Ensuring the efficient operation of a fluid management system is crucial for maintaining performance and safety. This segment introduces a comprehensive overview of the components and processes involved in managing the flow and protection mechanisms within such systems. By understanding these elements, users can achieve optimal functionality and safeguard against potential issues.

The following sections delve into the essential aspects of this technology, offering insights into its setup and usage. Emphasis will be placed on enhancing the reliability and effectiveness of your system. Through detailed instructions and practical advice, users will gain valuable knowledge for efficient system maintenance and operation.

Flow Guard Overview

The system described here is designed to ensure effective management of liquid flows within various environments. It offers a range of features intended to enhance safety and efficiency in handling fluids, contributing to smoother operations and preventing potential issues.

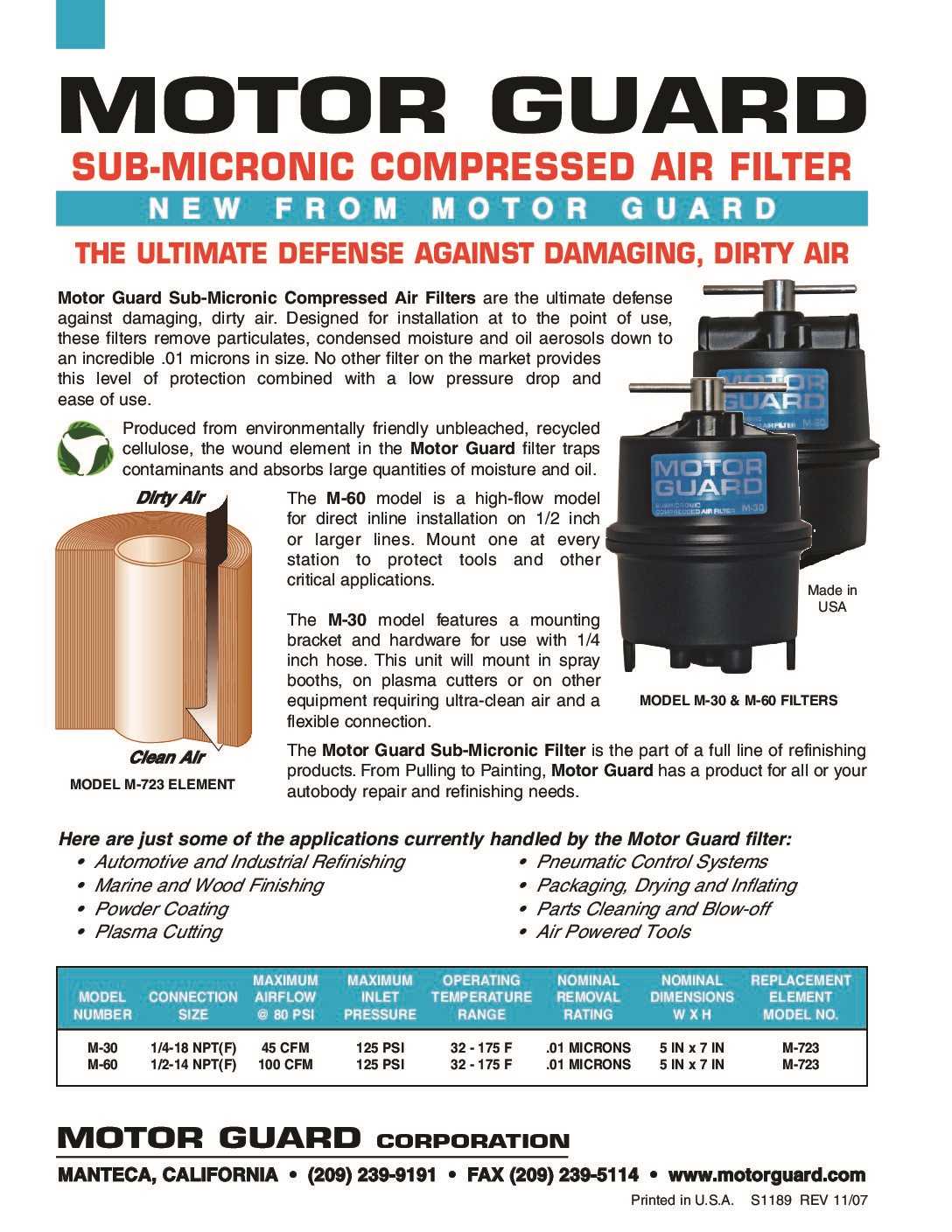

Key Features

This system includes advanced mechanisms for regulating and monitoring the movement of liquids. Its design focuses on providing reliable performance and reducing the risk of leaks or overflows, thereby maintaining optimal operational conditions.

