Understanding how to properly operate your household equipment can make all the difference in the quality and efficiency of your work. This article provides a thorough overview of the setup and functionalities of a versatile crafting tool, ensuring that you maximize its potential while minimizing any frustrations during your creative process.

From basic configuration to advanced features, this guide will walk you through every step needed to fully utilize your machine. Whether you’re a novice or an experienced user, this resource aims to enhance your knowledge and help you achieve the best results possible.

Throughout the following sections, you’ll find detailed explanations, practical tips, and troubleshooting advice to ensure smooth operation. The goal is to equip you with the confidence and skills necessary to complete your projects with ease and precision.

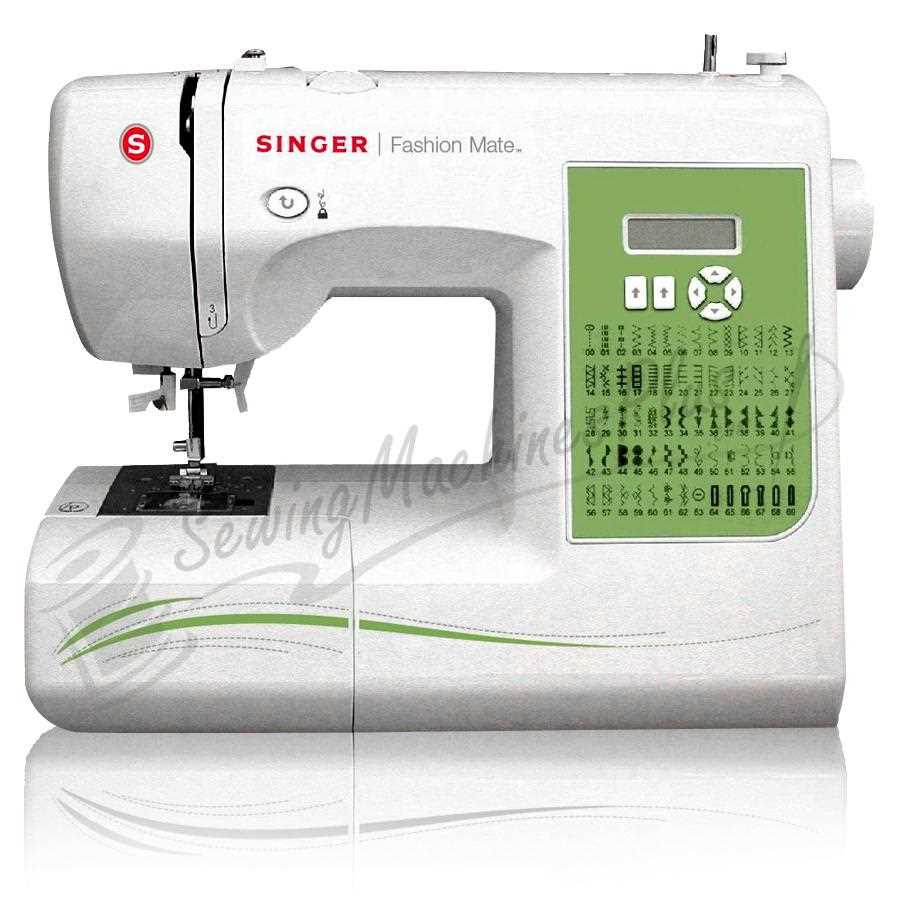

Getting Started with the Singer Sew Mate 5400

Embarking on a new project with your crafting machine can be both exciting and a bit daunting. This section will guide you through the initial steps, helping you become familiar with the essential components and basic operations of your machine.

Unpacking and Setup

Begin by carefully removing your new crafting device from its packaging. Ensure that all components are accounted for, including the power cable, foot pedal, and any accessories. Place the machine on a stable surface near a power outlet. Connect the power cord and foot pedal, making sure both are securely attached.

Basic Controls Overview

Before starting your first project, take a moment to understand the main controls. Below is a simple table outlining the primary functions:

| Control | Function |

|---|---|

| Stitch Selection Dial | Allows you to choose different stitch types based on your project needs. |

| Tension Adjustment | Regulates the tightness of the thread, essential for achieving smooth stitching. |

| Reverse Lever | Enables stitching in reverse to reinforce seams. |

| Speed Control | Adjusts the sewing speed, providing better control over your work. |

By familiarizing yourself with these controls, you’ll be better prepared to tackle your projects with confidence. As you gain more experience, these settings will become second nature, allowing you to focus on your creative process.

Key Features and Benefits Overview

This section outlines the core functionalities and advantages of the product, designed to enhance your experience and make your projects more efficient. Below is a detailed breakdown of the key aspects that contribute to its overall performance and reliability.

