Efficient operation and maintenance of HVAC systems require precise tools capable of delivering accurate measurements. Understanding how to fully utilize these tools is essential for both professionals and enthusiasts in the field. This guide offers a thorough exploration of one of the most reliable instruments available, providing insights into its features and how it can enhance your work.

The sections ahead will delve into the key functions and settings of the device, highlighting the steps necessary for proper usage. With clear explanations and practical tips, this resource is designed to help you make the most of your equipment, ensuring your tasks are completed with precision and confidence.

Whether you’re fine-tuning a system or conducting routine checks, mastering this tool will significantly improve your efficiency and accuracy. Continue reading to unlock the full potential of your HVAC measurement equipment.

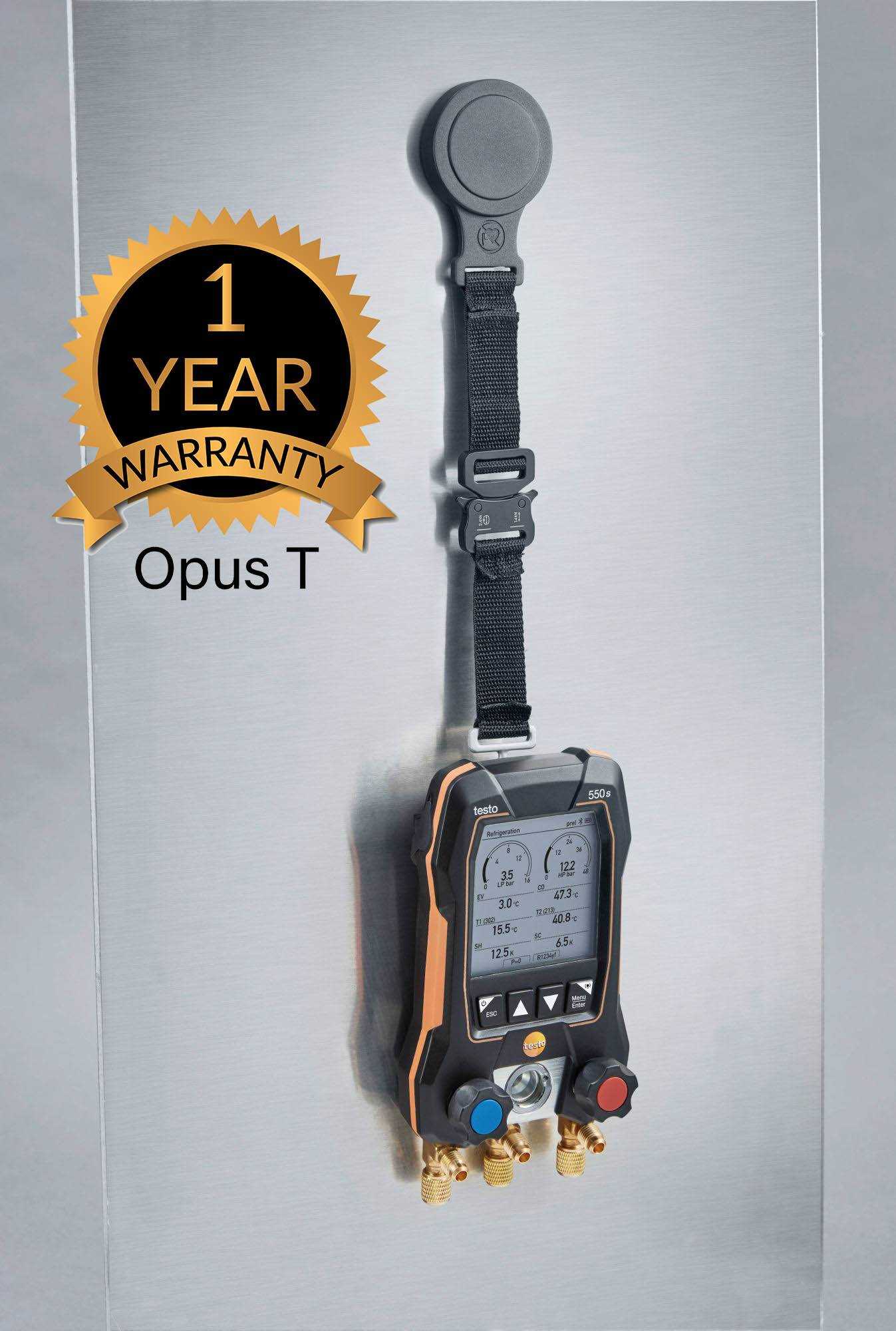

Testo 550 Overview and Key Features

The device under review is a high-performance digital manifold designed to meet the needs of HVAC technicians and refrigeration specialists. Engineered for precise measurement and analysis, this tool integrates various advanced features that enhance workflow efficiency and data accuracy. It stands out in the market due to its robust construction and user-friendly interface, making it an essential companion for professionals in the field.

