Understanding the proper use and features of your high-performance equipment is essential for ensuring both safety and efficiency during various cutting tasks. This guide is designed to help users navigate the setup and operation of their precision tool, providing clear and detailed explanations tailored for both beginners and experienced operators.

The content that follows will walk you through each step necessary to master the use of your tool, from initial assembly to advanced cutting techniques. By following these guidelines, you can maximize the tool’s potential while maintaining optimal safety practices.

Whether you’re performing routine maintenance or tackling a complex project, this guide serves as an invaluable resource. The sections below offer insights into various operational aspects, enabling you to achieve professional-grade results with confidence.

Understanding Basic Operation

The fundamental operation of this equipment revolves around ensuring accuracy and efficiency in various tasks. Mastering the use of the device involves becoming familiar with its primary controls and settings, which will allow you to achieve precise results consistently. Understanding how to handle the equipment properly is key to maximizing its potential and ensuring safe usage.

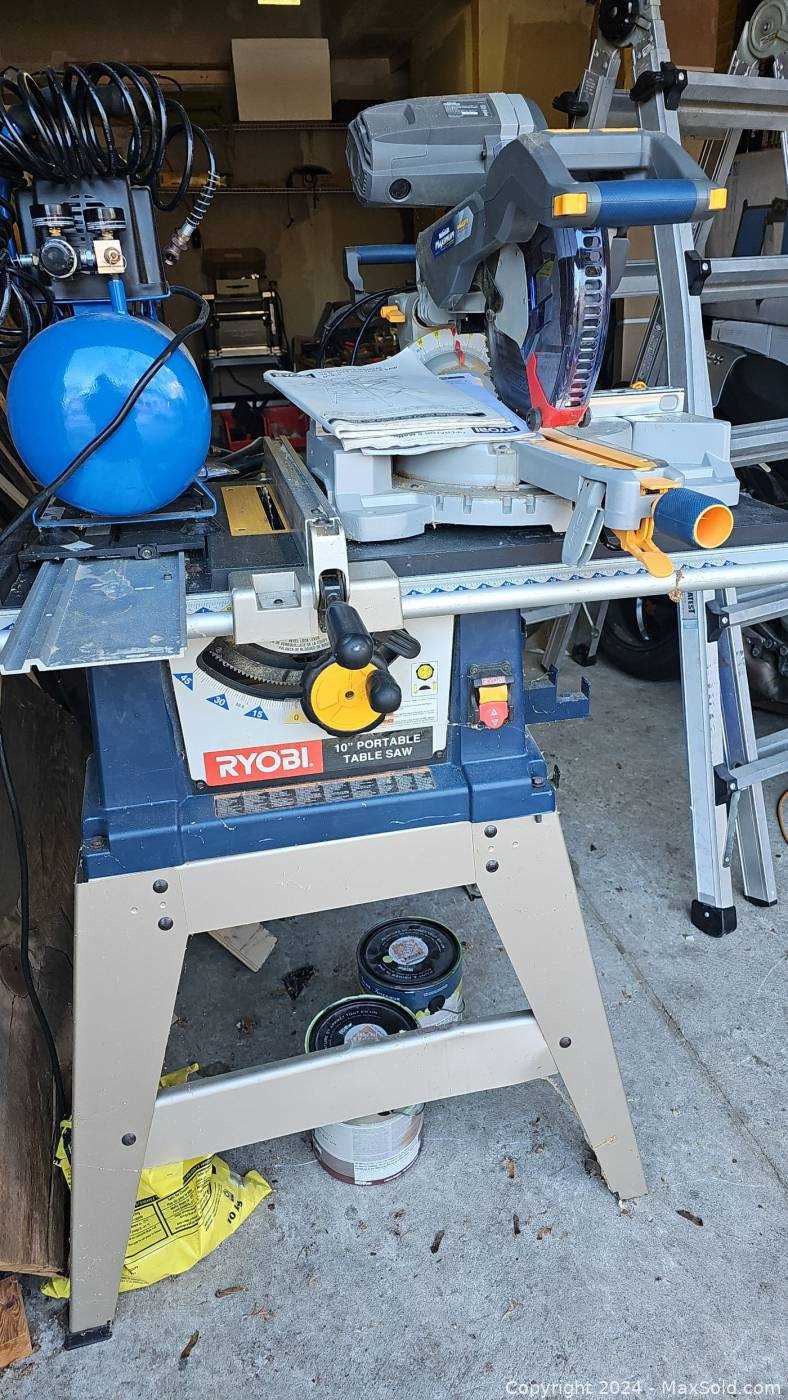

Initial Setup

Before beginning, it’s essential to configure the device correctly. This includes adjusting the work surface, aligning the necessary components, and ensuring that all safety mechanisms are engaged. Proper setup minimizes errors and enhances performance.

Operating Procedures

To utilize the tool effectively, follow the recommended procedures step by step. This typically involves selecting the appropriate settings, positioning the material correctly, and executing the operation with controlled movements. Adhering to these

Safety Precautions and Guidelines

Understanding and following safety protocols is essential when working with any power tool. Proper adherence to these guidelines helps ensure both your protection and the longevity of the equipment.

Personal Protective Equipment (PPE): Always wear the appropriate gear to safeguard yourself from potential hazards. This includes eye protection, hearing protection, and suitable clothing. Failure to wear proper PPE can lead to serious injuries.

Environment Awareness: Before starting, ensure that your workspace is clear of any obstacles. Make sure the area is well-lit and that you have a stable surface to work on. Avoid distractions and stay focused on the task at hand.

