Exploring vintage textile apparatus reveals a wealth of historical craftsmanship and engineering. Such devices, cherished for their precision and durability, offer a unique glimpse into past technological advancements. Understanding these tools involves delving into their operational details and maintenance practices, crucial for preserving their functionality and longevity.

Whether you’re a collector, a hobbyist, or simply curious about the evolution of textile technology, this guide provides essential insights. Learn about the intricate mechanisms and adjustments that define these classic tools. Mastering their use not only enhances appreciation but also ensures they continue to serve their purpose effectively.

History of Singer Sewing Machines

The evolution of one renowned brand in the textile industry represents a significant chapter in the advancement of home and industrial stitching technologies. This company has played a pivotal role in shaping the way garments are created and repaired.

- Early Innovations: Founded in the mid-19th century, the company introduced revolutionary mechanisms that transformed textile production.

- Technological Advancements: Throughout the decades, continuous improvements were made to enhance functionality, including the introduction of various models designed to meet diverse needs.

- Global Impact: The reach of this brand extended worldwide, influencing both domestic and commercial stitching practices across different cultures and regions.

Examining the progression of this brand provides insight into its impact on modern textile technologies and highlights its enduring legacy in the industry.

Evolution of Sewing Techniques

The development of stitching methods has transformed significantly over time, reflecting advancements in technology and changes in societal needs. From handcrafts to mechanized processes, each era has contributed to refining and enhancing textile creation techniques.

Early Handcraft Techniques

Initially, stitching was performed manually, relying on basic tools and techniques. This era was characterized by:

- Simple needle and thread use

- Basic stitching patterns

- Handcrafted embellishments and repairs

Mechanized Innovations

With the advent of mechanization, new methods emerged, introducing efficiency and precision:

