In today’s fast-paced world, ensuring accurate measurement of rotational speed is crucial for many professionals and enthusiasts. Understanding how to properly utilize a digital device that measures revolutions can enhance both performance and precision in various fields. Whether you’re a seasoned mechanic or an avid hobbyist, knowing how to interpret and utilize these readings effectively can make all the difference.

This guide will walk you through the key steps needed to get the most out of your equipment. By following the outlined procedures, you’ll be able to achieve precise results, avoid common mistakes, and ensure your measurements are reliable and consistent. Additionally, we will explore the essential features of this device and provide useful tips for maintaining its accuracy and longevity.

Through these insights, you’ll not only become proficient in handling your device but also gain confidence in using it across different applications. Embracing these techniques will empower you to maximize your tool’s potential, contributing to greater efficiency and success in your projects.

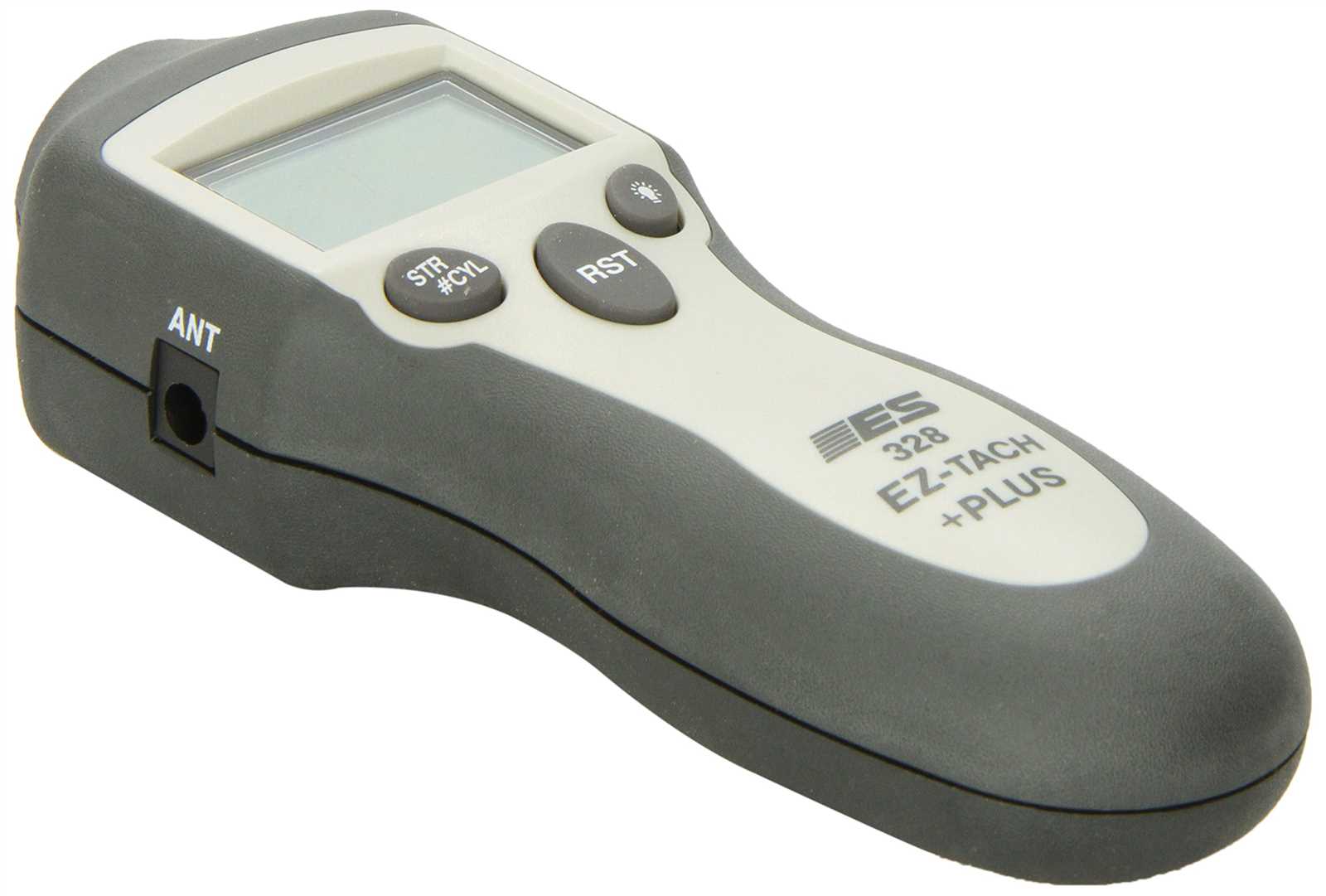

Es 328 Tachometer Instruction Manual

This section provides an overview of a sophisticated device designed for accurately measuring rotational speed. The equipment is renowned for its precision and reliability, making it an essential tool for various applications.

Key Features

- High precision and accuracy in capturing rotational measurements.

- Durable design, suitable for both professional and personal use.

- Easy to operate with intuitive controls.

Usage Guidelines

- Ensure the device is properly calibrated before use.

- Position the sensor correctly to avoid any interference during measurements.

- Regularly maintain the equipment to guarantee long-term accuracy and performance.

Understanding the Es 328 Tachometer Functions

Grasping the capabilities and features of this device is crucial for optimizing its use. By familiarizing yourself with the various functionalities it offers, you can ensure accurate readings and efficient performance. This section delves into the essential aspects you need to comprehend.

