In the world of intricate marking and etching, mastering the nuances of advanced engraving machinery is essential for achieving optimal results. This guide delves into the intricacies of a sophisticated device designed to elevate your engraving capabilities. Whether you are a seasoned professional or a newcomer to the field, understanding the functionalities and operational aspects of this equipment can significantly enhance your work quality and efficiency.

Our exploration covers the essential aspects of setting up, operating, and maintaining this advanced engraver. Through detailed explanations and practical tips, we aim to equip you with the knowledge necessary to harness the full potential of the machine. By familiarizing yourself with its features and learning the best practices, you can ensure precise and consistent outcomes in your engraving projects.

We invite you to delve into this guide, which is crafted to provide clear and actionable insights. Embrace the opportunity to refine your skills and expand your capabilities with this indispensable tool, transforming your approach to detailed and professional marking tasks.

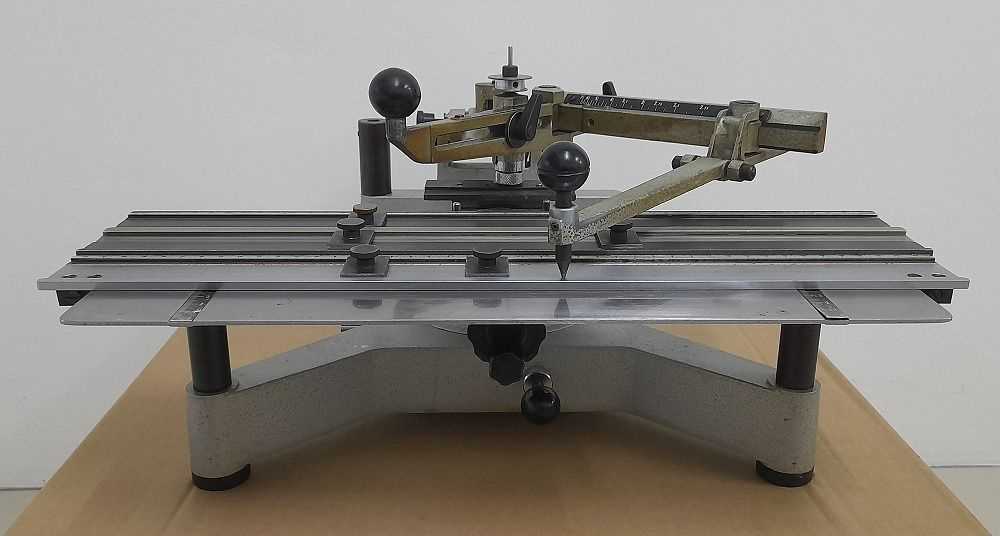

Understanding the IM3 Features

In this section, we will explore the various functionalities and attributes that make this engraving system a valuable tool for precision marking. The device boasts an array of features designed to enhance the engraving process, offering both flexibility and efficiency for users across different applications. Whether you are a novice or a seasoned professional, understanding these capabilities will help you leverage the equipment to its fullest potential.

Key Capabilities

One of the standout attributes of this system is its advanced control interface. It provides users with the ability to fine-tune settings and parameters to match specific engraving requirements. The intuitive design ensures that even those unfamiliar with intricate machinery can quickly adapt and achieve precise results. Additionally, the device supports various materials, making it versatile for a range of tasks from simple labels to complex designs.

Efficiency and Precision

Another significant feature is its efficiency in handling tasks with high accuracy. The system incorporates sophisticated technology that ensures consistent results while minimizing errors. This reliability is crucial for maintaining high standards in production and customization. Furthermore, the robust build quality and engineering contribute to its long-term durability, ensuring that it remains a dependable tool in any workshop or production environment.

Setting Up Your Gravograph IM3

Getting your engraving machine ready for operation involves several essential steps to ensure optimal performance and accurate results. Proper setup is crucial for achieving the best possible outcomes from your equipment, as well as for maintaining its longevity. Follow the instructions below to prepare your device efficiently and effectively.

Unpacking and Initial Inspection

Before beginning the setup process, carefully unpack the machine and inspect all components to ensure nothing is damaged or missing. Follow these steps:

- Remove the machine from its packaging and place it on a stable, level surface.

- Check for any visible signs of damage that may have occurred during shipping.

- Verify that all included parts and accessories are present according to the parts list.

- Keep the packaging materials in case you need to store or transport the machine later.

Connecting and Calibrating the Machine

Once you have inspected the machine, proceed with connecting and calibrating it. This step ensures that all components are properly aligned and functioning correctly. Follow these instructions:

- Connect the power cord to the machine and plug it into a suitable electrical outlet.

- Turn on the machine and allow it to complete its startup routine.

- Connect the machine to your computer using the provided interface cable.

- Install any necessary drivers or software as instructed by the manufacturer.

- Perform a basic calibration to align the engraving head and ensure accurate operation. Refer to the calibration section in your equipment’s guide for detailed steps.

With these steps completed, your engraving machine should be ready for use. Ensure that you follow any additional setup instructions specific to your model to achieve the best results.

Basic Operation Instructions

Understanding how to operate your engraving machine is crucial for achieving accurate and high-quality results. This section will guide you through the essential steps required to get your device up and running efficiently. Follow these guidelines to ensure smooth operation and optimal performance.

