Accurate vision assessment is fundamental in the field of optometry. The process requires precise tools that enable professionals to measure and evaluate various aspects of lenses with confidence. Understanding how to operate these tools efficiently is crucial for achieving reliable results in clinical practice.

This guide is designed to assist you in becoming proficient with a key device used for evaluating lenses. By exploring the functions, features, and proper handling of this essential equipment, you will be equipped with the knowledge to conduct assessments with greater precision.

Whether you’re new to the field or looking to enhance your expertise, this resource provides a step-by-step approach to mastering this indispensable tool. Dive in to learn the critical techniques and best practices that will elevate your proficiency in optical measurements.

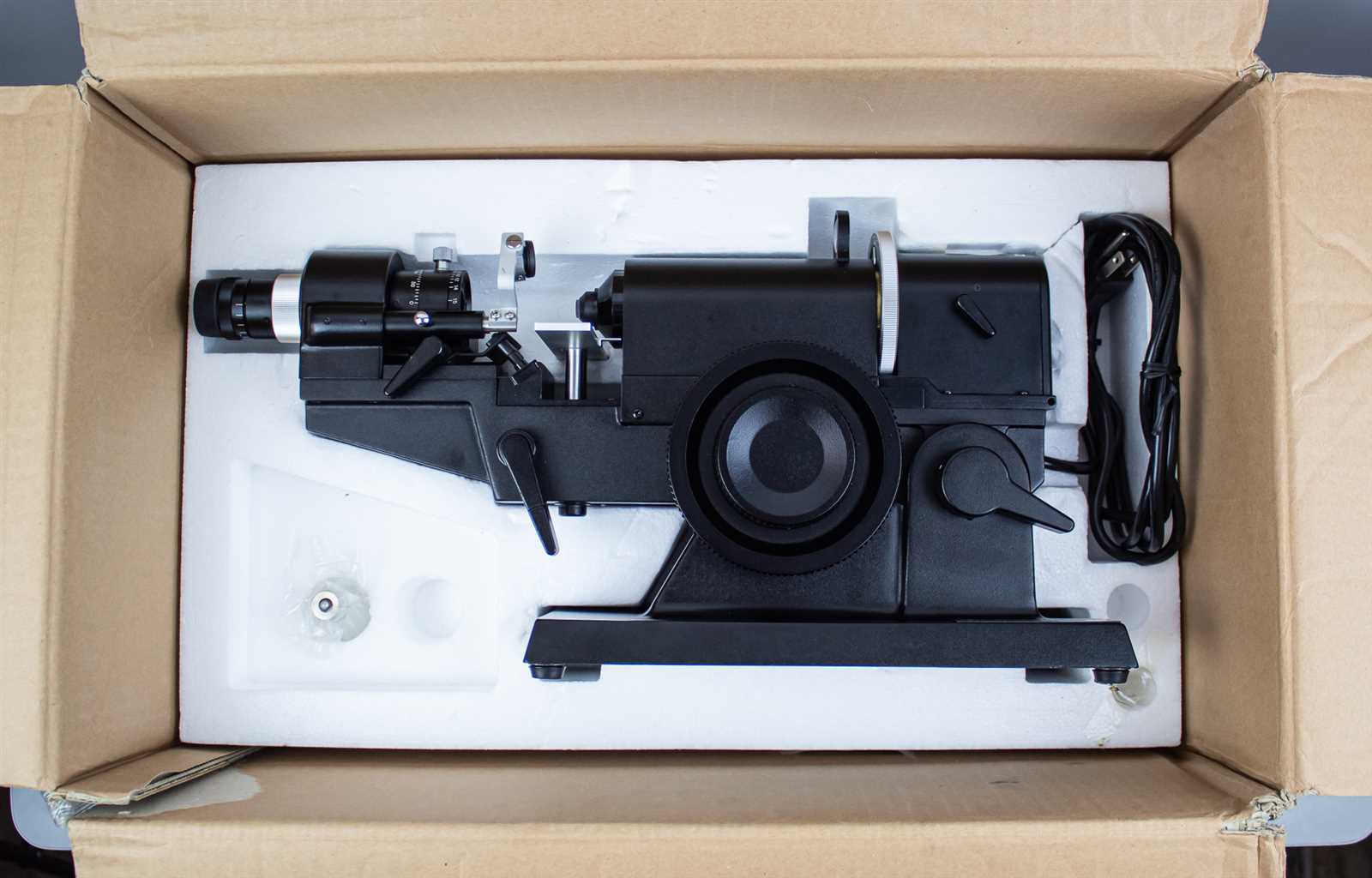

Overview of the Marco 101 Lensmeter

This precision optical instrument is essential for professionals who need to measure the properties of lenses accurately. It offers reliable performance and precise measurements, making it an indispensable tool for anyone working with eyewear. This overview covers its key features, usage, and benefits.

Key Features

- Accuracy: Delivers high-precision readings, ensuring dependable results for lens verification.

- Ease of Use: Intuitive design allows for straightforward operation, even for those new to the field.

- Versatility: Compatible with various types of lenses, including progressive, bifocal, and single-vision.

- Durability: Built with robust materials, ensuring long-lasting performance in a professional setting.

Usage and Applications

This optical device is commonly employed in optometry practices, eyewear retail, and laboratories. It assists in measuring sphere, cylinder, and axis parameters, essential for creating and verifying prescription lenses. By providing accurate data, it supports the fitting process and ensures that patients receive correctly tailored eyewear.

- Calibration: Regular calibration ensures consistent performance and accuracy.

- Lens Alignment: Precise alignment is crucial for obtaining correct measurements.

- Data Interpretation: Clear and easy-to-read displays help interpret results efficiently.

This tool is invaluable for anyone involved in the lens crafting and fitting process, ensuring that each lens meets the specific needs of the wearer.

Getting Started with Your Lensmeter