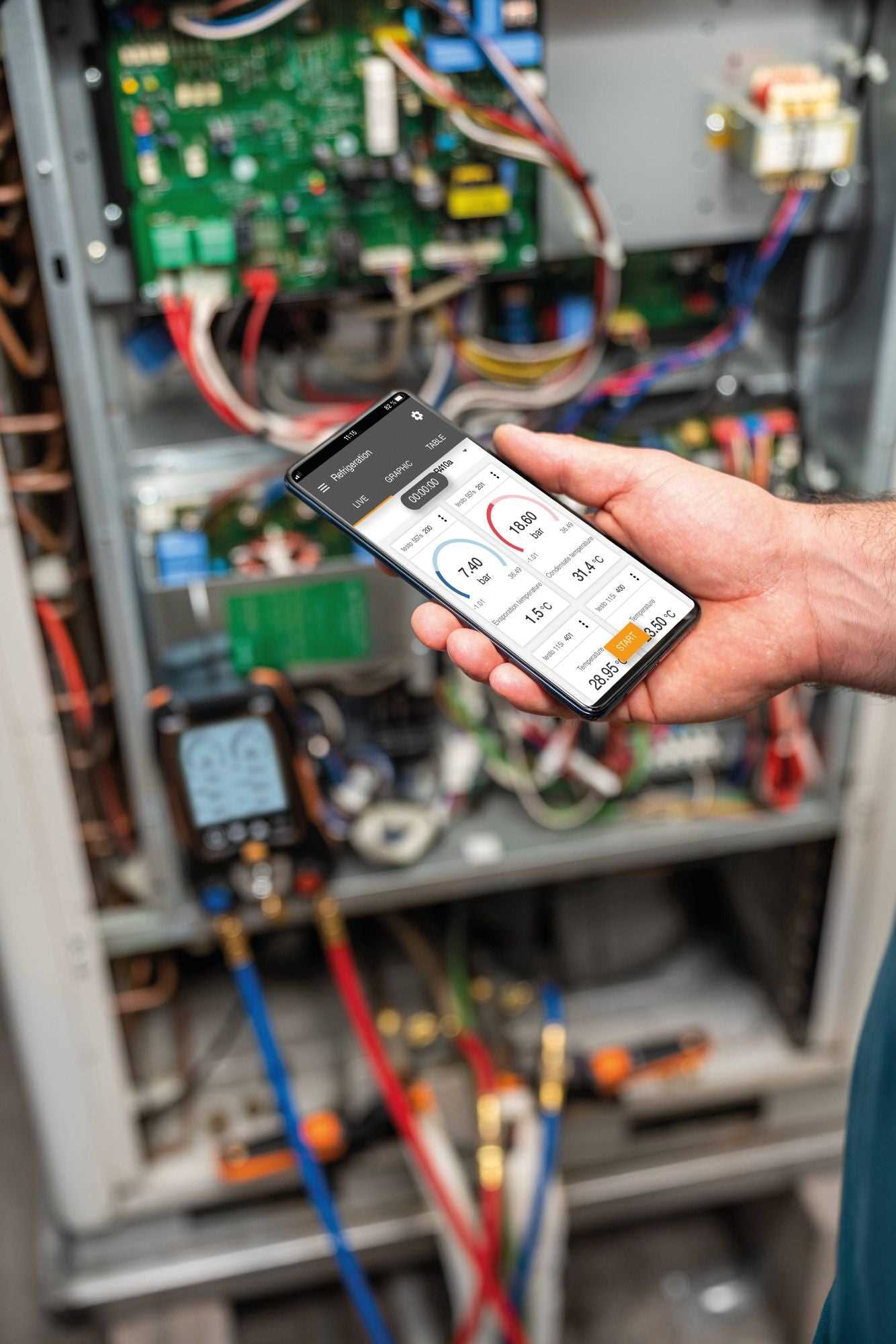

Key Features: This tool is equipped with dual pressure sensors that provide accurate readings across a wide range. Its intuitive display ensures that critical information is presented clearly, even in challenging environments. Moreover, the integration of wireless connectivity allows seamless data transfer to external devices, enabling real-time monitoring and analysis. Durability is a key aspect, with the device being built to withstand harsh conditions, ensuring long-term reliability. An automatic calculation feature simplifies complex diagnostics, saving time and reducing the likelihood of errors.

