In today’s rapidly evolving technological landscape, mastering sophisticated control mechanisms is crucial for optimizing operational efficiency. This segment delves into the intricacies of advanced control units designed for modern climate management systems. These devices play a pivotal role in enhancing performance, ensuring energy efficiency, and extending the lifespan of various components within a complex infrastructure.

Our focus is on a particular model renowned for its versatility and precision in regulating environmental systems. This guide provides an in-depth exploration of the functionalities, operational strategies, and setup procedures essential for leveraging the full potential of this advanced controller. Understanding these elements is vital for achieving seamless integration and maximizing the effectiveness of your control systems.

Whether you’re a seasoned professional or a newcomer, this resource is crafted to offer comprehensive insights into the setup and utilization of high-end control solutions. By familiarizing yourself with these instructions, you can enhance your ability to manage and optimize complex systems with greater ease and efficiency.

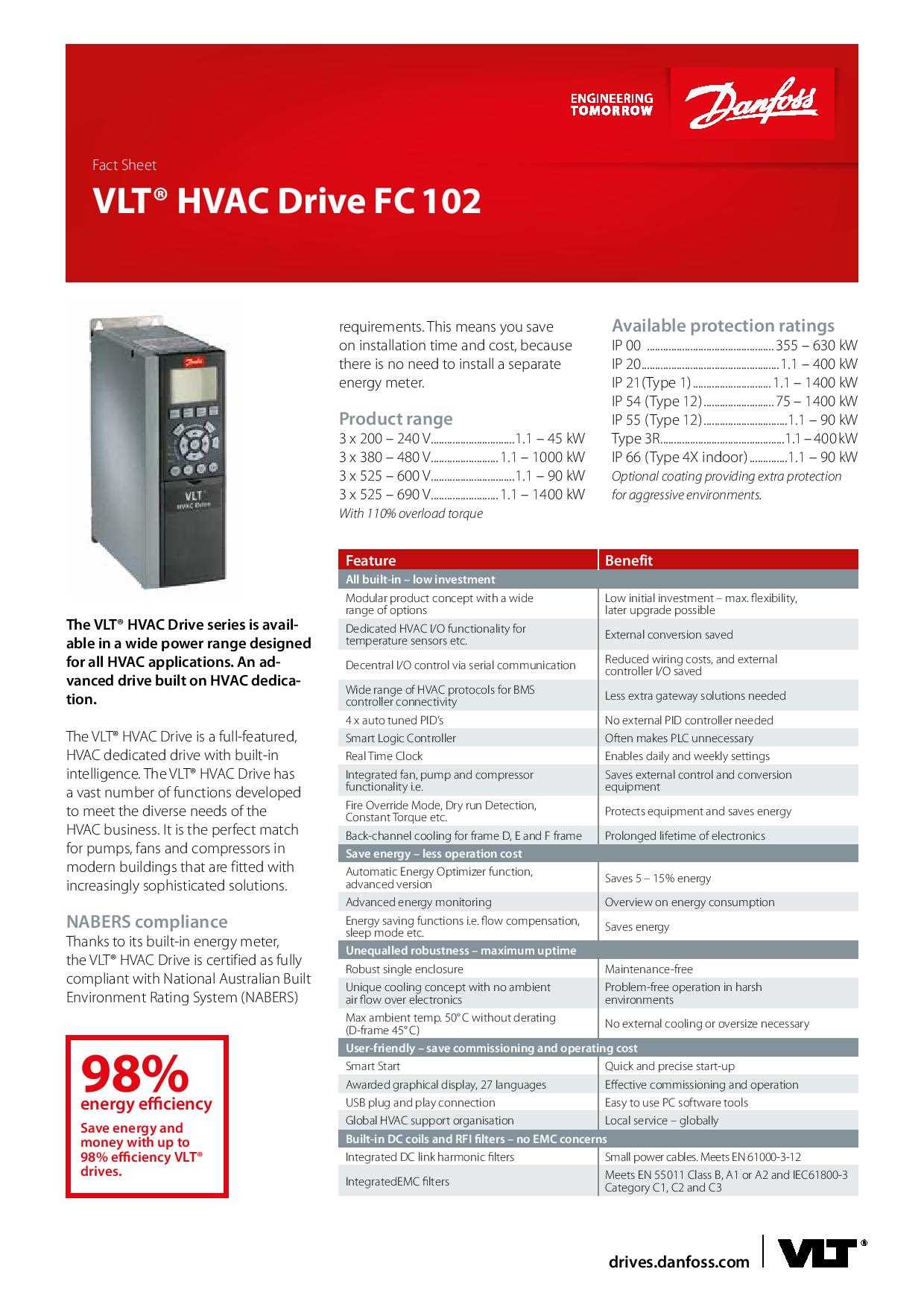

Overview of Danfoss VLT HVAC Drive FC 102

This section provides a comprehensive look at a high-performance control solution designed for managing heating, ventilation, and air conditioning systems. This unit is engineered to enhance operational efficiency and energy savings in various climate control applications. Below, we explore its core features and benefits, giving insight into its functionality and suitability for modern building management systems.

- Advanced Control Features: The unit offers precise regulation of motor speed and torque, ensuring optimal performance and efficiency in managing HVAC systems.

- Energy Efficiency: By utilizing sophisticated algorithms, this controller minimizes energy consumption, reducing operational costs and environmental impact.

- Ease of Integration: Designed to seamlessly integrate with existing building management systems, this device simplifies installation and configuration.

- User-Friendly Interface: The control panel is equipped with a clear and intuitive interface, allowing for straightforward programming and monitoring.

- Robust Design: Constructed to withstand harsh operating conditions, this controller ensures reliable performance and longevity in demanding environments.

Overall, this advanced control unit stands out for its combination of efficiency, ease of use, and durability, making it a valuable addition to any HVAC system.

Key Features and Specifications

This section provides an overview of the essential characteristics and technical details of the advanced control unit designed for efficient energy management in various systems. It outlines the fundamental attributes and operational capabilities that define the performance and versatility of the device.

