Achieving optimal sterilization is essential in any medical or laboratory setting, where hygiene and precision are paramount. Understanding how to utilize specialized equipment effectively is crucial for ensuring that instruments are consistently prepared to the highest standards. This guide provides detailed insights into the use of one such device, designed to streamline and enhance the sterilization process, making it both faster and more reliable.

The content herein is designed to walk users through every step of operating this particular piece of equipment, offering clear and concise instructions to maximize efficiency. Whether you are new to this technology or looking to refine your technique, the following sections cover everything from setup to maintenance, ensuring that you are fully equipped to make the most of the sterilization process.

By adhering to the guidelines provided, users can significantly improve their workflow, reduce downtime, and maintain a high level of cleanliness and safety. This guide serves as a valuable resource for those aiming to perfect their approach to sterilization, ensuring consistent and dependable results every time.

Understanding the Midmark M7 Speedclave

Comprehending the operation and functionality of this sterilizer is essential for ensuring its effective use in any medical or dental setting. By grasping its core features and mechanisms, users can maximize efficiency and safety during sterilization processes.

This autoclave is designed for rapid sterilization, making it a reliable tool for maintaining a sterile environment. It combines straightforward controls with advanced technology to deliver consistent performance. Whether you are new to using this equipment or have experience, understanding its key components and how they work together will help you achieve optimal results.

In this section, we will explore the main elements that contribute to the autoclave’s operation, including its heating system, pressure controls, and safety features. By familiarizing yourself with these aspects, you can ensure that each sterilization cycle is performed correctly, leading to better outcomes in your practice.

Key Features and Specifications

This section highlights the primary attributes and technical details of the device, providing an overview of its capabilities and essential performance parameters. Understanding these features is crucial for effective utilization and maintenance.

Compact Design: The device is engineered with a space-saving design, making it ideal for environments with limited room. Its portability and efficient use of space are standout features.

Fast Cycle Time: Optimized for quick operation, the unit ensures rapid processing, significantly reducing downtime. This efficiency is key for high-throughput settings.

User-Friendly Interface: The control panel is intuitive and easy to navigate, featuring clear indicators and simple controls, enabling users to operate the unit with minimal training.

Durable Construction: Built with high-quality materials, the device is designed to withstand rigorous use, ensuring longevity and reliable performance over time.

Safety Mechanisms: Equipped with advanced safety features, the unit includes fail-safes and automatic shutdown functions to prevent overheating and ensure safe operation at all times.

Energy Efficiency: The device is designed with power-saving technologies, reducing energy consumption without compromising performance, making it an eco-friendly option.

Technical Specifications: The unit operates at a specific voltage and frequency, with precise dimensions and weight. It also includes specific capacity and cycle duration details, which are crucial for planning and operational purposes.

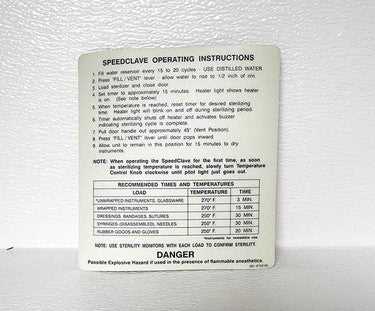

Step-by-Step Operating Instructions

This section provides a detailed guide on how to operate the sterilization equipment effectively. Follow the outlined steps carefully to ensure the process is performed correctly, maintaining safety and efficiency throughout the operation.

1. Preparing the Equipment

Start by ensuring that the device is clean and ready for use. Check that all components are in place, including any trays or containers, and that they are properly assembled. Fill the unit with the appropriate amount of water according to the specifications. Close the lid securely, making sure the seal is intact and the locking mechanism is engaged.

2. Setting the Controls

Select the desired temperature and pressure settings based on the items to be sterilized. Adjust the timer to the recommended duration for the specific load. Ensure all controls are correctly set before starting the cycle.

Once everything is set, initiate the cycle by pressing the start button. Monitor the progress through any available indicators or displays, ensuring that the process runs smoothly. If any issues arise, refer to troubleshooting guidelines to resolve them promptly.