Benefits

Implementing this solution results in improved fluid control, which can lead to greater efficiency and safety in applications where precise management of liquid flow is crucial. Users can expect enhanced reliability and a reduction in maintenance needs.

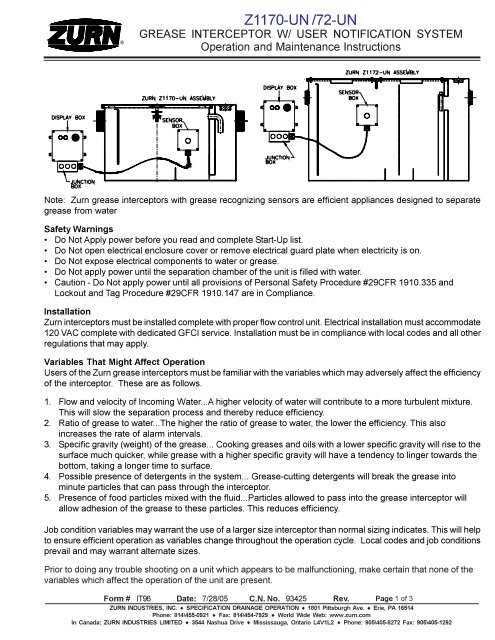

Installation Guide

Setting up the device involves several key steps to ensure proper functionality and safety. This section will provide a comprehensive overview of the procedures required for a successful setup.

Begin by carefully reviewing the setup procedure outlined in this guide. Make sure to follow each step in the specified order to avoid any issues during installation. Pay particular attention to any preparation requirements and installation tips provided, as these will assist in achieving optimal performance.

After completing the initial setup, verify that all connections are secure and that the device is positioned correctly. Perform any necessary adjustments and ensure that everything is operating as expected. Following these guidelines will help ensure a smooth and efficient installation process.

Steps for Proper Setup

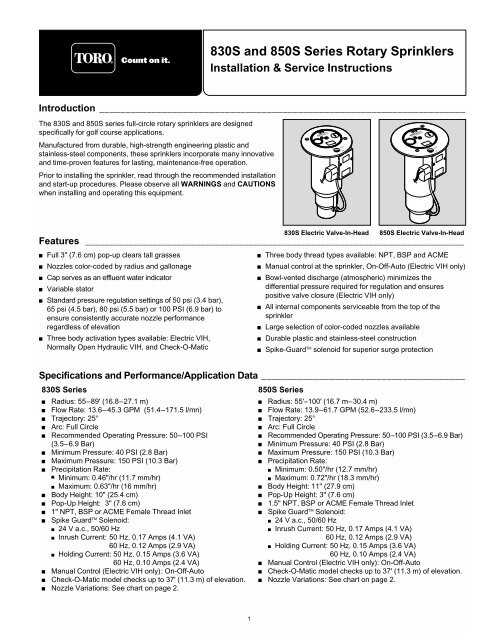

Setting up your system correctly ensures optimal performance and longevity. Follow these guidelines to ensure a smooth installation process. Begin by preparing all necessary components and verifying their condition to avoid any issues during setup.

Preparation and Assembly

First, gather all parts and tools required for the setup. Ensure that each component is free from damage and that you have all the pieces needed. Assemble the unit according to the provided schematics, making sure each part is securely connected.

Installation and Calibration

Once assembled, proceed to install the system in the designated location. Ensure that it is placed on a level surface and connected to the appropriate utilities. After installation, perform a calibration process to adjust settings for optimal functionality. This step is crucial for accurate and efficient operation.

Operational Instructions

In this section, you will learn how to efficiently utilize and manage your device to ensure optimal performance. This guide aims to provide clear steps for everyday use and maintenance, making sure you get the best results.

