In this guide, we delve into the intricacies of operating a popular brand of textile apparatus. This resource is designed to help users navigate through the various functions and features of their device, ensuring efficient use and optimal results. With detailed explanations and practical advice, we aim to enhance your proficiency with this essential tool.

The following sections will provide insights into the core functionalities, maintenance practices, and troubleshooting tips. Whether you’re a novice or experienced user, this guide offers valuable information to assist in mastering your equipment. Embrace the knowledge presented to maximize the benefits of your textile tool.

Understanding Your Jaguar Mate Sewing Machine

Grasping the essence of your new textile apparatus involves recognizing its core features and operational principles. This section provides a comprehensive overview to help you familiarize yourself with the essentials of your new equipment, ensuring a smooth start to your creative journey.

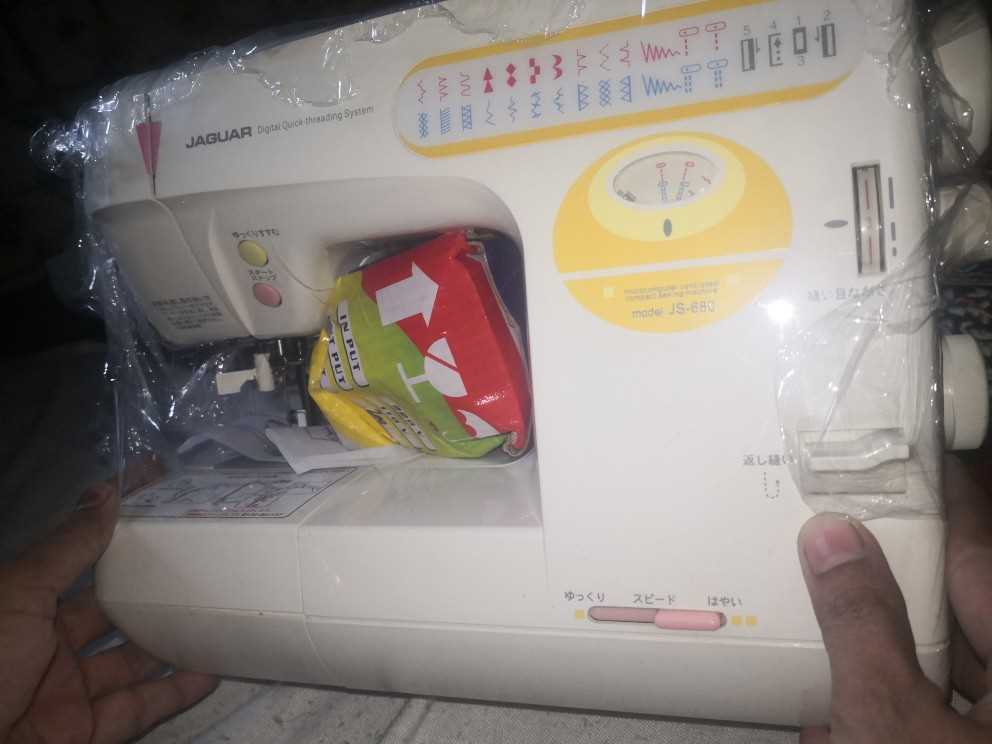

Key Components and Their Functions

Your device comprises several crucial elements that contribute to its overall functionality. Familiarize yourself with each part’s role, from the primary controls to the various attachments that enhance its versatility. Understanding these components will enable you to use the apparatus more effectively and troubleshoot any issues that may arise.

Basic Operations and Settings

Learn how to set up your apparatus for optimal performance by adjusting basic settings. This includes selecting the appropriate configurations for different tasks and understanding how to operate the device with ease. Properly adjusting these settings will help you achieve the best results in your projects.

Basic Features and Functions

This section explores the essential attributes and capabilities of a popular textile work tool, emphasizing its various functionalities designed to enhance ease of use and versatility in crafting tasks. It provides a comprehensive overview of the primary components that facilitate different types of fabric manipulation and customization.

Main Components

| Component | Description |

|---|---|

| Needle Mechanism | Allows precise stitching and adjustment to accommodate various types of threads and fabrics. |

| Thread Tension Control | Regulates the tightness of the thread for consistent stitching quality and performance. |

| Stitch Selector | Provides options for different stitch patterns to suit various sewing projects and techniques. |

Functional Capabilities

These tools come equipped with multiple features to streamline the crafting process, including automatic threading, adjustable stitch lengths, and programmable patterns. These functionalities aim to improve efficiency and precision, making complex tasks more manageable.

Setting Up Your Sewing Machine

Getting started with your new equipment involves a series of essential steps to ensure it operates smoothly. Begin by unpacking all components and verifying their completeness. Proper assembly and configuration are crucial for optimal performance and ease of use.