After the cycle is complete, allow the equipment to cool down before opening. Carefully remove the sterilized items using protective gear if necessary, and store them appropriately. Finally, clean the unit after each use to maintain its condition and readiness for future operations.

Maintenance Tips for Longevity

Proper upkeep is crucial for ensuring the long-term functionality and efficiency of any equipment. Consistent care and routine checks not only extend the lifespan of the device but also contribute to its reliable operation. Below are essential maintenance practices that will help keep your equipment in prime condition for years to come.

| Task | Frequency | Details |

|---|---|---|

| Regular Cleaning | After Each Use | Thoroughly clean the chamber and accessories to prevent buildup of debris and residues that can impair functionality. |

| Inspect Seals and Gaskets | Weekly | Check all seals and gaskets for signs of wear or damage. Replace if necessary to maintain a proper airtight environment. |

| Lubrication | Monthly | Apply appropriate lubrication to moving parts to reduce friction and wear. Ensure to use the recommended lubricant type. |

| Check Water Quality | Monthly | Ensure that the water used is of the correct purity level. Impurities in water can lead to corrosion and reduce efficiency. |

| Professional Servicing | Annually | Schedule a professional inspection and maintenance service to check for hidden issues and perform any needed adjustments or repairs. |

By adhering to these maintenance tasks, you can help ensure that your equipment remains operational and efficient, reducing the likelihood of unexpected breakdowns and costly repairs.

Troubleshooting Common Issues

When operating any complex device, occasional malfunctions or inefficiencies can occur. This section offers guidance on identifying and resolving frequent operational problems, ensuring optimal performance and longevity of your equipment.

Problem: Device Not Reaching Proper Temperature

If the unit fails to achieve the desired temperature, first check the power source and ensure that the device is properly connected. Verify that the heating element is functioning correctly by inspecting for any visible signs of damage or wear. If the issue persists, consider recalibrating the thermostat or contacting a qualified technician for further assistance.

Problem: Pressure Not Building Up

In cases where the pressure does not build up as expected, inspect the seals and gaskets for any signs of wear or damage, as these components are crucial for maintaining proper pressure. Ensure that the chamber door is securely closed and locked. Additionally, verify that the pressure release valve is not obstructed or damaged. If necessary, replace worn-out parts to restore normal operation.

Note: Regular maintenance and timely replacement of critical components are key to preventing these common issues.

Safety Guidelines and Best Practices

Ensuring a safe working environment while using sterilization equipment is crucial for preventing accidents and maintaining optimal functionality. Adhering to proper procedures and safety measures helps safeguard both operators and equipment. This section outlines essential safety practices and recommendations for effective use and maintenance.

Operational Safety

1. Personal Protective Equipment (PPE): Always wear appropriate PPE, such as gloves and eye protection, when handling the sterilizer. This prevents exposure to potentially harmful substances and reduces the risk of injury.

2. Training and Familiarization: Operators should be thoroughly trained and familiar with the equipment’s operation and safety features. Regular training updates are recommended to ensure everyone is aware of any changes or improvements in procedures.

3. Equipment Inspection: Regularly inspect the sterilizer for any signs of wear or malfunction. Address any issues promptly to avoid potential hazards. Routine maintenance checks are essential for ensuring the equipment operates safely and efficiently.

Best Practices for Operation

1. Loading and Unloading: Follow the manufacturer’s guidelines for loading and unloading items. Overloading can affect performance and increase the risk of equipment failure. Ensure items are arranged correctly to allow proper steam penetration.

2. Proper Use of Indicators: Pay close attention to indicator lights and alarms. These signals provide important information about the sterilization process and alert you to any issues that may require immediate attention.

3. Record Keeping: Maintain accurate records of sterilization cycles and maintenance activities. Documenting these details helps track equipment performance and ensures compliance with safety standards.

By following these guidelines and best practices, you can enhance safety and efficiency while using sterilization equipment, contributing to a safer and more productive work environment.