Understanding the operation and maintenance of your sewing apparatus is crucial for achieving optimal performance and longevity. This segment aims to provide you with detailed insights into the setup, functionality, and care of your specific model, ensuring that you can harness its full potential with ease.

In this guide, you will discover step-by-step instructions tailored to help you become proficient with your equipment. From assembling and configuring the components to troubleshooting common issues, every aspect has been covered to facilitate a seamless sewing experience.

Whether you are a seasoned professional or a newcomer to the world of stitching, this resource will equip you with the knowledge needed to handle your machine effectively. Embrace the opportunity to enhance your skills and ensure your sewing tasks are executed with precision and efficiency.

Overview of Willcox & Gibbs 500-4

The model in focus represents a sophisticated piece of sewing machinery designed for industrial and advanced home use. It integrates precision engineering with user-friendly features, making it a valuable tool for those who require high-quality stitching in their projects. The equipment is built to enhance efficiency and accuracy, offering robust performance in a variety of sewing tasks.

Key Features

- Advanced stitching mechanisms for consistent and reliable output.

- Durable construction suited for intensive use.

- Adjustable settings to cater to different types of fabrics and stitching needs.

- Innovative design elements aimed at simplifying the sewing process.

Usage and Maintenance

Proper usage and regular upkeep are essential to ensure optimal performance. Familiarize yourself with the basic operating procedures and maintenance guidelines to keep the machinery in top condition. Regular cleaning, lubrication, and timely adjustments will contribute to the longevity and efficiency of the equipment.

Key Features of the 500-4 Model

The 500-4 model stands out for its remarkable functionality and innovative design, which are tailored to meet the needs of both professionals and enthusiasts. This device integrates advanced technology with user-friendly features, making it a versatile choice for a wide range of applications. Its sophisticated engineering ensures reliable performance and precision, setting it apart from other models in its class.

One of the most notable aspects is its robust construction, which guarantees durability and long-term use. The equipment is designed with a focus on efficiency, offering streamlined operation and minimal maintenance requirements. Additionally, its ergonomic design enhances user comfort and accessibility, making it easy to handle and operate.

Another significant feature is its adaptability to various tasks, providing flexibility and convenience. The model is equipped with state-of-the-art components that contribute to its high performance and accuracy. These features collectively ensure that the equipment meets the diverse needs of its users while maintaining exceptional quality and reliability.

Setting Up Your Willcox & Gibbs Machine

Proper setup of your sewing device is crucial for optimal performance and longevity. Ensuring that all components are correctly assembled and adjusted will facilitate smooth operation and accurate stitching. This section will guide you through the essential steps to get your machine ready for use.

- Initial Unpacking: Begin by carefully unpacking all parts of the machine. Verify that you have received all components listed in the package, including the main unit, accessories, and any additional tools.

- Placement: Position the machine on a stable, flat surface to ensure balanced operation. Make sure there is adequate space around the machine for ease of movement and accessibility.

