Understanding how to effectively utilize a versatile textile device can open up a world of creativity and efficiency in your fabric projects. Whether

Necchi Sewing Machine Setup and Configuration

In this section, we will explore the process of preparing and fine-tuning your device to ensure smooth and efficient operation. This involves a series of steps that require attention to detail and understanding of the various components.

Unboxing and Initial Assembly

- Carefully remove the device from its packaging and identify all included parts.

- Assemble the components, ensuring that each part is securely attached and properly aligned.

- Place the unit on a stable surface, making sure it is positioned for easy access during use.

Configuring Settings and Adjustments

- Plug the unit into a power source and switch it on.

- Adjust the tension settings based on the type of fabric you will be working with.

- Select the desired stitch pattern, considering the specific requirements of your project.

- Thread the device according to the diagram provided, ensuring that the thread is properly positioned to avoid any issues during operation.

Following these steps will ensure that your device is ready for use, providing you with the necessary foundation

Operating Procedures for Necchi Models

Understanding the steps required to utilize your equipment effectively is crucial for achieving optimal results. Whether you’re working on delicate fabrics or more robust materials, following the correct sequence of actions will ensure precision and consistency in your projects. This guide will outline the essential tasks involved, from preparing the device to executing various techniques, enabling you to harness its full potential.

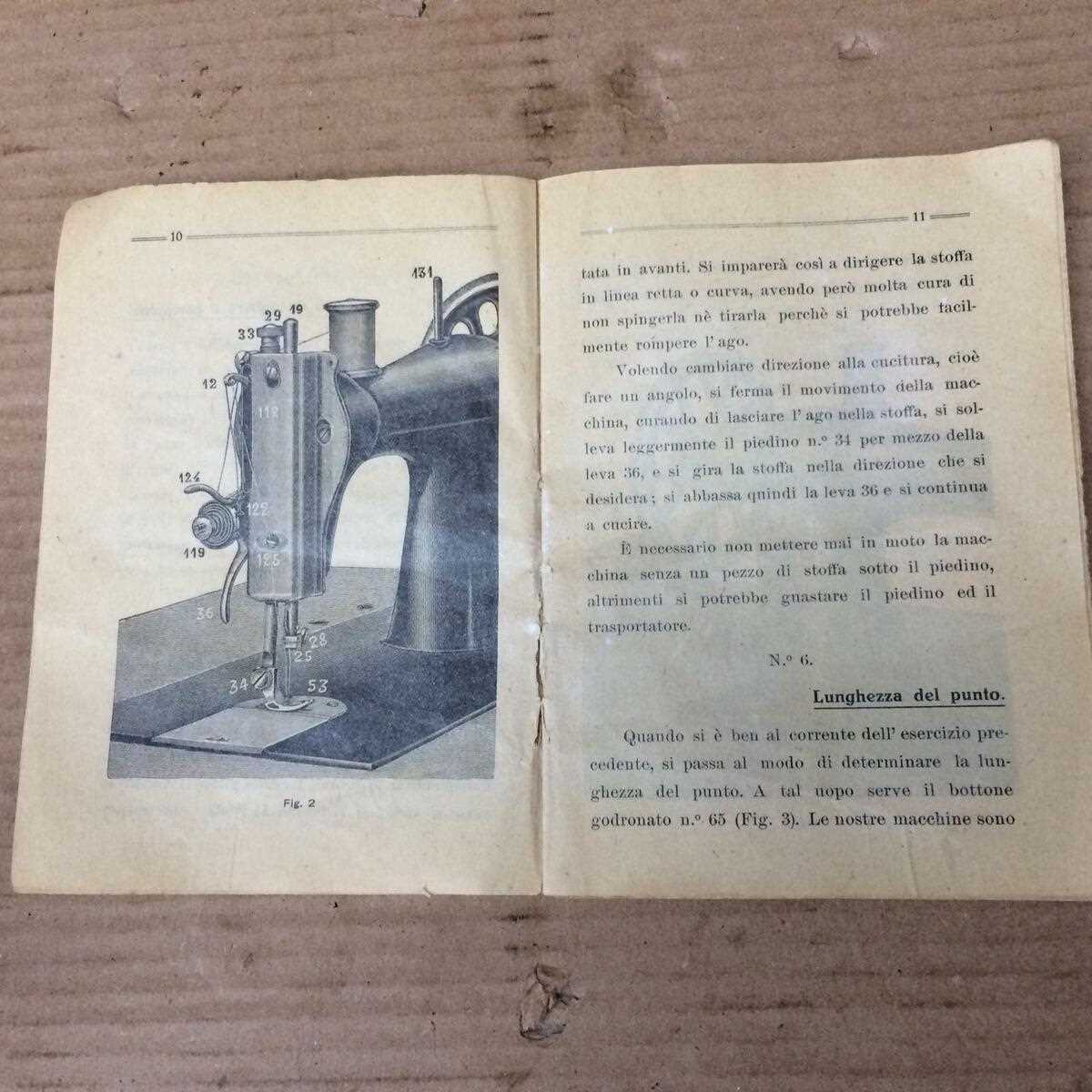

Device Setup: Begin by ensuring the workspace is well-lit and organized. Position the equipment on a stable surface, and check that all necessary components are properly aligned and secured. Threading the device correctly is vital–refer to the threading diagram or chart, and take care to follow each step meticulously to avoid any operational issues.