Initial Setup

- Unpack the unit and ensure all parts are included as per the checklist.

- Find a suitable location for installation, ensuring accessibility and safety.

- Connect the device according to the provided guidelines, ensuring all connections are secure.

Daily Operations

- Power on the unit and allow it to complete its initialization process.

- Adjust the settings to match your specific needs using the control panel.

- Monitor the system periodically to ensure it is functioning correctly and efficiently.

How to Use Flow Guard

Effectively managing the system requires understanding its operation and following specific steps to ensure optimal performance. This guide provides a comprehensive overview of how to utilize the system correctly, helping you maintain smooth operation and prevent issues.

- Begin by familiarizing yourself with the setup. Review the components and their functions to understand how they interact within the system.

- Ensure all connections are secure and correctly installed. Check for any leaks or loose fittings that might affect performance.

- Adjust the settings according to the needs of your system. Refer to the specifications provided to configure the system accurately.

- Regularly monitor the system’s performance. Look for any irregularities and address them promptly to avoid disruptions.

- Perform routine maintenance as recommended. This includes cleaning, checking for wear and tear, and replacing any worn-out parts to ensure longevity.

Following these steps will help maintain the efficiency and reliability of your system, ensuring that it operates as intended.

Maintenance Tips

Proper upkeep is essential to ensure the longevity and efficiency of your system. Regular care can prevent malfunctions and enhance performance, ultimately saving time and resources. This section provides crucial advice for maintaining your equipment effectively.

| Task | Frequency | Description |

|---|---|---|

| Inspection | Monthly | Check for any signs of wear or damage and ensure all components are functioning correctly. |

| Cleaning | Quarterly | Remove debris and buildup from parts to prevent clogging and maintain optimal performance. |

| Lubrication | Every 6 months | Apply appropriate lubricants to moving parts to reduce friction and prevent premature wear. |

| Calibration | Annually | Ensure that the system is properly calibrated to maintain accuracy and efficiency. |

Following these guidelines will help in maintaining the equipment in peak condition, ultimately contributing to its effectiveness and longevity. Regular maintenance is key to avoiding unexpected issues and ensuring smooth operation.

Keeping Your Device in Top Shape

Maintaining optimal performance and longevity of your equipment requires a systematic approach. Regular care and attention ensure that your device remains functional and efficient over time. Adhering to a few essential practices can prevent common issues and extend the lifespan of your device.

Firstly, ensure that you regularly inspect and clean your equipment. Dust and debris can accumulate, potentially affecting its functionality. Using appropriate cleaning tools and methods will help keep your device in pristine condition.

Additionally, monitoring and managing any potential wear and tear is crucial. Regular checks for any signs of damage or malfunction can prevent minor issues from becoming major problems. Promptly addressing these issues will save you from costly repairs or replacements.

Finally, adhering to the recommended maintenance schedule is essential. Follow the guidelines provided for optimal upkeep to ensure that your device continues to operate smoothly and efficiently.

Troubleshooting Common Issues

When encountering difficulties with your system, it is important to systematically address common problems to restore optimal functionality. This section provides guidance on identifying and resolving frequent malfunctions that users may experience.

No Response from the System

If your device fails to respond, ensure that it is properly connected to the power source and that all cables are securely attached. Check for any visible signs of damage to the components and verify that the power switch is turned on. Additionally, consult the power indicator lights to confirm that the unit is receiving electricity.

Inconsistent Performance

Should you notice irregular performance, it could be due to blockages or obstructions within the mechanism. Inspect the internal parts for any debris or buildup that may be affecting operation. Regular maintenance and cleaning can help in maintaining consistent performance. Ensure that all settings are correctly adjusted according to the requirements of your setup.

Leakage Issues

If you observe any signs of leakage, inspect the seals and connections for any signs of wear or damage. Tighten any loose fittings and replace any defective seals to prevent further issues. It’s also important to check that the fluid levels are within the recommended range and that there are no cracks in the housing.

Unusual Noises

Unusual sounds may indicate mechanical problems or misalignment within the system. Listen carefully to identify whether the noise is coming from a specific part and check for any loose or worn components. Addressing these issues promptly can prevent further damage and ensure smooth operation.