Tool Maintenance: Regularly inspect your equipment to confirm it is in proper working order.

Adjusting for Precision Cuts

Achieving accurate cuts is crucial for any project. Fine-tuning your equipment ensures that each cut is consistent, leading to a professional finish. In this section, we’ll explore techniques to enhance cutting accuracy, focusing on alignment, calibration, and the proper use of guides.

Alignment and Calibration

Proper alignment is the foundation of precise cutting. Regularly check the tool’s angles to ensure they are set correctly. Adjust the bevel and angle settings carefully, using a square or protractor to verify accuracy. Calibration of the blade position relative to the guide is also essential for maintaining straight cuts.

Utilizing Guides for Accuracy

Guides play a vital role in achieving consistent results. Always ensure that the fence is parallel to the cutting surface and that the workpiece is firmly secured. Consider using clamps or additional supports to minimize movement during the cutting process.

Maintenance and Cleaning Tips

Proper care and regular upkeep are essential to ensure the longevity and optimal performance of your equipment. This section provides practical advice on how to maintain and clean your tool effectively.

- Regular Inspection: Check all components for signs of wear or damage. Identifying issues early can prevent more significant problems dow

Troubleshooting Common Issues

When dealing with challenges during operation, it’s essential to identify and address common problems that may arise. Understanding potential causes and implementing practical solutions can ensure smooth and efficient performance. Below are some frequent issues and tips on how to resolve them effectively.

Blade Alignment Problems

Misalignment can lead to inaccurate cuts and uneven edges. To correct this, ensure that the cutting mechanism is properly aligned with the work surface. Adjust the necessary components and verify the accuracy before resuming use. Regular maintenance checks can help prevent future misalignment.

Power Supply Interruptions

Intermittent power supply can disrupt the operation and lead to inconsistent performance. First, check the power connections and ensure they are secure. Inspect the power cord for any signs of wear or damage. If

Enhancing Performance with Accessories

Maximizing the efficiency of cutting tools involves integrating a variety of supplementary components designed to improve precision and functionality. These add-ons can significantly enhance the capabilities of your equipment, enabling it to tackle a broader range of tasks with greater ease.

To get the most out of your tool, consider the following accessories:

- Precision Guides: These help ensure accurate and consistent cuts, reducing the margin of error in your projects.

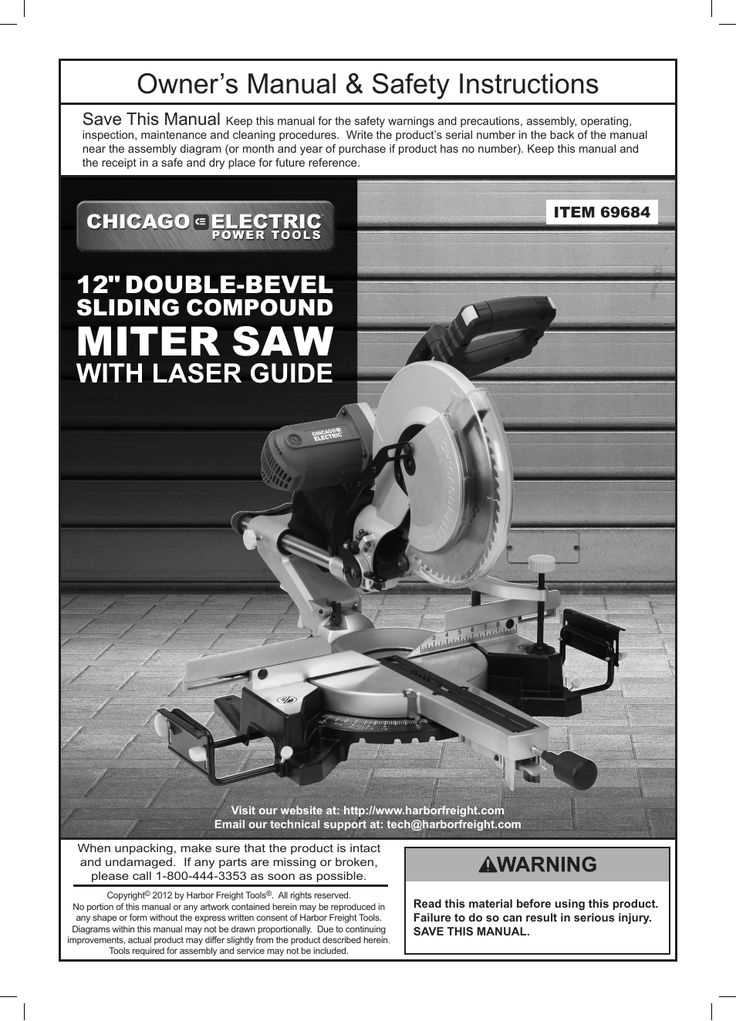

- Laser Guides: Aids in aligning the cut line for greater precision, making it easier to achieve perfect cuts every time.

- Dust Collection Systems: Keeps your workspace clean by efficiently removing sawdust and debris, which also extends the life of your tool.

- Adjustable Stands: Provides stability and support for larger workpieces, improving safety and control during cutting tasks.

- Specialized Blades: Offers enhanced performance for specific materials or cut types, such as finer finishes or faster cutting through dense materials.

Incorporating these accessories not only boosts the performance of your equipment but also enhances overall safety and efficiency. By choosing the right add-ons, you can ensure your tool remains versatile and effective for a wide range of applications.