Basic Operation: Once the setup is complete, adjust the settings according to the type of material you’re using. This may include selecting the appropriate tension, stitch length, and speed. Familiarize yourself with the control panel, and practice using the foot pedal to maintain a steady rhythm. Starting with a test piece of fabric can help you fine-tune these settings before beginning your main project.

Advanced Techniques: For more complex projects, such as creating buttonholes or applying decorative stitches, consult the model-specific features. Many devices come with attachments or special functions designed to simpl

Maintenance Tips for Longevity and Performance

To ensure that your equipment remains in optimal condition and delivers consistent results, it’s essential to perform regular upkeep. By following a few key practices, you can extend the lifespan of your device and maintain its efficiency over time.

Regular Cleaning

Dust and lint can accumulate over time, potentially hindering the performance of your device. It’s important to regularly clean all accessible areas, including the bobbin case and feed dogs, to prevent buildup that can cause issues during operation. Use a small brush or compressed air to carefully remove any debris.

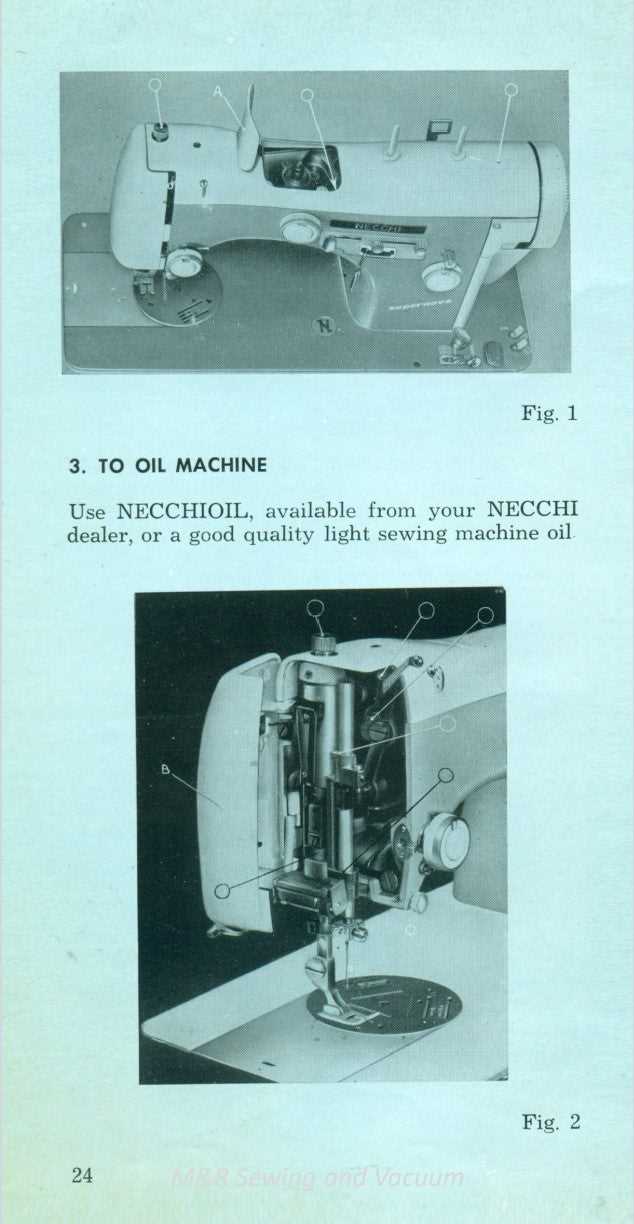

Proper Lubrication

Lubrication is crucial to keeping the internal components of your equipment functioning smoothly. Apply a few drops of the recommended oil to moving parts as specified by the manufacturer. This helps reduce friction and wear, ensuring that your device continues to operate seamlessly.

| Maintenance Task | Frequency | Purpose |

|---|---|---|

| Cleaning | Weekly | Remove debris and lint |

| Lubrication | Monthly | Ensure smooth operation |

Common Issues and Troubleshooting Techniques

Encountering challenges while operating your device can be frustrating, but with the right approach, these obstacles can be easily overcome. This section provides a clear pathway to identifying and resolving typical problems that may arise during use, ensuring smooth and efficient operation.

Threading Problems

One frequent issue users face is improper threading, which can lead to skipped stitches or tangled threads. To address this, carefully review the threading path, ensuring each step is followed correctly. Pay special attention to tension settings, as incorrect tension can cause further complications. Adjusting the tension dial and re-threading the device can often resolve these issues.

Uneven Stitching

Another common problem is uneven stitching, where stitches appear inconsistent or bunched. This can result from various factors, such as incorrect needle type or size, or using inappropriate thread. To troubleshoot, first check the needle to ensure it is suitable for the material being worked on. Additionally, confirm that the fabric is properly aligned and that the presser foot pressure is adjusted accordingly. Replacing the needle and rechecking the fabric positioning can often restore uniform stitching.

Understanding and Adjusting Stitch Patterns

Exploring various stitch designs and fine-tuning them to suit your fabric and project needs is an essential skill. Each pattern offers unique characteristics that can enhance the appearance and durability of your work. By learning how to modify these settings, you can achieve the desired outcome, whether it’s a decorative finish or a functional seam.

Below is a table detailing common stitch types and their adjustments:

| Pattern Type | Characteristic | Adjustment Tips |

|---|---|---|

| Zigzag | Flexible, great for stretch fabrics | Widen or narrow the width to match the material’s stretch |

| Straight | Basic, strong for most fabrics | Adjust length for thicker or thinner materials |

| Buttonhole | Creates secure openings | Ensure even spacing and correct width |

| Blind Hem | Invisible finish on hems |