The unit is equipped with state-of-the-art technology to ensure precise regulation of speed and torque, offering enhanced control over system operations. It supports a wide range of voltage and current specifications, allowing for compatibility with diverse applications. Its advanced digital interface simplifies programming and monitoring, providing real-time feedback and easy adjustments.

Additionally, the unit features robust protection mechanisms against overcurrent, overheating, and electrical faults, ensuring reliable performance under demanding conditions. With its energy-efficient design, it contributes to significant cost savings and improved system sustainability. The compact form factor and modular design further facilitate seamless integration and maintenance.

Installation Guidelines for Optimal Performance

Proper installation is crucial for ensuring that your equipment operates efficiently and reliably. Following best practices during setup can significantly enhance performance and longevity, as well as reduce the risk of operational issues. This guide provides essential steps and recommendations to achieve optimal results from your system.

- Site Selection: Choose an installation location that offers ample ventilation and is free from excessive dust, moisture, and temperature fluctuations. Ensure the site allows for easy access for maintenance and inspection.

- Foundation and Mounting: Install the unit on a stable, level surface to prevent vibrations and ensure proper alignment. Use appropriate mounting hardware and follow the manufacturer’s guidelines for securing the equipment.

- Electrical Connections: Verify that the electrical supply matches the specifications of the unit. Properly connect all power cables and ensure grounding is correctly implemented to avoid electrical hazards.

- Wiring and Cabling: Route wiring and cables neatly and avoid sharp bends or potential sources of damage. Use suitable cable types and ensure all connections are secure and insulated.

- Configuration: Follow the setup procedures outlined in the technical documentation to configure the unit according to your specific requirements. Ensure all settings are correctly adjusted to optimize performance.

- Initial Testing: Conduct thorough testing after installation to confirm that the system operates as intended. Check all functions, calibrate as necessary, and monitor for any irregularities.

- Regular Maintenance: Establish a routine maintenance schedule to inspect and service the equipment. Regular checks can help identify potential issues early and ensure continued efficiency.

Understanding the Control Interface

Grasping the control interface is crucial for optimizing the performance of your equipment. This section delves into how users interact with the system through various input methods and settings. By comprehending these controls, operators can efficiently manage and fine-tune the equipment to meet specific operational requirements.

The control interface generally consists of several key components:

- Display Screen: Provides real-time information and status updates about the system’s performance. It often includes diagnostics, performance metrics, and operational settings.

