Effective cutting tools are essential for achieving accurate and efficient results in various woodworking and construction projects. Mastering the use of these tools not only enhances the quality of your work but also ensures safety and productivity. This guide delves into the operational aspects and maintenance of one such cutting instrument, offering practical advice for users of all skill levels.

Understanding the fundamental techniques and proper handling of your cutting equipment is crucial for optimal performance. Whether you’re a seasoned professional or a DIY enthusiast, having a comprehensive overview of your tool’s functions will significantly contribute to the success of your projects. Dive into this guide to discover key insights and tips for using your cutting tool effectively.

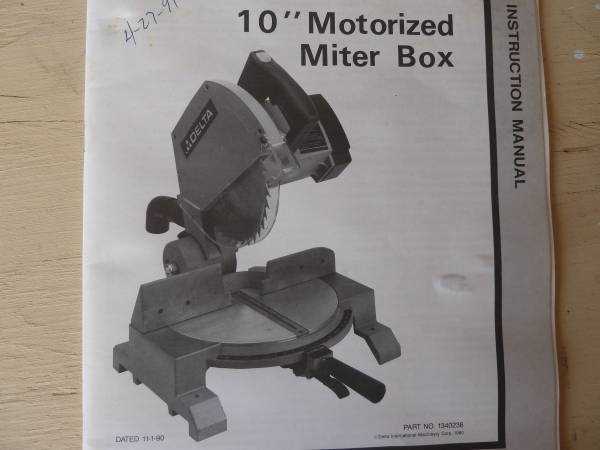

Delta 10 Miter Saw Overview

This section provides a comprehensive look at a powerful cutting tool designed for precision and versatility. Ideal for both professionals and DIY enthusiasts, this tool excels in making accurate crosscuts and angled cuts, enabling users to achieve clean, precise results in their projects.

| Feature | Description | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Blade Size | 10-inch blade designed for various cutting tasks. | ||||||||||

| Cutting Capacity | Accommodates larger materials with ease, enhancing versatility. | ||||||||||

| Adjustability | Offers precise angle adjustments for accurate cuts. |

| Step | Description |

|---|---|

| 1 | Attach the base to the main unit using the provided screws. |

| 2 | Secure the handle and adjust the angle settings as per the guidelines. |

| 3 | Install the blade guard and ensure it operates smoothly. |

| 4 | Check all connections and tighten any loose screws. |

After assembly, double-check all adjustments and perform a test run to confirm proper setup. Ensure that all safety features are in place before use.

Operating Procedures and Safety Tips

Understanding the correct usage and adhering to safety guidelines is crucial when working with power tools. Proper operation ensures efficiency, extends the tool’s lifespan, and, most importantly, maintains user safety. This section covers essential practices to follow for safe and effective use.

Proper Handling Techniques

Before using the tool, ensure that you are familiar with its components and controls. Always check that the tool is properly set up and secured. Wear appropriate personal protective equipment, such as safety glasses and gloves, to prevent injuries. Maintain a stable stance and keep your hands away from the cutting area to avoid accidents.

Safety Precautions

Always inspect the tool for any damage or wear before each use. Ensure that the cutting area is clear of any debris or obstructions. Avoid distractions while operating the tool and do not bypass safety features. Regular maintenance and cleaning of the tool are essential for safe operation.

Maintenance and Care Guidelines

Proper upkeep and maintenance are essential to ensure the longevity and optimal performance of your cutting tool. Regular attention to its care will help maintain precision and functionality, reducing the risk of malfunctions and extending the life of the equipment.

Routine Cleaning: Keep the tool free from dust and debris by regularly cleaning its surface and components. Use a soft brush or compressed air to remove particles that could affect performance.

Inspection and Lubrication: Periodically inspect moving parts for signs of wear or damage. Apply appropriate lubricants to the necessary parts to ensure smooth operation and prevent rusting.

Blade Maintenance: Check the blade for sharpness and replace it when necessary. Ensure it is properly aligned and securely fastened to avoid uneven cuts or potential hazards.

Storage: When not in use, store the tool in a dry, clean environment. Protect it from extreme temperatures and moisture to prevent corrosion and other forms of damage.

Troubleshooting Common Issues

When working with cutting tools, encountering problems is common. Understanding how to address these issues effectively ensures that the tool operates smoothly and safely. This section will explore frequent challenges users face and provide solutions to resolve them.

Tool Not Starting

- Ensure the tool is plugged in securely and the power source is functional.

- Check for a tripped circuit breaker or blown fuse in the power supply.

- Inspect the power switch for any damage or malfunction.

Inconsistent Cutting Performance

- Verify that the blade is sharp and free from debris.

- Ensure the blade is properly aligned and securely attached.

- Examine the material being cut to confirm it is properly supported and not causing interference.

Replacement Parts and Accessories

Ensuring the longevity and optimal performance of your cutting tool involves understanding the necessary components and optional enhancements available. Replacing worn-out or damaged parts and utilizing additional accessories can significantly enhance the tool’s functionality and precision. This section provides an overview of the various components and supplementary items you may need to maintain or upgrade your equipment.

Common replacement parts include blades, bearings, and brushes. Each of these components plays a crucial role in the operation of the tool and should be replaced when signs of wear become apparent. Additionally, accessories such as extension tables, dust collection systems, and laser guides can improve the overall efficiency and accuracy of your tool.

Consulting the manufacturer’s recommendations and using genuine parts will ensure compatibility and reliability. Always verify that any replacement part or accessory meets the specifications required for your particular model to achieve the best results.