The process of creating precise openings in various materials is a task that requires both accuracy and the right equipment. Whether you’re working with leather, fabric, or metal, having a reliable tool can make all the difference in achieving professional results. This guide aims to provide a clear understanding of how to effectively operate a device designed for this purpose, ensuring that each use yields consistent and accurate outcomes.

Proper handling and technique are crucial for the successful use of any equipment. With this guide, you’ll learn the essential steps to prepare, adjust, and utilize your tool for making clean and precise holes. By following these guidelines, even those new to the process can master it quickly, while experienced users will find valuable tips for refining their technique.

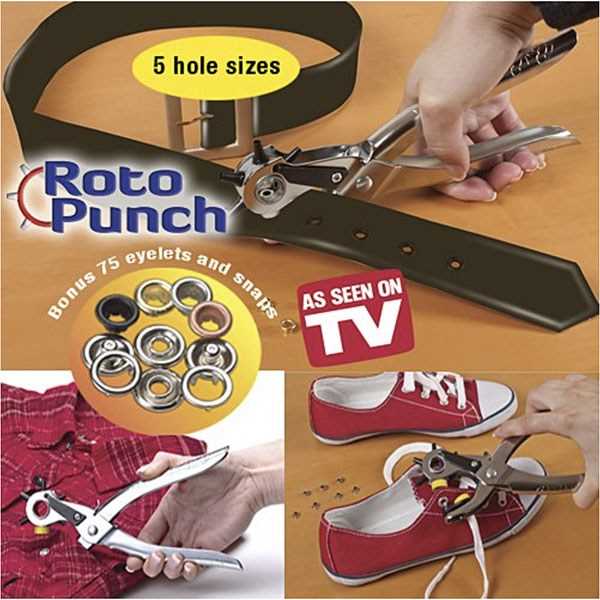

Understanding the Tool’s Components and their functions is key to maximizing its potential. This guide will walk you through each part, explaining how to make the most of the tool’s adjustable features. From selecting the right size to ensuring a clean cut, every aspect is covered to help you achieve the best possible results with minimal effort.

Using the Roto Punch Tool Safely

When working with any handheld device, prioritizing safety is essential to prevent accidents and ensure efficient results. Following a few key guidelines will help you operate the tool effectively while minimizing the risk of injury.

- Wear Protective Gear: Always use appropriate safety gear, such as gloves and eye protection, to guard against unexpected slips or material fragments.

- Secure the Material: Ensure the item you are working on is firmly held in place. A stable working surface reduces the chance of mistakes or mishaps.

- Use Proper Force: Apply consistent and controlled pressure when operating the tool. Avoid excessive force, which could lead to damage to both the tool and the material.

- Maintain the Tool: Regularly inspect the device for any wear or damage. Keeping it in good condition helps prevent malfunctions during use.

- Store Safely: After use, store the tool in a safe, dry location, away from children’s reach and other tools that could cause damage.

By adhering to these practices, you can ensure that your projects are completed safely and efficiently, without unnecessary risks.

Benefits of a Roto Punch for Crafting

Creating handmade items often requires precision and versatility. A versatile crafting tool can be an essential asset in ensuring clean cuts, accurate sizing, and overall efficiency in the creation process. Whether working with leather, fabric, or other materials, having a multi-functional tool can simplify and enhance the crafting experience.

Enhanced Precision and Control

One of the primary advantages of using a specialized tool in crafting is the ability to achieve high levels of precision. The tool allows for the creation of perfectly sized holes, which is crucial when working on detailed projects. This level of control helps in maintaining the integrity of the material and ensures that the final product meets the desired specifications.

Versatility in Applications

The tool is designed to be adaptable to various crafting needs, making it suitable for a wide range of materials and projects. From adjusting the size of the holes to working with different material types, this tool provides flexibility that can save time and reduce the need for multiple devices.

- Works with various materials including leather, fabric, and plastic

- Adjustable for different sizes, ensuring custom-fit results

- Streamlines the crafting process by reducing the need for additional tools

In summary, this multi-functional crafting tool offers significant benefits by enhancing precision, control, and versatility, making it an invaluable addition to any craftsperson’s toolkit.

