Understanding the operation and care of your new spraying equipment is crucial for achieving optimal performance and extending its lifespan. This guide provides essential information to help you navigate the features and functionalities of your device. Whether you are a seasoned professional or a DIY enthusiast, mastering these basics will ensure that your tasks are completed efficiently and effectively.

From setup and usage to maintenance and troubleshooting, this document covers all the necessary steps for making the most out of your spraying apparatus. By following these instructions, you will be able to handle various projects with ease, ensuring that you achieve the best possible results every time.

Explore the comprehensive details provided here to familiarize yourself with the best practices and techniques. Proper understanding and application of these guidelines will not only enhance your overall experience but also ensure the longevity of your equipment.

This section provides a comprehensive introduction to a versatile tool designed for efficient application of various coatings and treatments. The device is engineered to streamline the process of covering large surfaces with ease, making it a valuable asset for both professional and DIY projects. Understanding its core features and functionalities is essential for maximizing its potential and achieving optimal results.

Key Features

- Efficient application mechanism for even coating

- Adjustable settings for different tasks

- High capacity for extended use

- Ergonomic design for user comfort

Benefits

- Saves time and effort compared to traditional methods

- Provides a smooth and consistent finish

- Reduces material waste

- Suitable for a range of substances and surfaces

Features and Specifications

This section provides an overview of the key attributes and technical details of the device designed for efficient coating application. Understanding these features helps users make informed decisions and ensures optimal usage of the equipment.

| Feature | Description |

|---|---|

| Application Rate | Adjustable settings to control the amount of liquid applied per unit area. |

| Tank Capacity | Large reservoir designed to hold ample amounts of coating material for extended use. |

| Power Source | Utilizes an electrical connection to drive the application process, ensuring consistent performance. |

| Flow Adjustment | Features a variable flow control to tailor the output to specific needs. |

| Durability | Constructed from robust materials to withstand frequent usage and challenging conditions. |

| Ease of Maintenance | Designed for straightforward cleaning and maintenance to ensure longevity and reliability. |

Getting Started with Your Sprayer

Before you begin using your new device, it’s essential to familiarize yourself with its basic functions and setup procedures. This guide will help you get acquainted with the equipment and ensure you use it effectively for your projects. Follow these initial steps to prepare your device for optimal performance.

Start by reviewing all the components included in the package. Make sure everything is present and in good condition. Assemble the parts according to the provided guidelines, ensuring all connections are secure and properly aligned. Once assembled, it’s important to understand how to operate the device, including how to adjust settings for different tasks.

For safety, always wear appropriate protective gear and work in a well-ventilated area. Before applying any material, test the device on a small, inconspicuous area to ensure it functions correctly and produces the desired results. Regular maintenance and proper cleaning will keep your equipment in excellent condition and extend its lifespan.

Application Techniques and Tips

Effective application of coatings requires understanding the best methods and practices to achieve a smooth and even finish. Whether you’re working on a small project or a large surface, using the right techniques can make a significant difference in the quality of the outcome.

- Preparation: Always ensure that the surface is clean, dry, and free of any debris or previous coatings that might interfere with adhesion. Sanding the surface can help create a better grip for the new layer.

- Technique: Hold the tool at a consistent distance from the surface, typically 6 to 12 inches, to ensure an even application. Move the tool in a steady, overlapping motion to avoid streaks and uneven coverage.

- Consistency: Maintain a consistent speed and pressure to prevent drips and runs. It’s important to apply a thin, even layer rather than overloading the surface with too much material at once.

- Environmental Conditions: Be mindful of the weather conditions, such as humidity and temperature, as they can affect the drying time and overall finish. Aim to work in moderate temperatures and avoid high humidity levels for the best results.

- Cleanup: Clean the equipment thoroughly after use to prevent clogs and maintain its performance. Follow the manufacturer’s guidelines for proper cleaning procedures to extend the lifespan of the tool.

Maintenance and Care Guidelines

Proper upkeep and attention are essential for ensuring the longevity and optimal performance of your device. Regular maintenance helps to prevent issues and ensures that your equipment operates smoothly and efficiently. This section provides key practices and recommendations to keep your tool in top condition.

- Cleaning: Regularly clean all components of the device to remove any residue or build-up. Use appropriate cleaning agents and follow the manufacturer’s recommendations for cleaning procedures.

- Inspection: Periodically inspect the equipment for any signs of wear or damage. Check for loose or malfunctioning parts and replace them as needed to prevent further issues.

- Lubrication: Apply lubrication to moving parts as specified in the guidelines. Proper lubrication reduces friction and prevents premature wear and tear.

- Storage: Store the equipment in a dry and safe place when not in use. Ensure that it is protected from extreme temperatures and environmental factors that could cause damage.

- Usage: Follow recommended usage practices to avoid overuse or misuse. Adhere to any operational limits and avoid pushing the device beyond its designed capacity.

By following these maintenance and care practices, you can extend the life of your equipment and ensure it performs reliably when needed.

Common Issues and Troubleshooting

When using a device designed for applying coatings, you might encounter various challenges. Understanding how to address these common problems can help ensure smooth operation and achieve optimal results. This section outlines frequent issues users face and provides solutions to rectify them.

