In the realm of electrical diagnostics, a fundamental device stands out for its versatility and precision. This tool is essential for anyone involved in the measurement of electrical parameters, offering a wide range of functionalities that make it indispensable in both professional and personal settings. Whether you are troubleshooting, testing, or calibrating various components, having a clear understanding of how to operate this instrument effectively is crucial.

For those new to this equipment or seeking to refine their expertise, a thorough grasp of its features and operational techniques can significantly enhance the accuracy of your work. This guide aims to provide comprehensive insights into the effective use of this measurement device, ensuring you can fully leverage its capabilities. With detailed instructions and practical tips, you will be equipped to handle various measurement tasks with confidence and precision.

By familiarizing yourself with the nuances of this instrument, you can optimize your approach to electrical testing and maintenance. The following sections will delve into the specific functionalities and operational guidelines, helping you navigate through the complexities of this essential tool and achieve reliable results in your electrical endeavors.

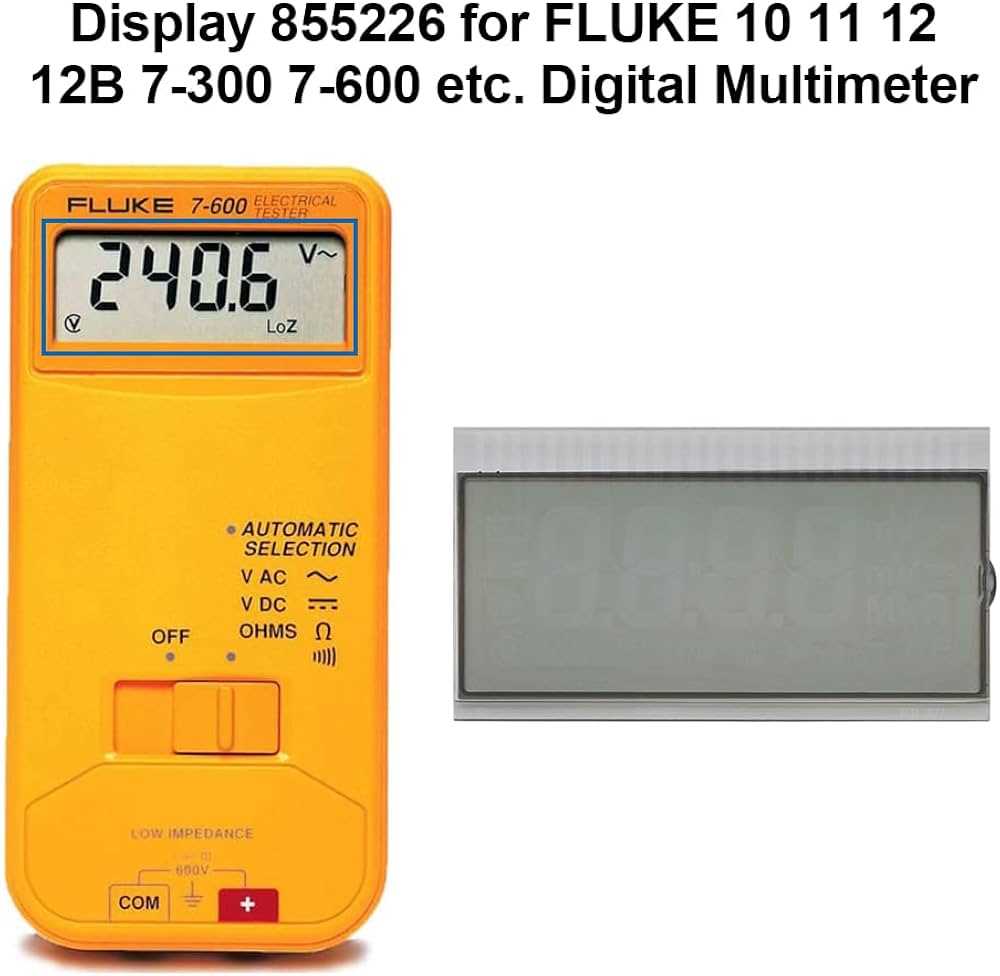

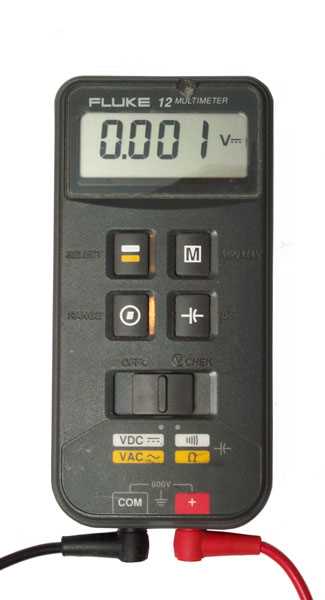

Overview of Fluke 12 Multimeter Features

This section provides an in-depth look at the essential characteristics and functionalities of a compact and reliable measuring device designed for a variety of electrical tasks. The device offers a range of features tailored to meet both basic and advanced needs, making it suitable for professionals and hobbyists alike. Understanding these features helps users utilize the tool more effectively and efficiently.

