Understanding how to effectively use your sewing equipment is essential for achieving the best results in your projects. This section provides a thorough overview of the device’s key features, functions, and operational steps, ensuring you can make the most of your machine. Whether you’re new to sewing or looking to refine your skills, this guide will be your go-to resource for mastering your equipment.

Exploring the Machine’s Capabilities

The guide offers detailed explanations on the various settings and adjustments available, helping you to tailor the machine’s performance to your specific needs. From basic stitching to more complex techniques, you will find the necessary instructions to navigate through each function with ease.

Step-by-Step Operation Instructions

To ensure smooth and efficient usage, this section breaks down the operating procedures into clear, manageable steps. You’ll learn how to set up the machine, select appropriate settings, and troubleshoot common issues, enabling you to focus on your creative process without unnecessary interruptions.

Getting Started with the Singer Simple 3337

Welcome to the world of sewing, where creating your own fabric masterpieces is just a few steps away. In this section, you’ll learn the basics of preparing your machine for its first use. We’ll cover essential setup procedures and ensure that you’re ready to begin your journey into crafting. This guide is designed to make your experience smooth and enjoyable, providing you with the foundational knowledge needed for a successful start.

Before diving into your first project, it’s important to familiarize yourself with the key components and initial steps required to prepare your sewing machine. The following table outlines the primary elements you need to focus on before beginning your first stitch:

| Component | Description |

|---|---|

| Power Connection | Ensure that the machine is securely connected to a power source, and the power switch is in the correct position. |

| Threading the Needle | Properly thread the upper thread through the guides and tension discs to avoid stitching problems. |

| Bobbins and Bobbin Case | Wind the bobbin and place it correctly in the bobbin case, ensuring it rotates in the appropriate direction. |

| Needle Position | Check that the needle is installed correctly and is suitable for the type of fabric you plan to use. |

| Presser Foot | Make sure the presser foot is attached properly and adjust it according to the thickness of your fabric. |

By completing these steps, you’ll be well on your way to starting your first project with confidence. Proper setup is crucial to ensuring smooth operation and avoiding common beginner pitfalls.

Setting Up Your Sewing Machine

Before diving into your first project, it’s essential to prepare your machine correctly. Ensuring proper setup will save time and prevent common issues during sewing. This section will guide you through the fundamental steps to get your equipment ready for use, allowing you to start your creative journey smoothly and efficiently.

Unboxing and Initial Inspection: Begin by carefully unpacking the machine and checking for all necessary components. Verify that nothing is damaged and that all parts are included in the packaging.

Placing the Machine: Position the machine on a stable, flat surface with sufficient lighting. Make sure there is enough room around it for your fabric to move freely without obstructions.

Connecting the Power Supply: Plug the machine into a power outlet, ensuring the cord is out of the way to avoid tripping hazards. Confirm that the power switch is off before connecting the machine to the power source.

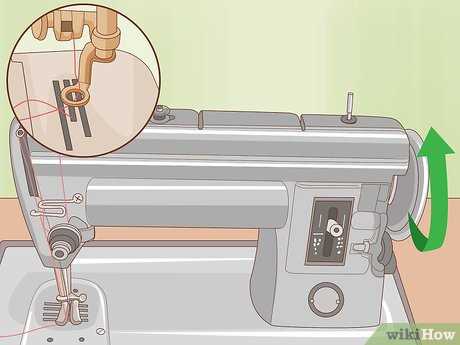

Threading the Machine: Familiarize yourself with the threading path. Proper threading is crucial for smooth operation. Follow the designated path carefully, making sure the thread passes through all necessary guides and tension mechanisms.

Inserting the Needle: Check that the needle is correctly installed and not bent or damaged. The needle should be inserted with the flat side facing the designated direction, ensuring it is pushed all the way up into the needle clamp.

Installing the Bobbin: Load the bobbin correctly in its case and place it in the designated compartment. Ensure the bobbin thread is properly threaded according to the machine’s specific requirements.

Testing the Setup: Before starting your project, run a few test stitches on a scrap piece of fabric. This will help confirm that the machine is threaded correctly and that the tension settings are adjusted appropriately for your fabric type.

Once these steps are complete, your machine will be ready for your sewing projects. Proper setup is key to achieving high-quality results and enjoying a trouble-free sewing experience.

Understanding Basic Stitch Functions

Mastering the fundamental functions of sewing machine stitches is essential for achieving a variety of sewing projects. These features allow you to customize your work, ensuring that the fabric is handled appropriately and the desired result is achieved. By understanding these stitch functions, you can create more durable seams, decorative patterns, and professional finishes.