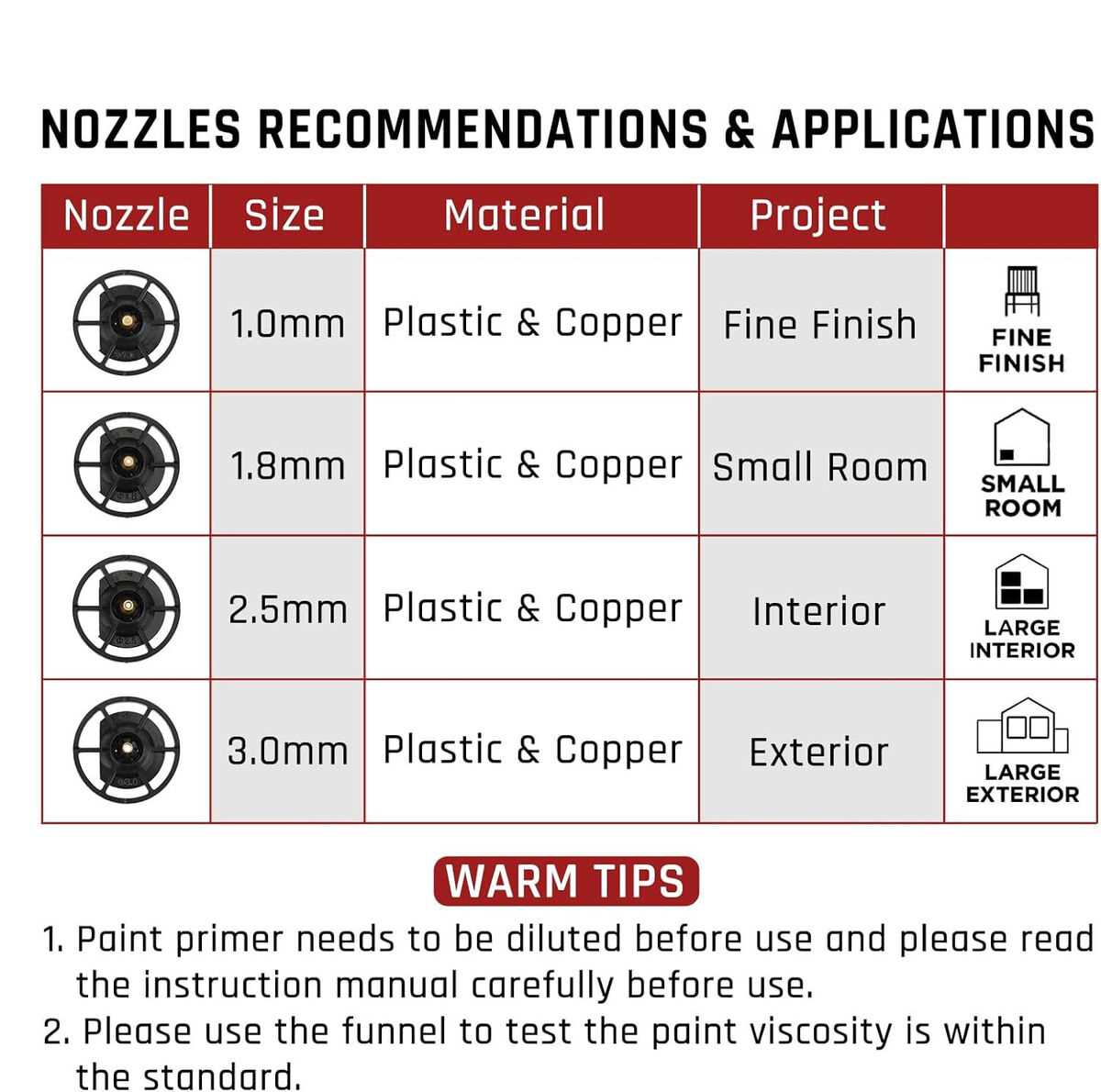

Inconsistent Spray Patterns: If you notice uneven application, check the nozzle for clogs or blockages. Cleaning the nozzle thoroughly can often resolve this issue. Additionally, ensure that the device is set to the appropriate mode for the task.

Low Pressure or Weak Output: A common problem is reduced pressure, which can be caused by an inadequate power source or air leaks in the system. Verify that the power supply is sufficient and inspect all connections for leaks.

Device Not Starting: If the unit fails to turn on, confirm that it is correctly plugged in and that the power switch is in the ‘on’ position. Additionally, check the circuit breaker or fuse to ensure that there is no electrical issue.

Excessive Noise: Unusual noise during operation may indicate internal issues or improper assembly. Ensure that all components are securely attached and refer to the maintenance guidelines for any required adjustments.

By addressing these typical issues, users can maintain their equipment’s performance and longevity. Regular maintenance and prompt troubleshooting can significantly enhance the efficiency of your coating applications.

Safety Precautions and Best Practices

When using high-performance spraying equipment, it’s essential to follow safety guidelines and best practices to ensure both effective operation and personal safety. Proper handling and maintenance can prevent accidents and prolong the lifespan of the equipment.

- Read the Documentation: Always start by thoroughly reading the user documentation provided with the equipment. Understanding the manufacturer’s instructions is crucial for safe operation.

- Wear Appropriate Safety Gear: Equip yourself with suitable safety gear such as gloves, goggles, and a mask to protect against potential hazards.

- Ensure Proper Ventilation: Use the equipment in well-ventilated areas to avoid inhaling harmful fumes and to maintain a safe working environment.

- Check for Leaks: Regularly inspect the equipment for any leaks or damage before use. Address any issues immediately to prevent accidents.

- Use the Correct Materials: Only use materials and chemicals recommended by the manufacturer to avoid equipment damage and ensure optimal performance.

- Maintain Cleanliness: Keep the equipment clean and well-maintained to ensure efficient operation and to prevent the buildup of residues that could cause malfunctions.

- Follow Electrical Safety: Ensure all electrical connections are secure and dry. Avoid using the equipment in wet conditions to prevent electrical hazards.

- Store Properly: After use, store the equipment in a dry, cool place to protect it from environmental damage and prolong its service life.