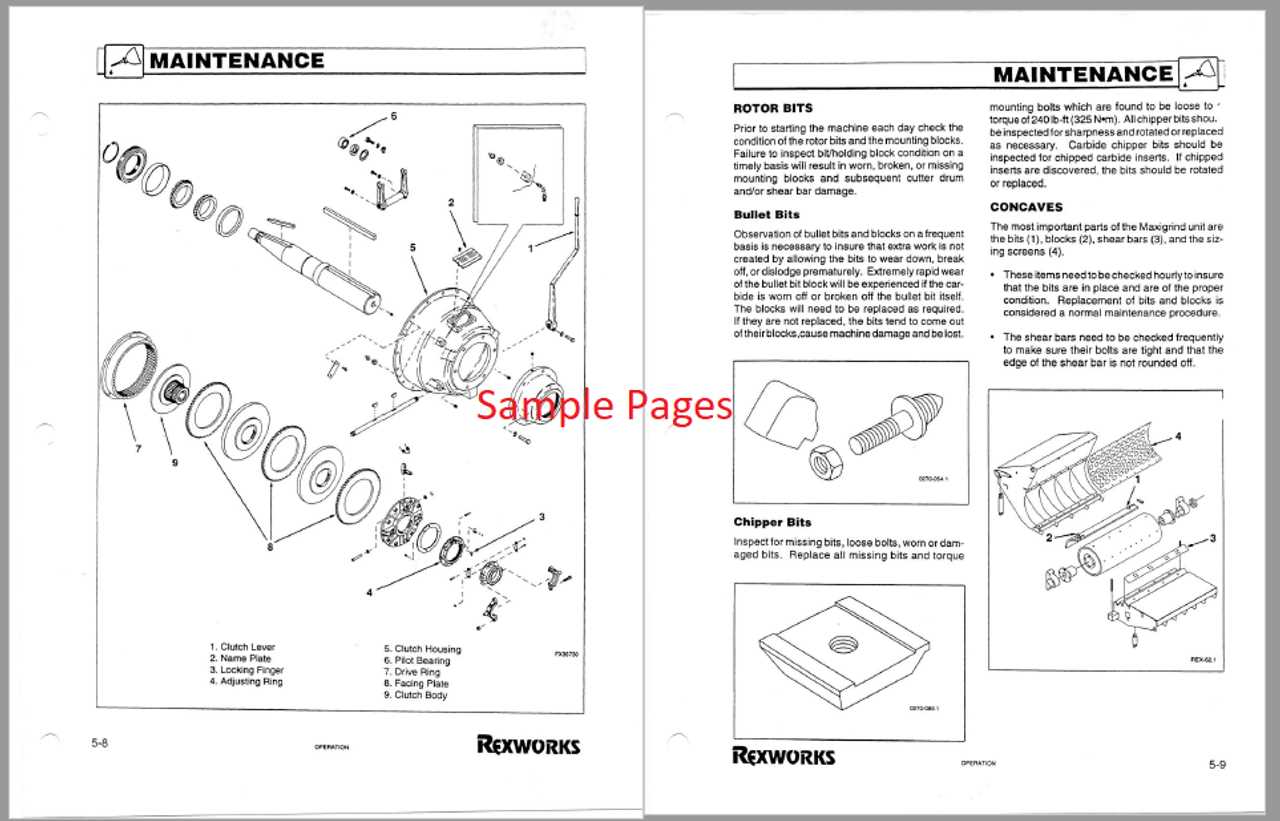

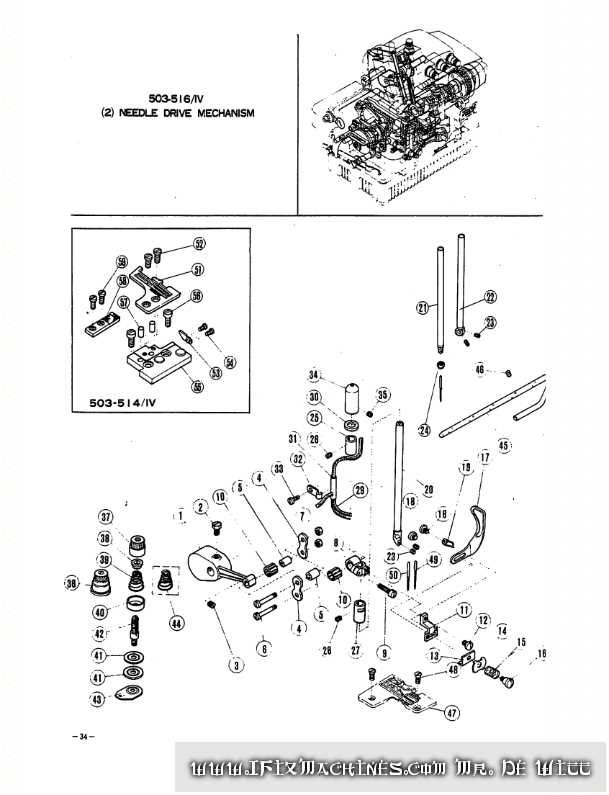

- Assembling Parts: Follow the instructions for attaching key components. This often includes the needle, presser foot, and bobbin case. Refer to the specific guidelines for your model to ensure correct assembly.

- Threading: Proper threading is essential for efficient operation. Thread the upper and lower threads according to the provided directions, ensuring that they are correctly aligned and tensioned.