Key Functions and Capabilities

Among its notable attributes, this device includes the ability to measure voltage, current, and resistance with precision. It is equipped with a digital display that provides clear and accurate readings, ensuring ease of use even in challenging conditions. Additionally, the tool features a rotary switch that allows users to easily select different measurement modes.

Additional Features

Beyond basic measurements, this instrument comes with several advanced functions. It includes auto-ranging capabilities, which automatically adjusts the measurement range to provide accurate readings without manual adjustments. The data hold function allows users to freeze the displayed value for easier recording and analysis. Furthermore, the device is designed with a rugged housing to withstand harsh environments and ensure longevity.

Basic Operation and Functions

Understanding how to use a measuring device effectively requires familiarity with its core functions and operations. This section provides a comprehensive overview of the primary features and how to utilize them for accurate measurements. Knowing how to navigate through these functionalities ensures that users can obtain precise readings for various electrical parameters.

Powering On and Off

To start using the device, press the power button located on the front panel. This action activates the device and prepares it for use. To turn it off, press and hold the power button until the screen goes dark. Properly turning off the device helps conserve battery life and ensures its longevity.

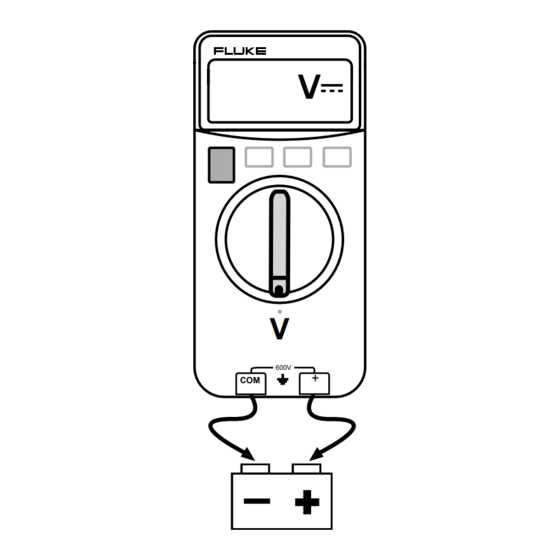

Measuring Electrical Parameters

The device is capable of measuring several electrical properties. Each function can be selected via the rotary dial or button interface. Below is a summary of the key measurement functions and their uses:

| Function | Description |

|---|---|

| Voltage | Measures the electrical potential difference between two points. Suitable for both AC and DC measurements. |

| Current | Measures the flow of electric charge through a circuit. Available in both AC and DC modes. |

| Resistance | Assesses the opposition to the flow of current in a component or circuit. |

| Continuity | Checks if there is a complete path for current flow, often used to test connections and cables. |

Select the desired function by rotating the dial or pressing the corresponding button. Ensure the device is properly connected to the circuit or component under test to obtain accurate readings. Following these basic operations allows users to effectively utilize the device for various electrical testing needs.

Safety Precautions and Guidelines

When using electronic measuring devices, ensuring safety is paramount to prevent accidents and ensure accurate results. Adhering to proper safety protocols not only safeguards the user but also maintains the integrity of the equipment. This section provides essential recommendations to follow when operating these tools.

General Safety Rules

Always read and understand the operating procedures before using the device. Make sure to inspect the instrument and its components regularly for any signs of damage or wear. Do not use the device if it is damaged or appears to be malfunctioning. Keep the instrument away from moisture and avoid using it in wet or damp environments to prevent electrical hazards.

Handling and Operation

When taking measurements, ensure the device is properly set to the correct function and range for the task. Use the appropriate test leads and connections for the measurement type. Never touch the exposed metal parts of the probes while the device is active, as this could result in electric shock. Additionally, always discharge capacitors before measuring them to avoid potential harm or damage.

By following these safety precautions, you can minimize risks and ensure a safe and effective operation of your measuring equipment.

