In the realm of home improvement and construction, having the right equipment is crucial for achieving accurate results. Among the essential tools for locating hidden structural elements within walls is a reliable detection device. This guide aims to provide a thorough overview of how to effectively utilize this particular device, ensuring you can confidently and accurately find what you need behind the surface.

Understanding the proper usage of your detection tool is key to optimizing its performance. This includes learning how to operate it correctly, interpreting its signals, and maintaining it for long-term reliability. By mastering these aspects, you’ll enhance your ability to carry out various tasks with precision, whether you’re installing fixtures, hanging heavy objects, or performing renovations.

We will walk you through the detailed steps necessary for operating your detection device, offering insights into its features and functionality. With this guide, you will be well-equipped to make the most of your tool and achieve professional-grade results in your projects.

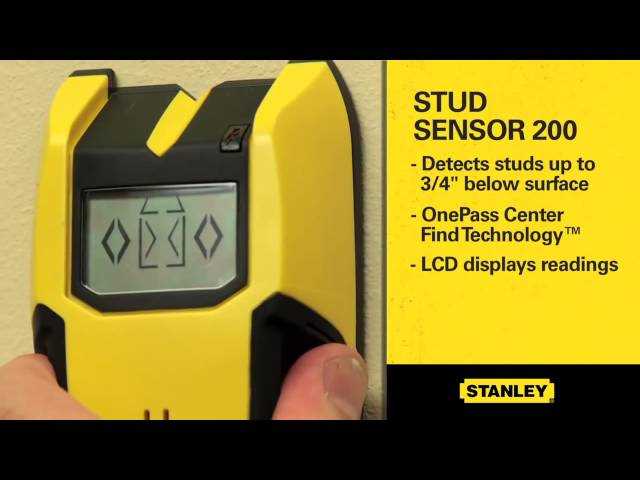

Overview of Stanley Stud Sensor 200

This section provides an overview of a device designed to locate underlying structural elements within walls. The primary purpose of this tool is to assist users in identifying hidden components behind surfaces, which is particularly useful for tasks such as drilling or mounting fixtures. The equipment is known for its efficiency in detecting both wood and metal supports, making it a versatile addition to any toolkit.

Key Features

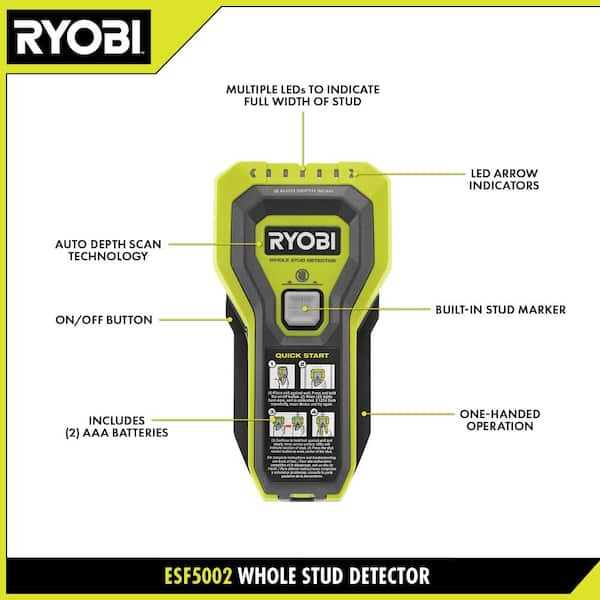

The tool boasts several notable features that enhance its functionality. Users can expect accurate detection of various materials, a clear display for easy reading, and intuitive operation. Its design emphasizes user-friendliness and precision, ensuring that both professionals and DIY enthusiasts can achieve reliable results.

How It Works

This device operates by using advanced technology to scan the wall and identify underlying objects. It typically features a digital display or indicator lights that provide real-time feedback on the detected elements. Users simply need to move the device across the wall surface, and it will alert them to the presence of hidden supports.

| Feature | Description |

|---|---|

| Detection Capabilities | Accurately locates wooden and metal supports |

| Display | Clear and easy-to-read digital or light indicators |

| Ease of Use | User-friendly with simple operation |

| Applications | Ideal for drilling, mounting, and other tasks requiring knowledge of wall structure |

How to Install the Sensor

Setting up a detection device involves a straightforward process that ensures accurate readings and optimal performance. Following these steps will help you efficiently position and secure the equipment for reliable operation.

Preparation

Begin by gathering the necessary tools and materials. Make sure you have a power source or batteries, a level for alignment, and any mounting hardware included with the unit. Identify the location where you plan to install the device, ensuring it aligns with the intended use and provides clear access for easy adjustment.

Installation Steps

First, choose the appropriate spot for installation, typically on a wall or similar surface. If the device requires calibration, follow the manufacturer’s guidelines to set it up accurately. Mount the unit securely using the provided screws or adhesive strips, depending on the surface and device specifications. After mounting, verify that the device is level and properly aligned with the surface to ensure precise functionality.