- Buttons and Switches: Used to navigate menus, adjust parameters, and execute commands. Each button typically has a designated function which can be customized based on user preferences.

- Knobs and Dials: Allow for precise adjustments of settings such as speed, temperature, or pressure. They offer fine-tuned control over the system’s operation.

- Indicator Lights: Show the current status or alert the user to any operational issues. They provide quick visual feedback about the system’s condition.

To effectively use the control interface, follow these general steps:

- Familiarize Yourself: Read through the documentation to understand the layout and functions of each component on the interface.

- Set Up Initial Parameters: Configure basic settings according to your operational needs. This may involve adjusting speed, temperature, or other relevant parameters.

- Monitor Performance: Use the display screen to keep track of system performance and make adjustments as needed based on real-time data.

- Respond to Alerts: Pay attention to indicator lights and error messages. Address any issues promptly to maintain optimal performance.

Mastering the control interface enables users to maximize efficiency and maintain the reliability of their systems. Understanding how to interact with and adjust settings is essential for effective management and operation.

Troubleshooting Common Issues

When operating and maintaining modern control systems for temperature and airflow regulation, users may encounter various challenges. Addressing these common problems effectively requires a systematic approach to identify and rectify the underlying causes. This section provides guidance on resolving frequent issues that may arise during the use of such systems.

One typical issue is the system’s failure to start. This can often be attributed to electrical problems such as loose connections or tripped circuit breakers. Ensuring that all power sources are securely connected and that breakers are in the correct position can resolve this problem. Additionally, verify that all system parameters are correctly set according to operational requirements.

Another common problem is unusual noise during operation. This may result from mechanical issues, such as worn bearings or misaligned components. Regular inspection and maintenance of moving parts can help prevent these issues. Lubrication and proper alignment of parts often mitigate noise-related problems.

If the system displays erratic performance or fluctuating outputs, it may be due to calibration errors or sensor malfunctions. Checking and recalibrating sensors, as well as ensuring that all settings are correctly configured, can restore stable performance. Regular diagnostics can help identify and address these types of issues promptly.

By following these troubleshooting steps, users can effectively manage and resolve common operational problems, ensuring the reliable performance of their control systems.

Maintenance Tips for Longevity

Ensuring the long-term performance and reliability of your equipment involves adhering to regular upkeep practices. Proper maintenance helps prevent unexpected failures and extends the operational life of your system. Following a consistent routine for inspection and servicing is crucial for maintaining efficiency and avoiding costly repairs.

Begin by regularly checking all electrical connections and components for signs of wear or damage. Secure and clean connections as necessary to avoid potential issues. Inspect the cooling and ventilation systems to ensure they are free from obstructions and functioning optimally. Replacing air filters and other consumables at recommended intervals prevents clogging and maintains proper airflow.

Monitor system performance through periodic diagnostics to identify any anomalies early. Address any unusual noises or vibrations promptly, as these may indicate underlying problems. Keeping the equipment clean from dust and debris is essential, as accumulation can impair performance and lead to overheating.

Finally, adhere to the manufacturer’s guidelines for lubrication and calibration. Properly lubricating moving parts reduces friction and wear, while regular calibration ensures the equipment operates within specified parameters. By following these maintenance practices, you can significantly enhance the lifespan and efficiency of your system.

Upgrading and Integration with Existing Systems

When modernizing your control systems and incorporating advanced technology, it is crucial to ensure seamless compatibility with your current infrastructure. Upgrading to newer, more efficient equipment involves a series of strategic steps to maintain or enhance performance while integrating with pre-existing systems.

First, assess the compatibility of new components with your current setup. This involves checking communication protocols, electrical requirements, and physical dimensions to ensure that the new equipment can be properly integrated without major modifications to the existing system.

Next, conduct a thorough analysis of the existing system’s operational parameters and limitations. Understanding these factors will help in configuring the new system to work efficiently and effectively, minimizing disruptions during the transition.

Moreover, it is essential to plan for a phased implementation if needed. This approach allows for gradual integration, reducing the risk of system downtime and facilitating easier troubleshooting and adjustments.

Lastly, provide comprehensive training for personnel on the updated system. Familiarity with new features and functionalities will ensure that the system operates optimally and that any potential issues are addressed swiftly.