Choosing the Right Punch Size

Selecting the appropriate tool size is crucial for achieving the best results in your projects. The correct dimensions of the implement can significantly impact the quality and precision of the work. Whether you’re working with materials like paper, fabric, or plastic, the size of the tool should match your specific requirements to ensure a clean and accurate outcome.

Understanding Your Needs

First, consider the purpose of the task at hand. Are you creating small, intricate designs or larger, more substantial cuts? The size of the tool will determine the scale and detail you can achieve. For delicate tasks, a smaller size is often preferred, while larger sizes are better suited for more robust applications.

Material Considerations

Different materials may require different sizes of tools for optimal results. For instance, thicker materials might need a larger tool to ensure clean and precise cuts, while thinner materials can be handled with a more compact option. Assessing the material you will be working with will guide you in selecting the most suitable tool size.

Maintenance Tips for Longevity

Proper upkeep of your equipment is essential for ensuring its extended lifespan and consistent performance. By following a few key practices, you can prevent common issues and maintain the optimal functionality of your device.

Regular Cleaning: It is crucial to keep all components free from dust and debris. Regularly wipe down surfaces with a soft, dry cloth and use compressed air to remove particles from hard-to-reach areas. Avoid using harsh chemicals that could damage sensitive parts.

Inspection and Lubrication: Periodically inspect moving parts for wear and tear. Apply suitable lubricants to prevent friction and ensure smooth operation. Be sure to use lubricants recommended by the manufacturer to avoid any potential damage.

Proper Storage: When not in use, store your device in a clean, dry environment. Protect it from extreme temperatures and humidity, which can lead to deterioration of materials and components.

Routine Servicing: Schedule regular maintenance checks with a professional to address any underlying issues before they become serious problems. Regular servicing helps in identifying and correcting minor issues that could affect performance.

Follow Manufacturer Guidelines: Always adhere to the maintenance instructions provided by the manufacturer. This ensures that you use the correct procedures and products, preserving the integrity of your equipment.

Common Mistakes to Avoid

When working with specialized tools and equipment, certain errors can significantly impact both the efficiency and outcome of your tasks. Identifying and avoiding these common pitfalls is crucial for ensuring smooth operation and achieving desired results.

- Neglecting Preparation: Always ensure that all components are correctly set up before starting your project. Failing to do so can lead to improper functioning and potential damage.

- Ignoring Safety Guidelines: Adhering to safety instructions is essential. Overlooking these precautions can result in accidents or harm.

- Using Incorrect Settings: Verify that all settings are appropriately adjusted for your specific task. Incorrect configurations can lead to inefficiency or equipment malfunction.

- Inadequate Maintenance: Regular upkeep of your equipment is necessary. Neglecting maintenance tasks can lead to breakdowns and reduced performance.

- Improper Handling: Be cautious when operating the equipment. Rough handling or misuse can cause errors and potentially damage the tool.

- Overlooking Calibration: Regularly check and calibrate your equipment to ensure accuracy. Failure to do so can result in inconsistent or incorrect results.

By being mindful of these common errors, you can enhance both the performance and longevity of your equipment while achieving better results in your projects.

Advanced Techniques for Precise Holes

Achieving accuracy in creating precise perforations requires a combination of skill and technique. This section delves into methods that enhance precision, ensuring that each hole is accurately placed and consistently sized. By employing advanced strategies and tools, you can refine your approach and achieve superior results in your work.

One effective method involves the use of specialized jigs and guides. These devices help maintain alignment and prevent deviations, allowing for consistent hole placement. Adjusting the depth and pressure settings on your equipment is crucial for achieving the desired results and avoiding common issues such as misalignment or uneven perforations.

Additionally, the selection of the appropriate materials and tools plays a significant role. Ensuring that your tools are sharp and well-maintained can drastically improve the precision of each perforation. Utilizing materials with consistent properties also helps in obtaining uniform results.

Experimenting with different techniques, such as incremental adjustments and trial runs, can provide valuable insights into the best practices for your specific needs. By continuously refining your approach and incorporating these advanced methods, you can elevate the accuracy and quality of your work.