- Versatile Stitching Options: With a wide range of stitch types available, users can effortlessly switch between decorative, functional, and specialized stitches to meet various project needs.

- User-Friendly Interface: The intuitive control panel allows for easy selection of settings, ensuring a smooth and hassle-free operation for both beginners and advanced users.

- Enhanced Precision: The adjustable settings enable fine-tuning for different fabric types, providing consistent results with every use.

- Durable Construction: Built to last, the robust design ensures long-term use with minimal maintenance, making it a reliable choice for all kinds of creative tasks.

- Compact and Lightweight: Its portable design allows for easy storage and transport, making it convenient to use in various settings, whether at home or on the go.

- Time-Saving Features: The inclusion of automated functions, such as needle threading and buttonhole creation, significantly reduces the time and effort required for setup and execution.

These features collectively offer a balanced blend of convenience, precision, and durability, ensuring that every project is completed with professional-level results.

Threading the Needle: Step-by-Step Guide

Mastering the art of threading a needle is essential for smooth and effective machine operation. Properly threading ensures that your device runs efficiently, delivering precise stitches and reducing the chances of any issues during your projects.

Step 1: Preparing the Thread

Before you start, ensure that your machine is turned off. Select the thread that matches your fabric and load it onto the spool pin. Make sure the thread is securely placed and free of tangles.

Step 2: Guiding the Thread

Gently pull the thread from the spool, passing it through the first thread guide. Continue to guide the thread down through the tension mechanism, ensuring that it is properly seated. Then, bring the thread up to the take-up lever and pull it through.

| Step | Action |

|---|---|

| 1 | Place the thread on the spool pin. |

| 2 | Pass the thread through the first guide. |

| 3 | Guide the thread through the tension mechanism. |

| 4 | Thread the take-up lever. |

| 5 | Guide the thread down to the needle. |

| 6 | Thread the needle eye. |

Once the thread reaches the needle, carefully thread it through the eye from front to back. Pull a few inches of thread through the needle to ensure you have enough slack. Your machine is now ready for operation.