Before you begin utilizing your new optical instrument, it’s essential to understand the basic steps that will set you up for successful operation. Familiarizing yourself with the initial setup and key features will ensure that you achieve precise and accurate measurements every time.

Initial Setup

Start by ensuring that your device is securely placed on a stable surface, free from vibrations or movements that could affect its accuracy. Once positioned, connect the device to a power source, and turn it on. Allow the instrument to warm up for a few minutes to stabilize its internal components.

Understanding the Controls

Next, take a moment to familiarize yourself with the primary controls and adjustments available on your device. These typically include knobs or dials for adjusting focus, alignment, and calibration. Knowing how to properly manipulate these controls is crucial for obtaining reliable results. Begin by adjusting the focus to match your visual preference, ensuring that the readings are clear and easy to interpret.

Following these initial steps will prepare you to start using your optical tool effectively, allowing you to achieve the accurate readings you need in your practice.

Step-by-Step Calibration Instructions

Proper calibration is essential for ensuring accurate measurements in your optical instrument. The following guide provides a clear, step-by-step approach to calibrating your device, ensuring its performance remains precise and reliable over time.

- Initial Setup: Begin by setting up the device on a stable, level surface. Ensure that it is turned off before starting the calibration process.

- Power On: Once the device is securely positioned, power it on and allow it to warm up for the recommended time. This step is crucial for stabilizing internal components.

- Reference Lens Placement: Insert the reference lens into the appropriate holder. Ensure that the lens is clean and free from any debris to avoid inaccuracies.

- Adjust Focus: Use the focus adjustment knob to bring the reference lens into clear view. The target image should be sharp and well-defined.

- Set Zero Point: Align the measuring dial to the zero position, ensuring that all scales read correctly. This step is critical to establish a baseline for future measurements.

- Verification: After setting the zero point, remove the reference lens and test with a known standard. Compare the readings to confirm accuracy. If necessary, make fine adjustments.

