Email Address]

- Website: [Customer Service Website URL]

Technical Support

For more specialized help, particularly with technical issues or detailed product problems, contact our technical support team. They offer in-depth assistance and can provide solutions tailored to specific concerns. Use the following contact details:

- Phone: [Technical Support Phone Number]

- Email: [Technical Support Email Address]

- Website: [Technical Support Website URL]

Ensuring you have the right contact information helps streamline your support experience and resolves issues more efficiently.