Begin by setting up the machine in a stable and level area. Ensure that it is connected to a power source and that all cables are securely attached. Once the machine is properly positioned, you can proceed with the following steps:

- Power On: Turn on the machine using the main power switch. Wait for the system to complete its initialization process before proceeding.

- Load Material: Place the material you wish to engrave onto the work surface. Adjust the material’s position to ensure it is aligned correctly with the engraving area.

- Adjust Settings: Configure the machine settings according to the requirements of your project. This may include parameters such as engraving depth, speed, and type of cut.

- Run Test: Perform a test run to verify that the settings are correct and that the material is properly aligned. Make any necessary adjustments before starting the final engraving.

- Start Engraving: Once you are satisfied with the test run, initiate the engraving process. Monitor the machine to ensure that it is operating correctly and that the engraving is proceeding as expected.

- Power Off: After the engraving is complete, turn off the machine and disconnect it from the power source. Remove the engraved material from the work surface.

By following these fundamental steps, you will be able to operate your engraving machine efficiently and achieve high-quality results in your projects.

Maintenance Tips and Troubleshooting

Regular upkeep and prompt resolution of issues are crucial for the optimal performance of any equipment. This section provides essential guidelines to ensure that your device remains in top condition and common problems are addressed efficiently. By adhering to these practices, you can enhance longevity and reliability, minimizing downtime and maximizing productivity.

Routine Maintenance Guidelines

- Keep the device clean by regularly dusting off surfaces and components. Use a soft, lint-free cloth to avoid scratching sensitive areas.

- Inspect and clean the lens or cutting head as per the manufacturer’s recommendations. Debris buildup can affect precision and performance.

- Check and tighten all connections and screws to prevent vibrations and misalignments that could impact operation.

- Ensure that all moving parts are properly lubricated according to the maintenance schedule. This helps to reduce friction and wear.

- Verify that the software and firmware are up-to-date to benefit from the latest features and fixes.

Troubleshooting Common Issues

- Device Not Powering On:

- Check the power supply and ensure that the device is properly connected to a functioning outlet.

- Inspect the power cord for any visible damage and replace if necessary.

- Examine the fuse or circuit breaker to ensure there are no electrical issues.

- Inconsistent Performance:

- Verify that all calibration settings are correct and have not been altered.

- Ensure that the material being processed meets the recommended specifications.

- Check for any obstructions or misalignments in the moving parts.

- Error Messages:

- Refer to the device’s error code reference to identify the specific issue.

- Follow the suggested troubleshooting steps provided for the particular error code.

- If the issue persists, consider contacting technical support for further assistance.

By following these maintenance tips and addressing issues promptly, you can ensure a smoother operation and longer lifespan for your equipment. Regular checks and prompt action on potential problems can save time and reduce the need for costly repairs.

Advanced Techniques for Efficient Use

Mastering the nuances of engraving systems involves more than just basic operation. To truly excel, one must delve into advanced strategies that optimize both performance and precision. This section will explore sophisticated methods designed to enhance productivity and accuracy, offering insights that go beyond fundamental practices.

Fine-Tuning Parameters: Understanding and adjusting the machine’s settings can make a significant difference. Tailoring parameters such as speed, power, and resolution to specific materials and tasks will ensure superior results. Experiment with different settings to find the ideal balance for each unique application.

Material Considerations: Different substrates react uniquely to engraving processes. By familiarizing yourself with the characteristics of various materials, you can select appropriate techniques and tools to achieve the best outcomes. Conduct tests and keep a log of results to refine your approach.

Maintaining Equipment: Regular maintenance is crucial for consistent performance. Ensure that all components are clean and functioning correctly. Regularly calibrate the system and replace worn parts to prevent issues and extend the lifespan of your equipment.

Utilizing Software Capabilities: Advanced software features can greatly enhance your capabilities. Take advantage of available design and editing tools to create complex patterns and designs with greater ease. Explore tutorials and guides to fully leverage these software functionalities.

Workflow Optimization: Streamline your workflow by organizing tasks and minimizing downtime. Develop a systematic approach to preparing materials, setting up jobs, and processing outputs. Efficient organization and time management will contribute to overall productivity.

By incorporating these advanced techniques into your routine, you can elevate your engraving practices to a higher level of efficiency and quality.

Safety Precautions and Best Practices

Ensuring safety and following best practices is crucial when operating any complex equipment. Proper precautions not only safeguard the user but also enhance the longevity and effectiveness of the machinery. Adhering to these guidelines helps in minimizing risks and optimizing performance.

General Safety Guidelines

- Always wear appropriate personal protective equipment (PPE) such as safety glasses and gloves.

- Keep the work area clean and free of obstructions to prevent accidents.

- Ensure that all safety guards and covers are in place before operating the machine.

- Read and understand all warning labels and safety instructions provided by the manufacturer.

Operational Best Practices

- Before starting, check all connections and components to ensure they are properly installed and secured.

- Regularly inspect and maintain the equipment according to the recommended schedule to prevent malfunctions.

- Use the machine only for its intended purposes and follow the operational procedures as outlined.

- Report any malfunctions or irregularities immediately and do not attempt to use the machine until it has been repaired.