Key Stitch Types

Different stitch types serve specific purposes, from joining fabrics to embellishing them. Below is an overview of the most common types and their primary uses:

| Stitch Type | Description | Common Uses |

|---|---|---|

| Straight Stitch | A basic, versatile stitch that creates a strong, straight line. | Seams, topstitching, hemming |

| Zigzag Stitch | A stitch that forms a zigzag pattern, ideal for stretch fabrics. | Finishing edges, appliqué, elastic insertion |

| Buttonhole Stitch | A specialized stitch for creating buttonholes. | Buttonholes, securing buttons |

| Blind Hem Stitch | A nearly invisible stitch used for hemming. | Hemming garments, curtains |

| Overcasting Stitch | A stitch that wraps around the edge of the fabric to prevent fraying. | Seam finishing, raw edge protection |

Adjusting Stitch Length and Width

Adjusting the length and width of your stitches can significantly impact the outcome of your sewing project. Longer stitches are typically used for basting and gathering, while shorter stitches are ideal for fine seams and detail work. Similarly, adjusting the width is crucial when working with zigzag stitches, where a broader width may be necessary for securing fabric edges or creating bold decorative elements.

How to Thread the Machine Properly

Threading your sewing equipment correctly is essential for smooth and efficient operation. This section will guide you through the steps required to prepare your machine for stitching, ensuring that everything is set up correctly and ready to use.

Preparing the Thread

- Place the spool of thread on the spool pin located on the top of the machine.

- Ensure that the spool is secured with a spool cap to prevent it from sliding off.

- Pull the end of the thread towards you, making sure it flows smoothly without any tangles.

Threading the Path

- Guide the thread through the first thread guide, usually located near the spool pin.

- Pull the thread down towards the tension mechanism and pass it between the tension discs.

- Next, bring the thread up through the take-up lever, ensuring it snaps into place.

- Continue to pull the thread downwards, guiding it through the remaining thread guides.

- Finally, thread the needle from front to back, leaving a small tail of thread.

After threading, make sure the thread flows smoothly and is properly positioned before starting to sew. A correctly threaded machine will help ensure consistent and even stitching.

Troubleshooting Common Issues

When using a sewing machine, you may encounter various challenges that can interrupt your work. Understanding how to identify and resolve these issues quickly can help maintain the flow of your projects and ensure high-quality results. Below, we explore some typical problems and provide guidance on how to address them effectively.

Thread Breakage: If the thread keeps breaking, check if the thread is properly threaded through the machine. Ensure the tension is not too tight and that the thread spool is placed correctly. Also, consider using a high-quality thread that matches the needle size.

Skipped Stitches: Skipped stitches may occur if the needle is bent, dull, or incorrectly inserted. Replace the needle and ensure it is the appropriate type and size for the fabric being sewn. Adjusting the thread tension might also help.

Fabric Jamming: If the fabric is getting stuck under the needle plate, it could be due to incorrect threading or improper fabric handling. Make sure the fabric is placed correctly, and double-check the threading process. Cleaning the machine’s bobbin area to remove lint or debris might also prevent jams.

Uneven Stitches: Uneven stitching can result from inconsistent fabric feed or incorrect tension settings. Verify that the fabric is being fed smoothly and that the presser foot is applying adequate pressure. Adjusting the tension and ensuring the machine is well-maintained will also help achieve even stitches.

Machine Not Running: If the machine refuses to operate, inspect the power connection and ensure the machine is correctly plugged in. Check the foot pedal connection and confirm that all settings are properly adjusted. If the problem persists, a professional service may be required.

By addressing these common issues promptly, you can minimize disruptions and enjoy a smoother sewing experience. Regular maintenance and proper machine care are essential for long-term performance.

Maintaining Your Sewing Machine

Proper upkeep of your sewing machine is essential to ensure its longevity and reliable performance. Regular maintenance helps prevent mechanical issues, keeping your device in optimal working condition. This section covers essential care practices to keep your machine running smoothly and efficiently.

Regular Cleaning

Frequent cleaning is crucial for the smooth operation of your machine. Dust, lint, and fabric fibers can accumulate in various parts, leading to jams and other problems. Start by unplugging the machine and removing the needle and presser foot. Use a small brush to clean around the bobbin case, feed dogs, and other accessible areas. Avoid using compressed air as it can push debris further into the machine. Instead, gently brush away the particles, ensuring all areas are clear.

Lubrication

Proper lubrication reduces friction in the moving parts of your machine, preventing wear and tear. Consult your machine’s guide to determine where and how often to apply oil. Use only the recommended type of oil and apply it sparingly to the designated points. After oiling, run the machine for a few minutes to distribute the lubricant evenly. Regular lubrication keeps your machine running smoothly and quietly.

By consistently cleaning and lubricating your sewing machine, you not only extend its lifespan but also enhance its performance, allowing you to complete your sewing projects with ease and precision.