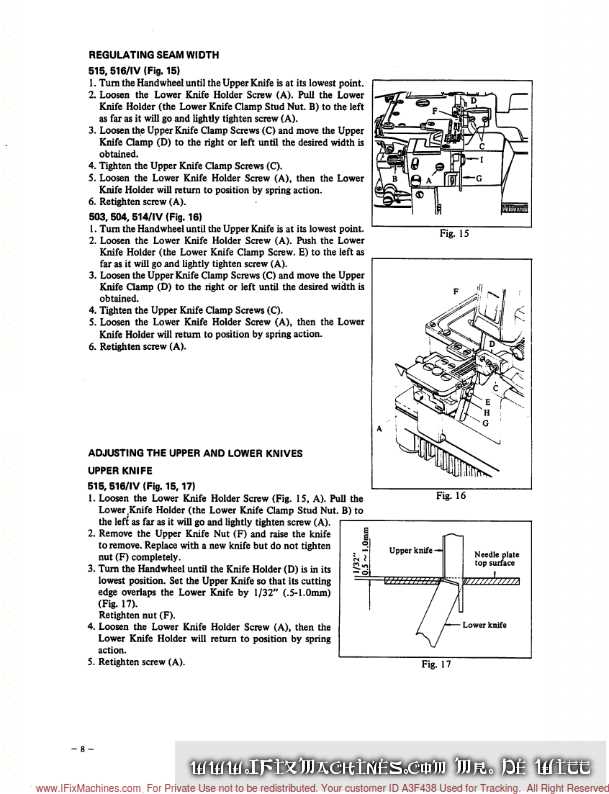

- Adjusting Tension: Set the thread tension according to the fabric and thread type you will be using. Proper tension adjustment will help in achieving even and consistent stitching.

- Testing: Before starting any actual sewing, conduct a test run on a scrap piece of fabric. This will help you verify that the machine is set up correctly and adjust any settings if necessary.

- Regular Maintenance: Familiarize yourself with the routine maintenance procedures to keep your machine in good working condition. This includes cleaning, oiling, and periodic checks.

lessCopy code

By following these setup steps, you can ensure that your sewing machine is properly configured and ready to deliver high-quality results. Always refer to the specific details provided for your machine model to address any unique setup requirements.

Basic Operation Guidelines for Beginners

When starting with a new sewing machine, it’s crucial to grasp the fundamental procedures to ensure smooth operation. This guide is designed to help beginners get acquainted with essential functions and practices that will facilitate a successful sewing experience.

Here are the core steps to follow:

- Understanding the Machine: Familiarize yourself with the machine’s parts and their functions. This includes learning about the needle, thread tension, bobbin, and various dials or levers.

- Setting Up the Thread: Thread the machine carefully, following the threading path indicated. Make sure the thread is properly seated in the tension discs.

- Inserting the Bobbin: Place the bobbin into its compartment as directed. Ensure it is properly wound and positioned to prevent issues during sewing.

- Adjusting the Tension: Set the thread tension according to the type of fabric and thread you are using. Proper tension is crucial for balanced stitches.

- Practicing Stitching: Begin with basic stitching exercises on scrap fabric. Adjust settings such as stitch length and width as needed to see how they affect the stitching.

By following these basic guidelines, you will be able to operate your sewing machine more effectively and start working on your projects with greater confidence.

Troubleshooting Common Issues

Addressing common malfunctions and inefficiencies requires a systematic approach. This section provides guidance on resolving frequent problems encountered with your equipment. By following these troubleshooting steps, you can efficiently diagnose and fix typical issues, ensuring smooth operation.

Below is a table of frequent problems and their solutions:

| Issue | Possible Cause | Solution |

|---|---|---|

| Machine Not Starting | Power supply issue | Check if the power cord is properly connected and the outlet is functioning. Verify that the power switch is turned on. |

| Unusual Noise During Operation | Loose or worn parts | Inspect and tighten any loose components. Replace any worn-out parts as necessary. |

| Inefficient Performance | Clogged or dirty components | Clean and clear any blockages in the system. Ensure all filters and moving parts are free of debris. |

| Irregular Output | Misalignment or incorrect settings | Check the alignment of components and verify that all settings are correctly adjusted according to the specifications. |

By adhering to these troubleshooting tips, you can effectively address and resolve the most common issues that may arise. Regular maintenance and attention to these details will help maintain optimal performance of your equipment.

Maintenance Tips for Longevity

To ensure the extended lifespan and optimal performance of your equipment, regular upkeep is essential. Proper care and consistent maintenance routines can significantly enhance durability and efficiency. By following a few key practices, you can prevent potential issues and extend the service life of your machinery.