- Introduction of mechanized stitching devices

- Standardization of stitching patterns

- Enhanced speed and accuracy

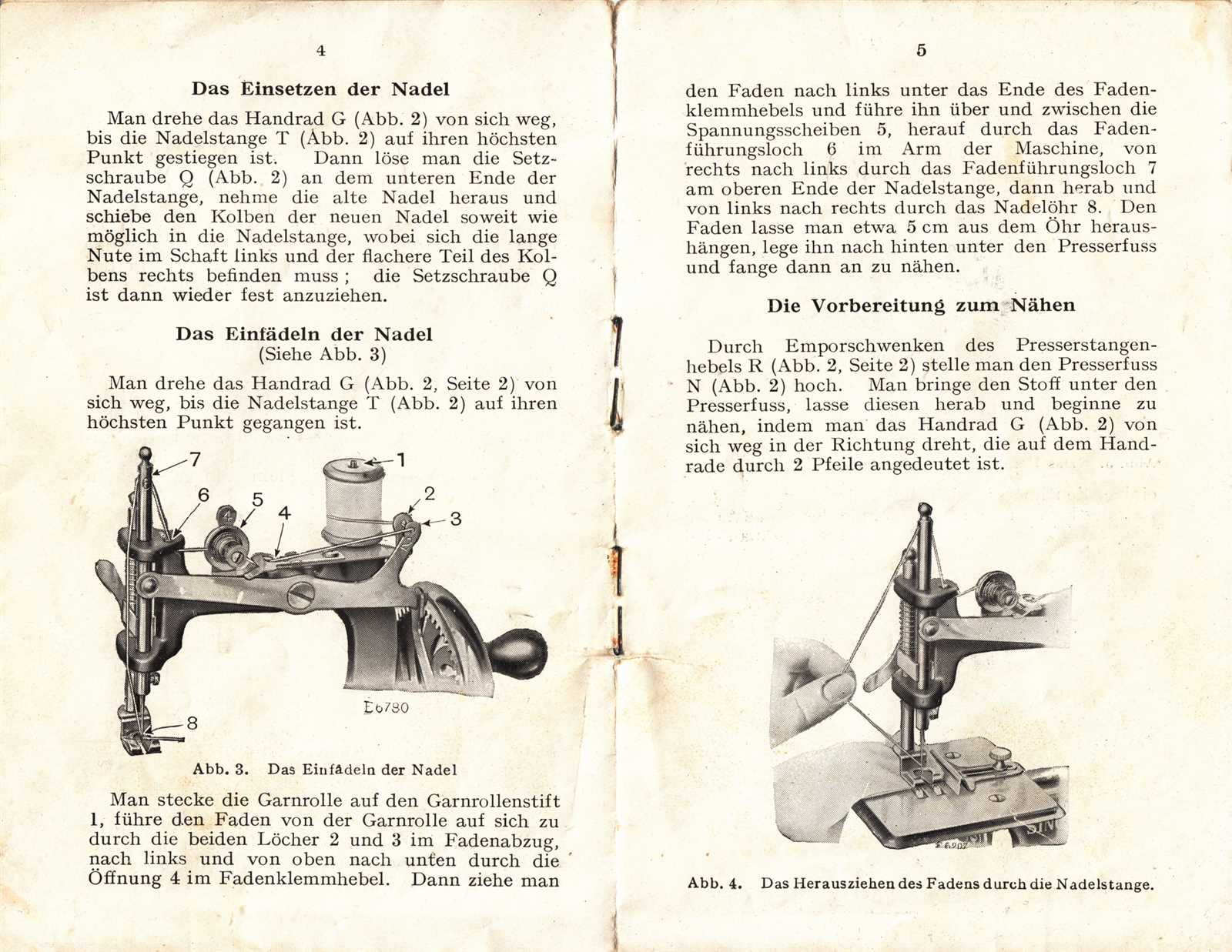

Understanding Machine Components

Grasping the essential elements of a vintage stitching device is crucial for both operation and maintenance. Each part plays a specific role in ensuring smooth performance and longevity. This section delves into the various segments that make up these intricate systems, aiming to provide a clear overview for users and enthusiasts alike.

Core Elements

- Needle Holder: Secures the needle in place for accurate stitching.

- Feed Mechanism: Moves the fabric through the device, facilitating the stitching process.

- Thread Tension Control: Regulates the tightness of the thread to ensure consistent stitching quality.

Auxiliary Components

- Bobbin Case: Holds the bobbin, which provides the lower thread needed for stitching.

- Presser Foot: Presses the fabric against the feed mechanism to maintain proper alignment.

- Stitch Selector: Allows users to choose different stitch patterns and functions.

Key Features of Vintage Models

Antique fabric crafting devices are celebrated for their timeless craftsmanship, distinctive details, and durable construction. These classic apparatuses reflect a period when intricate engineering and elegant designs were prioritized, making them stand out from their modern counterparts. In this section, we’ll explore some of the unique aspects that define these collectible pieces.

Durable Construction

One of the standout characteristics is their robust build quality. Many were constructed with metal components, which contribute to their longevity and resilience. Unlike contemporary models that may rely on plastic, these heritage designs often feature cast iron or steel, ensuring they can withstand years of use with minimal wear.

Ornate Designs and Details

Another defining feature is their ornate aesthetic. These models often showcase decorative elements such as detailed engravings, hand-painted motifs, and distinctive logos. Such artistry not only served a functional purpose but also added a touch of elegance, making each device a work of art in its own right.

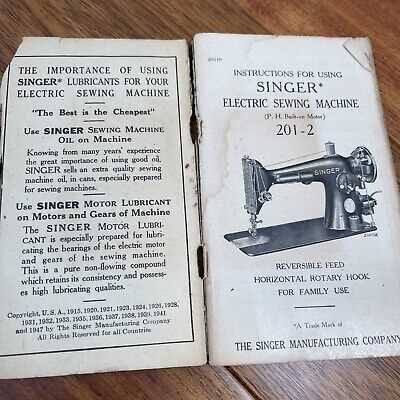

Maintenance Tips for Old Machines

Ensuring the longevity of vintage equipment requires a consistent maintenance routine. Regular care not only preserves functionality but also enhances performance, making your apparatus more reliable over time.

- Regular Cleaning: Dust and debris can affect performance. Clean the equipment regularly with a soft, dry cloth and avoid using harsh chemicals.

- Lubrication: Apply a suitable lubricant to moving parts to prevent wear and ensure smooth operation. Follow the manufacturer’s recommendations for the type of lubricant to use.

- Check for Wear: Inspect parts for signs of wear or damage. Replace any worn components promptly to avoid further issues.

- Proper Storage: Store the equipment in a dry, dust-free environment to prevent rust and other damage. Use protective covers if available.

- Regular Servicing: Schedule professional servicing periodically to address any underlying issues and maintain optimal performance.

Common Troubleshooting Issues

When working with classic textile tools, users often encounter various issues that may hinder smooth operation. Understanding these common problems and their solutions can significantly enhance the efficiency and longevity of your equipment.

Thread Tension Problems

Inconsistent thread tension is a frequent issue. This can lead to uneven stitching or thread breakage. Ensure that both the upper and lower thread tensions are correctly adjusted and check that the threads are properly threaded through their respective guides.

Needle Issues

Another common problem involves the needle. Issues such as bent or dull needles can cause irregular stitching patterns. Regularly inspect the needle for any signs of wear or damage and replace it as needed to maintain optimal performance.