- Measurement Modes: The device provides multiple modes for different types of measurements, ensuring flexibility in various scenarios.

- Display Options: Users can customize the display to suit their preferences, allowing for clearer and more accessible data interpretation.

- Data Recording: The ability to store and review data ensures that critical information is not lost and can be analyzed later.

- Maintenance Alerts: Regular notifications help in maintaining the device, ensuring it remains in optimal working condition over time.

Setting Up the Es 328 Tachometer

Properly configuring your device is essential to ensure accurate measurements and optimal performance. This section will guide you through the process of preparing your tool for use, covering essential steps to connect, calibrate, and customize the settings according to your needs.

Initial Connections

Begin by establishing the necessary connections. Ensure that all cables are securely attached, and the power source is stable. Carefully follow the wiring diagram to connect the system to the monitoring equipment. Double-check each connection to prevent any errors that might affect the functionality.

Calibration Process

Once all connections are in place, proceed to calibrate the device. Calibration is crucial for achieving precise readings. Follow the instructions to set the correct parameters. The table below outlines the key calibration settings and their respective values.

| Parameter | Recommended Value |

|---|---|

| Input Sensitivity | 0.5 V |

| Output Range | 10 – 500 Hz |

| Pulse Frequency | 50 Hz |

After calibration, review the settings to confirm accuracy, and make any necessary adjustments. Your device is now ready for operation.

How to Calibrate the Gauge

Ensuring the accuracy of your measurement device is essential for optimal performance. Proper calibration involves adjusting the device to match a known reference point, ensuring that the readings are precise and reliable. This process requires careful attention to detail and following the correct steps to align the device’s settings with the desired parameters.

| Step | Action |

|---|---|

| 1 | Begin by turning off the engine and disconnecting the power source. This step ensures safety and prevents any accidental readings during the calibration process. |

| 2 | Connect the calibration tool to the device. This tool will serve as the reference point, providing the necessary data to adjust the settings accurately. |

| 3 | Follow the instructions provided by the calibration tool manufacturer to align the settings of your device with the reference data. Ensure that all adjustments are made precisely as instructed. |

| 4 | Once the settings are adjusted, reconnect the power source and restart the engine. Monitor the readings to confirm that the device now displays accurate measurements. |

| 5 | If necessary, repeat the calibration process until the device provides consistent and accurate data. Once satisfied, document the calibration process and store the calibration tool for future use. |

Interpreting Tachometer Readings Accurately

Understanding how to read and interpret the measurements from your speed monitoring device is crucial for accurate performance assessment and maintenance. Proper interpretation ensures that you can effectively monitor engine or motor operations, making adjustments as necessary to maintain optimal functioning.

Key Considerations for Accurate Readings

- Calibration: Ensure that the device is correctly calibrated before taking any readings. An improperly calibrated gauge can provide misleading information, leading to incorrect conclusions.

- Unit of Measurement: Be aware of the units used by your device. Different units can affect the interpretation of the readings, so verify that you are using the correct unit for your specific needs.

- Environmental Factors: Consider environmental conditions that may impact the accuracy of the readings, such as temperature fluctuations and vibrations. These factors can influence the performance and reliability of the device.

- Reading Consistency: Take multiple readings and average them to ensure accuracy. Single readings can sometimes be anomalous, so a series of measurements will provide a more reliable assessment.

Common Misinterpretations and How to Avoid Them

- Overlooking Calibration Issues: Regularly check and adjust the calibration to avoid erroneous readings. Neglecting calibration can lead to persistent inaccuracies.

- Ignoring Unit Conversion: When comparing readings from different devices or systems, ensure you convert units appropriately to avoid misinterpretation.

- Misreading Environmental Impact: Be mindful of how external conditions might skew readings. Account for these factors to ensure that your data remains reliable.

- Relying on Single Measurements: Avoid making conclusions based on a single reading. Multiple measurements will help verify the accuracy of your data and provide a more comprehensive understanding.

Troubleshooting Common Tachometer Issues

When dealing with measurement devices, it’s crucial to address any issues that might arise to ensure accurate performance. Below are some common problems encountered and their solutions.

- Inaccurate Readings:

If the device provides readings that seem incorrect, consider recalibrating it. Ensure the calibration settings are correct according to the specifications. Verify that the input signals are accurate and consistent.

- Display Problems:

Should the display fail to show any readings or show garbled information, check the connections and wiring. Inspect the display for any visible damage and ensure that the device is powered on properly.

- Device Not Responding:

If the device does not respond to controls or adjustments, restart it and check the power supply. Ensure that all buttons and switches are functioning and that there are no loose connections.

- Erratic Behavior:

When the device shows fluctuating or erratic readings, it might be affected by electrical interference. Check for any sources of interference nearby and ensure proper grounding of the equipment.

By systematically addressing these issues, you can maintain optimal performance and reliability of your measurement device.

Maintaining Your Es 328 Tachometer

Proper upkeep is crucial for ensuring the longevity and accurate performance of your measurement device. Regular maintenance helps in avoiding malfunctions and extends the operational life of the equipment.

Routine Checks

Perform periodic inspections to detect any signs of wear or damage. Check the connections and cables for signs of fraying or corrosion. Ensure that the device is free from dust and debris that could affect its performance.

Calibration and Accuracy

To maintain precise readings, regularly calibrate the equipment according to the manufacturer’s guidelines. This ensures that the device continues to provide accurate and reliable measurements over time.