Using Measurement Modes Effectively

Understanding how to utilize various measurement functions is crucial for achieving accurate results in electrical diagnostics and troubleshooting. Each function on a device offers specific capabilities tailored to different types of electrical measurements. Mastering these functions ensures that users can apply the most appropriate settings for their tasks, leading to more precise and reliable outcomes.

When selecting a measurement mode, consider the specific requirements of your task. For instance, when assessing voltage, choosing between AC and DC settings can significantly impact the accuracy of your readings. Similarly, when measuring resistance or continuity, ensure that the device is set to the correct mode to avoid erroneous results and potential damage to the equipment.

Additionally, familiarize yourself with the range options available for each mode. Using the appropriate range setting can enhance the accuracy of your measurements and prevent overload conditions. For tasks requiring high precision, such as calibrating circuits or troubleshooting sensitive components, selecting the correct range and mode is essential for obtaining valid results.

Regular practice and familiarity with each measurement function will improve your proficiency and confidence in handling various electrical testing scenarios. By understanding the strengths and limitations of each mode, you can make more informed decisions and perform measurements more effectively.

Understanding Display Readings and Indicators

Interpreting the values shown on your device’s display and recognizing various indicators are essential skills for accurate measurement and effective troubleshooting. The screen provides crucial information about the electrical characteristics of the circuit or component you are examining. By familiarizing yourself with these readings and symbols, you can make informed decisions and diagnose issues more efficiently.

Types of Display Readings

The display typically shows different types of measurements, including voltage, current, and resistance. Each measurement is represented in numerical form, often accompanied by a unit of measure such as volts (V), amperes (A), or ohms (Ω). For instance, a reading of 12.5 V indicates a voltage of 12.5 volts across the circuit. Understanding the significance of these values helps in assessing the performance and condition of electrical components.

Common Indicators and Symbols

Besides numerical readings, the display might feature various symbols and indicators. These include signs for overload conditions, low battery warnings, and specific measurement modes. Overload indicators alert you when the input exceeds the device’s measuring range, while low battery symbols signal that the power source needs replacement. Familiarity with these symbols ensures that you address potential issues promptly and maintain accurate readings.

By mastering these display elements and indicators, you can effectively use your device for a wide range of electrical tasks, enhancing both safety and precision in your work.

Maintenance and Calibration Tips

Keeping your measuring device in optimal condition is essential for ensuring accurate and reliable readings. Regular upkeep and proper adjustments can prevent errors and extend the lifespan of your equipment. Adhering to these practices will help maintain precision and performance over time.

Routine Maintenance

Perform routine checks to keep your device functioning correctly. Here are some essential maintenance tasks:

| Task | Frequency | Description |

|---|---|---|

| Inspect for Physical Damage | Monthly | Check for any visible signs of wear or damage to the casing and display. |

| Clean the Contacts | Every 3 Months | Ensure the probes and terminals are free of dirt and oxidation. |

| Verify Battery Condition | Monthly | Check battery levels and replace batteries as needed to avoid unexpected shutdowns. |

Calibration Procedures

Regular calibration ensures that your instrument provides accurate measurements. Follow these steps for proper calibration:

| Step | Description | Frequency |

|---|---|---|

| Prepare Calibration Equipment | Gather the necessary reference standards and calibration tools. | Before Each Calibration |

| Perform Zero Calibration | Set the device to zero using the reference standards. | Quarterly |

| Adjust Calibration Settings | Compare readings with known values and adjust settings as needed. | Quarterly |

By adhering to these maintenance and calibration tips, you will ensure the long-term accuracy and reliability of your measuring instrument.

Common Troubleshooting Techniques

When dealing with electronic measuring devices, it’s essential to have a set of reliable methods for identifying and resolving issues. These techniques help ensure accurate readings and prolong the lifespan of your equipment. By following a systematic approach, you can efficiently address common problems that may arise during use.

Checking for Proper Functionality

One of the first steps in troubleshooting is to verify that the device is operating correctly. Ensure that the battery is fully charged and properly installed. If the readings are inconsistent or nonexistent, replacing the battery is a simple yet effective solution. Additionally, inspect the probes and connections for any signs of damage or wear. A loose or broken probe can lead to inaccurate measurements.

Calibration and Accuracy Verification

Another important aspect of maintenance is verifying the accuracy of your measurements. Regular calibration is crucial to ensure precise readings. Use known reference values to test the device’s accuracy. If discrepancies are found, consult the calibration procedures and adjust as necessary. Maintaining accurate calibration helps in obtaining reliable results and preventing measurement errors.