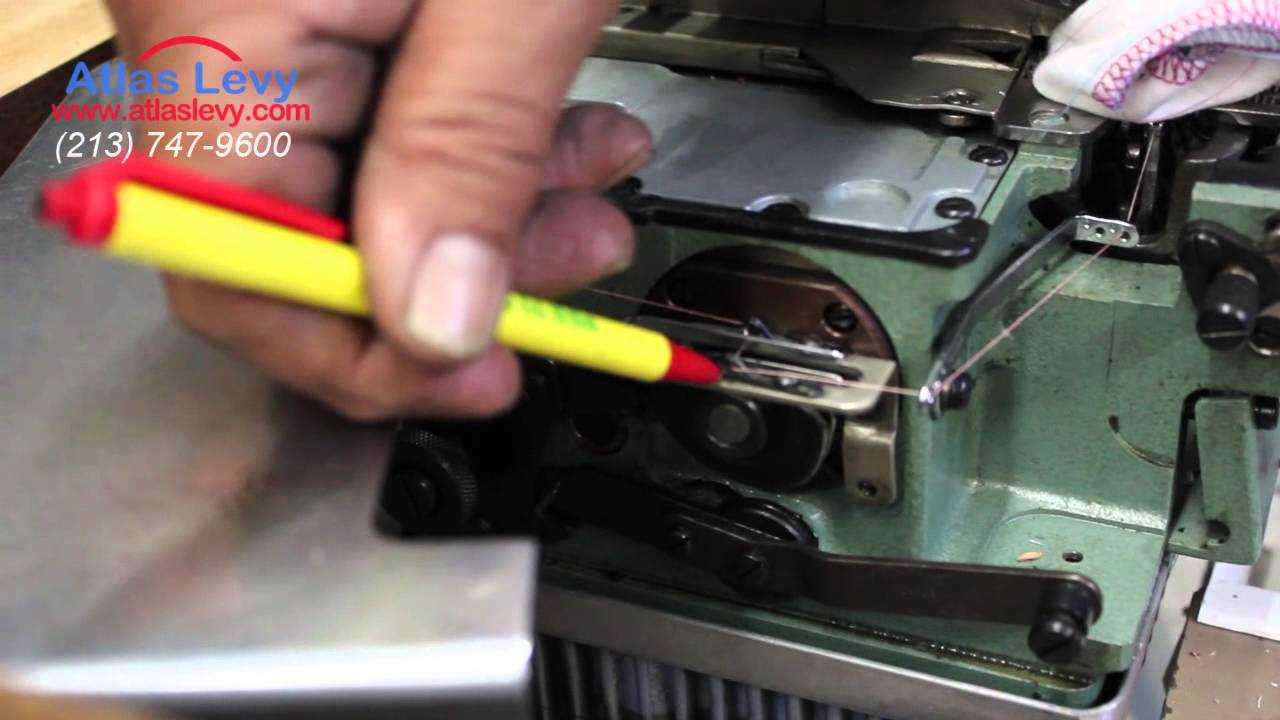

Routine Inspection

Performing regular inspections is crucial for early detection of wear and tear. Check for any signs of damage, loose components, or irregularities in operation. Addressing minor issues promptly can prevent more serious problems from developing.

Cleaning and Lubrication

Maintaining cleanliness is vital for smooth functioning. Ensure that the equipment is free from dust, debris, and other contaminants. Additionally, proper lubrication of moving parts reduces friction and wear, contributing to better performance and longevity.

Adhering to these maintenance practices will help in keeping your machinery in excellent condition and extend its useful life, ensuring reliable operation over time.

Where to Find Replacement Parts

Finding suitable replacement components for your sewing machine is crucial for maintaining its performance and longevity. Whether you need a specific gear, needle, or any other part, knowing where to look can save you time and ensure that you obtain high-quality items.

Authorized Dealers

One of the most reliable sources for obtaining authentic replacement parts is through authorized dealers. These vendors are certified to sell original components and can offer expert advice on what is compatible with your equipment. To locate an authorized dealer, consider the following:

- Visit the official website of the manufacturer to find a list of authorized sellers.

- Contact customer service for recommendations on trusted dealers in your area.

- Check with local sewing machine shops that may be affiliated with the manufacturer.

Online Marketplaces

Another option is to explore various online platforms that specialize in sewing machine parts. These marketplaces often have a wide range of components, including both original and aftermarket options. To ensure you make a satisfactory purchase, follow these tips:

- Use search filters to narrow down your options by model number and part type.

- Read customer reviews to gauge the reliability and quality of the seller.

- Compare prices across different platforms to find the best deal.

By exploring these sources, you can find the necessary replacement parts to keep your sewing machine running smoothly and efficiently.