- Final Check: Perform a final check by measuring multiple known standards to ensure consistency across various measurements.

- Completion: Once all steps are satisfactorily completed, the device is now calibrated. It is ready for use in obtaining precise optical measurements.

Regular calibration is recommended to maintain the accuracy and reliability of the instrument, especially after significant usage or transport.

Common Troubleshooting Tips and Solutions

When working with precision instruments, occasional issues can arise that may impact the accuracy or functionality of the device. Understanding common problems and their solutions can help maintain optimal performance and prevent unnecessary downtime. Below are some practical tips for diagnosing and resolving frequent challenges encountered during use.

Device Not Powering On: Ensure that the power source is securely connected and functional. Check for any loose connections or damaged cables. If the device remains unresponsive, try a different outlet or power source. Additionally, inspect the fuse or power switch for any visible issues.

Inconsistent Readings: If measurements appear inconsistent, verify that the instrument is properly calibrated. Recalibrate the device following the recommended procedure if needed. Also, ensure that the lens or object being measured is correctly positioned and free from debris or smudges that could interfere with accuracy.

Display or Screen Issues: If the screen is flickering, dim, or unresponsive, check the brightness settings and adjust as necessary. For display malfunctions, reset the device by turning it off and then back on. Persistent issues may require a software update or professional maintenance.

Operational Errors: If the device is displaying error messages or behaving unexpectedly, refer to the error codes in the user guide to determine the cause. Resetting the system or performing a factory reset may resolve the problem. Ensure that all settings are correctly configured for the intended use.

These troubleshooting strategies can address most common issues, helping you maintain reliable and accurate operation. For more complex problems, seeking professional assistance is recommended to avoid damage or incorrect adjustments.

Maintaining Optimal Performance of the Device

Ensuring that your optical measurement equipment operates at its best requires consistent care and attention. Regular upkeep not only prolongs the life of the device but also guarantees precise and accurate results in your daily practice. By following a few key maintenance practices, you can prevent malfunctions and maintain the reliability of your equipment.

Regular Cleaning

One of the fundamental aspects of keeping your device in top condition is routine cleaning. Dust and debris can accumulate on lenses and sensitive components, which may affect the accuracy of measurements. Use a soft, lint-free cloth to gently clean all optical surfaces. Avoid using harsh chemicals that could damage the delicate materials. Additionally, ensure that the device is stored in a clean, dry environment when not in use to minimize exposure to contaminants.

Periodic Calibration

Over time, even the most well-maintained equipment may require recalibration to ensure ongoing accuracy. Regular calibration checks, performed according to the manufacturer’s recommendations, help maintain the precision of your measurements. If you notice any deviations or inconsistencies, it’s important to recalibrate immediately to avoid incorrect readings that could impact your work.

By adhering to these maintenance practices, you can ensure that your equipment remains in excellent working condition, providing reliable and accurate results for years to come.

Understanding the Key Features and Functions

Getting acquainted with the essential characteristics and operations of optical measurement devices is crucial for effective use. These instruments are designed to offer precise readings and valuable insights into the quality and specifications of lenses. By familiarizing yourself with their core functionalities, you can ensure accurate assessments and improve your proficiency in handling such equipment.

Primary Functions

- Measurement Accuracy: Ensures that the optical device provides precise readings of lens parameters, crucial for accurate prescriptions and adjustments.

- Ease of Calibration: Facilitates simple and effective adjustment procedures to maintain measurement precision over time.

- Display Options: Offers various display modes to present measurements in a clear and comprehensible format, aiding in quick decision-making.

Key Features

- Automatic Measurements: Provides automated processes for faster and more reliable data collection.

- Lens Alignment: Includes mechanisms for proper alignment of lenses to ensure that measurements are taken from the correct angle.

- Data Storage: Allows for the recording and retrieval of measurement data, which is useful for tracking changes and making informed decisions.