Finally, power up the unit and test its operation to confirm that it is working as expected. Make any necessary adjustments based on your initial test to fine-tune the device for optimal performance.

Understanding Sensor Calibration

Calibration is a crucial process that ensures the accuracy and reliability of a detection device. It involves adjusting the equipment to align with standard measurement values or known benchmarks. This procedure is essential to guarantee that the readings produced by the device reflect true conditions and are free from significant errors or inconsistencies.

Why Calibration Matters

Proper calibration of a detection tool ensures that it performs accurately, reducing the likelihood of incorrect readings that could lead to faulty conclusions or inadequate results. Without calibration, there is a risk of measurement drift over time, which can affect the quality of work and safety in various applications.

Steps in the Calibration Process

To effectively calibrate a detection device, follow these general steps:

- Preparation: Gather all necessary tools and ensure the device is clean and in good working condition.

- Benchmarking: Compare the device’s readings against a known standard or reference value.

- Adjustment: Modify the device settings to align with the standard measurements.

- Verification: Test the device again to confirm that it now provides accurate results.

Regular calibration is vital for maintaining the precision of your device, ensuring it operates correctly and consistently. Following these steps will help in achieving reliable performance and extending the lifespan of the equipment.

Interpreting Detection Results

Understanding the outcomes from your detection tool is crucial for accurate and effective use. The device’s feedback will guide you in assessing the presence of materials behind surfaces. Proper interpretation of these results will ensure that you make informed decisions regarding your drilling or installation tasks.

Common Detection Signals

Detection tools typically provide several types of signals to indicate different findings. Familiarize yourself with these signals to better understand what each one means:

- Indicator Light: A constant or flashing light usually signifies the presence of a material. The pattern or color may vary depending on the device.

- Audible Alerts: Beeps or other sounds often correlate with material density or proximity. The frequency or duration of the sound can provide additional clues.

- Digital Readouts: Some devices display numerical values or graphical representations to indicate material depth or type. Pay attention to these readings for precise measurements.

Interpreting Results

To accurately interpret the signals from your detection tool, consider the following steps:

- Compare Readings: Cross-reference the signals with the device’s guidelines to determine the material type. Different materials may trigger distinct signals.

- Check Depth: Ensure you understand the depth indicated by the device. This is vital for ensuring that you do not accidentally damage hidden pipes or wiring.

- Verify with Manual Testing: If possible, conduct a manual test or use another tool to verify the results. This helps in confirming the accuracy of the initial detection.

By carefully analyzing the signals and understanding their implications, you can effectively use your tool to achieve precise and reliable results in your projects.

Common Issues and Troubleshooting Tips

When using a wall detection tool, users may encounter various challenges that can impact its accuracy and effectiveness. Understanding these common problems and knowing how to address them can significantly enhance your experience and ensure reliable results.

Frequent Problems and Their Causes

One of the most common issues is incorrect readings or inconsistent performance. This can be attributed to several factors such as battery life, interference from metal objects, or incorrect calibration. Additionally, walls with unusual materials or densities may cause the tool to malfunction or provide inaccurate results.

Troubleshooting Strategies

To address these issues, first check the battery and replace it if necessary. Ensure the device is properly calibrated by following the manufacturer’s instructions. Avoid using the tool near large metal objects or electrical wiring, as these can interfere with its operation. For walls with non-standard materials, try to perform a calibration or adjust the settings if the tool allows it.

| Issue | Possible Cause | Solution |

|---|---|---|

| Inaccurate readings | Low battery | Replace the battery |

| Intermittent performance | Metal interference | Avoid metal objects |

| Calibration issues | Improper calibration | Recalibrate the tool |

| Unusual wall materials | Non-standard wall density | Adjust settings if possible |

Maintenance and Care Instructions

Proper upkeep of your device is essential to ensure its longevity and optimal performance. Regular maintenance not only extends the lifespan of the tool but also ensures its accuracy and reliability in various tasks. Adhering to a few simple guidelines will help maintain the tool in excellent working condition.

Keep it Clean: Always keep the device free from dust, debris, and moisture. Gently wipe the exterior with a soft, dry cloth. Avoid using harsh chemicals or abrasive materials that could damage the surface.

Storage: Store the tool in a dry, cool place when not in use. Avoid exposing it to extreme temperatures or direct sunlight, as these conditions could affect its performance. Ensure it is kept in a protective case or pouch to prevent accidental damage.

Battery Care: If your device uses batteries, remove them if the tool will not be used for an extended period. Store batteries in a cool, dry place and replace them with fresh ones as needed. Check battery contacts for corrosion and clean them gently if necessary.

Regular Checks: Periodically inspect the device for any signs of wear or malfunction. Ensure all components are securely attached and functional. If you notice any irregularities, consult a professional for repairs or servicing.

Calibration: Regularly calibrate the device according to the manufacturer’s recommendations to maintain accuracy. Follow the calibration process carefully to ensure reliable readings and performance.