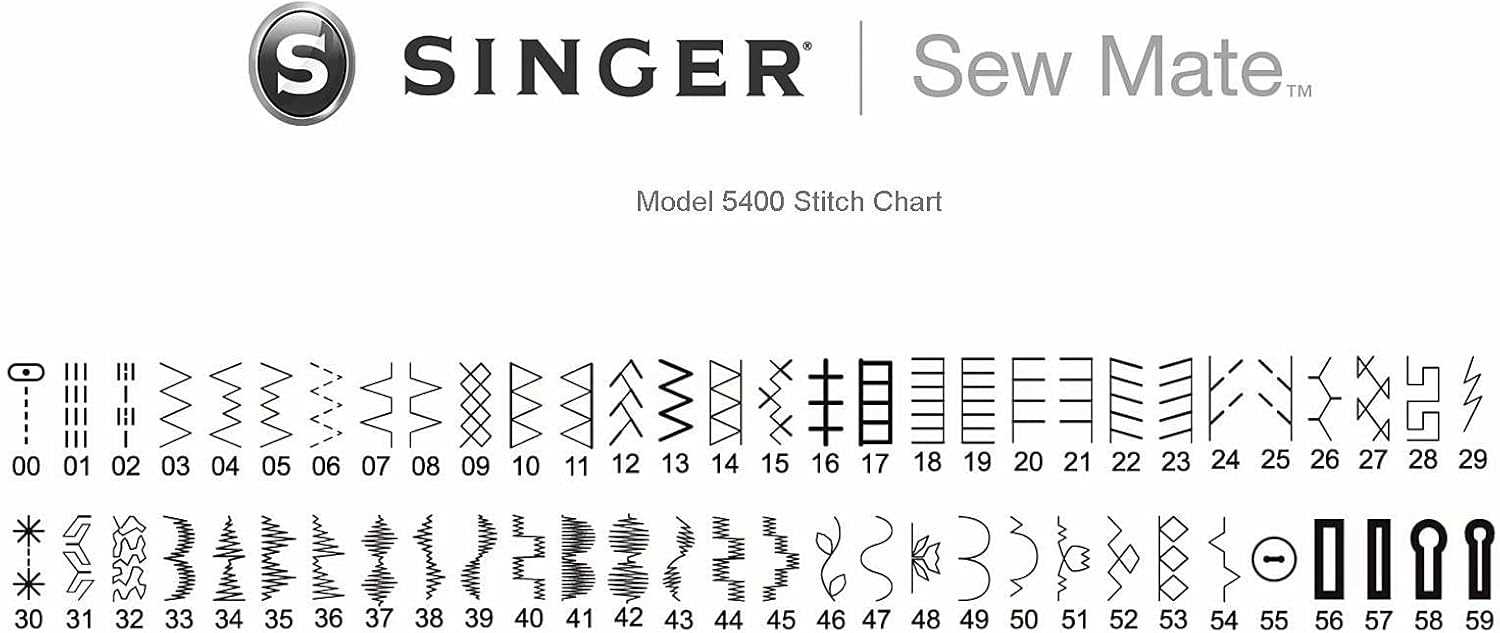

How to Select and Change Stitches

Choosing and altering stitch patterns is a fundamental aspect of operating a modern sewing machine. Understanding how to efficiently navigate and adjust these settings can enhance your projects and ensure that you achieve the desired results for various fabrics and designs.

Selecting a Stitch Pattern

To choose a stitch, first access the stitch selection menu on your machine. This menu typically displays an array of options, each represented by a unique symbol or number. Navigate through these options using the appropriate buttons or dial. Once you have identified the stitch that matches your project’s requirements, confirm your selection by pressing the corresponding button or ensuring the correct number is displayed.

Changing the Stitch Type

After selecting a basic stitch, you may want to adjust its width, length, or tension. Most machines offer dedicated controls for these settings. For stitch length, locate the corresponding dial or button, and adjust it according to the fabric’s thickness or the desired look. Similarly, to alter stitch width, use the relevant controls. Ensuring the correct tension is crucial for avoiding puckering or loose stitches, which can be adjusted with a specific knob or setting menu.

| Function | Control | Purpose |

|---|---|---|

| Select Stitch | Menu Button/Dial | Choose the desired stitch pattern. |

| Adjust Length | Length Dial/Button | Set the stitch length for different fabric types. |

| Adjust Width | Width Dial/Button | Change the width of the stitch for varied effects. |

| Set Tension | Tension Knob/Menu | Ensure the correct tension for a balanced stitch. |

Maintenance Tips for Long-Lasting Performance

To ensure that your sewing machine continues to operate efficiently and reliably, regular upkeep is essential. Proper care and timely maintenance can significantly extend the lifespan of your equipment and prevent common issues from arising. By adhering to a few simple practices, you can maintain optimal functionality and avoid costly repairs.

First and foremost, keeping the machine clean is crucial. Dust and fabric lint can accumulate inside the device, leading to potential malfunctions. Regularly remove the needle plate and clean out any debris using a soft brush or vacuum attachment designed for electronics. Additionally, changing the needle as soon as it shows signs of wear will help maintain smooth operation and prevent damage to the fabric or the machine itself.

Lubrication is another key aspect of maintenance. Consult your equipment’s guidelines for recommended lubricants and apply them to the moving parts as needed. This will help reduce friction and ensure that all components function seamlessly. However, be cautious not to over-lubricate, as excess oil can attract dust and cause more harm than good.

Regularly inspecting and adjusting the tension settings will also contribute to consistent performance. Ensure that both the thread tension and bobbin tension are correctly calibrated to avoid uneven stitching or thread breakage. If you notice any unusual sounds or changes in stitching quality, addressing these issues promptly can prevent more serious problems.

Finally, always follow the manufacturer’s recommendations for service intervals. Professional servicing can address any internal issues that are not visible during routine cleaning. By staying proactive and adhering to these maintenance practices, you will ensure that your sewing machine remains in top condition for years to come.

Troubleshooting Common Sewing Machine Issues

When working with a sewing machine, encountering problems can be frustrating. Understanding common malfunctions and their solutions can help you get back to your projects with minimal disruption. This guide will address frequent issues that users may face, offering practical solutions to keep your machine running smoothly.

Here are some typical problems and their resolutions:

| Problem | Possible Causes | Solutions |

|---|---|---|

| Machine is not stitching | Needle is not inserted correctly, thread tension is incorrect, or bobbin is improperly loaded | Check needle placement and ensure it is securely inserted. Adjust thread tension settings and re-thread the machine. Make sure the bobbin is correctly installed and wound. |

| Fabric is bunching up | Thread tension is too tight, or the feed dogs are not engaged | Loosen the thread tension and ensure that the feed dogs are in the correct position for the fabric type you are using. Clean any lint around the feed dogs if necessary. |

| Needle keeps breaking | Needle is damaged, incorrect needle type, or incorrect threading | Replace with a new needle of the appropriate type and size for your fabric. Check the threading path to ensure proper setup and avoid using a damaged needle. |

| Machine makes a loud noise | Accumulation of dust or lint, or improper lubrication | Clean the machine thoroughly and lubricate as per the manufacturer’s recommendations. Regular maintenance can help prevent unusual noises. |