Follow these steps to prepare your device:

| Step | Description |

|---|---|

| 1 | Place the unit on a stable surface, ensuring it is level and secure. |

| 2 | Assemble the different parts according to the provided guidelines, connecting all necessary components. |

| 3 | Install the power supply and connect it to a suitable outlet, making sure all connections are tight and secure. |

| 4 | Load the thread and set up the needle, following the specific instructions for threading and placement. |

| 5 | Perform a test run to verify that everything is functioning correctly and make any necessary adjustments. |

Threading and Bobbin Installation

Proper preparation of the thread and bobbin is crucial for smooth and effective operation of your stitching device. Ensuring these components are correctly set up will enhance the performance and longevity of your equipment.

- Begin by threading the upper thread through the designated guides and tension mechanisms. Ensure the thread is correctly aligned and free of tangles.

- Place the bobbin in its designated compartment. Confirm that it is positioned properly and that the thread feeds in the correct direction.

- Check that both the upper thread and the bobbin thread are correctly threaded through the respective take-up lever and needle. This step is essential for proper stitching function.

- Finally, manually rotate the handwheel to ensure the needle catches the thread from the bobbin and forms a stitch. Adjust as needed for optimal performance.

Operating Stitches and Controls

Understanding how to utilize various stitching options and manage settings is crucial for efficient fabric manipulation. This section provides insights into effectively navigating the different stitch types and adjusting the relevant controls to enhance your sewing experience.

Exploring Stitch Types

Each fabric manipulation task requires specific stitch configurations. Familiarize yourself with the available stitch patterns and their purposes. From basic stitches for simple seams to more complex options for decorative elements, each type serves a distinct function. Ensuring you select the appropriate stitch will lead to better results and a more enjoyable process.

Adjusting Controls

Proper adjustment of controls allows for precise execution of stitches. Learn to fine-tune settings such as stitch length, width, and tension. Mastery of these controls ensures that your fabric is handled with the desired precision, enhancing both the functionality and appearance of your work.

Maintenance and Troubleshooting Tips

Proper upkeep and problem-solving are essential to ensure the longevity and efficient performance of your crafting device. Regular attention to these areas can prevent many common issues and extend the life of your equipment.

For optimal care, follow these guidelines:

- Regular Cleaning: Dust and debris can accumulate and interfere with performance. Clean the components regularly using a soft brush or cloth. Ensure that the needle area, feed dogs, and bobbin case are free from lint and other particles.

- Oil Application: Lubrication is crucial for smooth operation. Apply oil sparingly to the moving parts as per the device’s specifications. Over-oiling can lead to problems, so follow the recommended intervals and amounts.

- Needle Care: Replace needles that become dull or damaged. A worn needle can cause skipped stitches or fabric snags. Use the appropriate needle type for your fabric and task.

- Thread Tension Adjustment: Incorrect thread tension can lead to uneven stitches or thread breakage. Adjust the tension settings according to the type of fabric and thread being used.

- Bobbin Management: Ensure the bobbin is correctly wound and inserted. A misaligned or improperly wound bobbin can cause stitching issues.

In case of operational issues, consider the following troubleshooting steps:

- Machine Won’t Start: Check the power supply and connections. Ensure the plug is properly connected and the power switch is turned on.

- Stitching Problems: If stitches are uneven or missing, verify the needle and thread tension settings. Also, check for any obstruction in the threading path.

- Thread Jamming: Remove the fabric and bobbin, and inspect for thread tangles. Clear any obstructions and re-thread the device carefully.

- Unusual Noise: If you hear unusual sounds, it could indicate a problem with the internal mechanisms. Turn off the device and inspect for any visible issues or loose parts.

Following these maintenance and troubleshooting tips will help you keep your crafting equipment in excellent condition and resolve common issues effectively.

Additional Accessories and Their Uses

Enhancing your crafting experience often involves incorporating various supplementary tools designed to expand the capabilities of your equipment. These extra components not only streamline your workflow but also enable you to achieve a greater range of tasks with precision and ease.

- Presser Feet: Different types of presser feet are available for specialized tasks. For instance, a zipper foot is essential for sewing zippers, while a walking foot assists in stitching multiple layers of fabric evenly.

- Needles: Various needle types are suited for different fabrics and stitching requirements. Using the correct needle can significantly affect the quality of your work, making it crucial to select the appropriate type for your material.

- Bobbin Cases: These are used to hold the bobbin thread and can vary in design. Some bobbin cases are adjustable to improve tension control, which can enhance stitch quality and consistency.

- Extension Tables: Providing additional workspace, extension tables are particularly useful for handling larger projects. They offer extra support and stability for fabrics, making it easier to manage and maneuver them during the crafting process.

- Feet Attachments: Specialized attachments, such as those for quilting or embroidery, can add versatility to your tool. These attachments are designed to facilitate specific techniques and provide improved functionality for specialized tasks.

Utilizing these accessories effectively can transform your crafting endeavors, providing you with enhanced capabilities and improved results. By integrating the right tools, you can tailor your experience to meet various creative needs and achieve professional-quality outcomes.