Versatility is another notable characteristic, with the ability to handle various refrigerants, making it adaptable to different applications. Additionally, the compact design enhances portability, while the ergonomic layout ensures comfortable use during extended periods. The combination of these features makes this device a crucial tool for those seeking precision and efficiency in their work.

Understanding the Display and Controls

The user interface plays a crucial role in efficiently operating the device. Familiarity with the layout and functions ensures accurate readings and smoother operation. This section provides an overview of the visual indicators and control elements, offering guidance on how to navigate the various features.

Display Layout

The screen presents key information at a glance, making it easy to monitor and analyze data in real-time. Different sections of the display are dedicated to specific parameters, ensuring that each piece of information is clear and accessible. Symbols and numbers are strategically placed to enhance readability.

Control Functions

The control buttons are designed for intuitive operation, allowing the user to swiftly interact with the device. Each button has a distinct function, from adjusting settings to switching modes. Understanding the purpose of each control enhances the efficiency and accuracy of the device’s operation.

Tip: Regularly review the control functions to maintain proficiency, ensuring that all features are utilized to their full potential.

Connecting the Manifold to HVAC Systems

Accurate connection of the manifold to HVAC systems is crucial for effective diagnosis and maintenance of the equipment. Properly connecting the manifold ensures reliable measurements and helps to maintain system efficiency and safety.

Preparation Steps

Before attaching the manifold, ensure that the HVAC system is turned off and the manifold is properly calibrated. Double-check that all necessary tools and accessories are ready for use.

- Ensure that the manifold is free of contaminants and leaks.

- Inspect hoses for any signs of wear or damage.

- Verify that the service ports on the HVAC unit are accessible.

Connecting the Hoses

Once everything is prepared, begin by connecting the hoses to the appropriate service ports on the HVAC system. This process allows the manifold to accurately measure the pressure and temperature within the system.

- Identify the low-pressure and high-pressure service ports on the HVAC unit.

- Attach the blue hose to the low-pressure port.

- Connect the red hose to the high-pressure port.

- If required, attach the yellow hose to the vacuum pump or refrigerant cylinder.

After the hoses are securely connected, you can proceed with the necessary diagnostic or maintenance procedures, ensuring that all readings are closely monitored for accuracy.

Step-by-Step Guide to Calibration

Proper calibration is essential for ensuring accuracy and reliability in measurement tools. This section provides a detailed process to guide you through calibrating your device, enhancing its precision and performance. Follow these steps carefully to maintain optimal functionality.

- Ensure the device is powered off and the battery is fully charged.

- Connect the tool to a reliable pressure source using the appropriate adapters.

- Turn on the device and allow it to stabilize for a few minutes.

- Access the calibration mode through the settings menu.

- Select the parameter that needs calibration (e.g., pressure, temperature).

- Apply the reference standard for the chosen parameter.

- Adjust the readings on the device to match the reference standard.

- Confirm the calibration and exit the calibration mode.

- Power off the device and disconnect it from the pressure source.

- Test the device with a known standard to verify the accuracy of the calibration.

By following these steps, you can ensure that your equipment delivers precise and consistent results, minimizing errors in your measurements.

Maintenance Tips for Prolonged Use

Regular upkeep is essential to ensure the longevity and optimal performance of your equipment. Adhering to proper maintenance practices not only extends the lifespan of your tool but also enhances its accuracy and reliability in various applications.

- Regular Cleaning: Keep the device free from dust and debris. Use a soft, dry cloth to wipe down surfaces. For stubborn dirt, slightly dampen the cloth with water, avoiding harsh chemicals.

- Inspect Seals and Connections: Periodically check all seals and connections for wear and tear. Replace any damaged components immediately to prevent leaks or inaccuracies.

- Battery Care: Monitor battery levels regularly. Replace batteries when necessary, and store the device with batteries removed if it will not be used for an extended period.

- Proper Storage: Store the equipment in a dry, cool place. Avoid exposure to extreme temperatures or direct sunlight, which could damage sensitive components.

- Software Updates: Ensure that any software associated with the device is kept up to date. Updates often include important performance improvements and bug fixes.

- Calibration Checks: Regularly verify the calibration of the device to maintain precision. Schedule professional calibration if needed.

By following these maintenance guidelines, you can ensure your tool remains in excellent condition, delivering consistent and reliable results throughout its lifespan.

Troubleshooting Common Issues with Testo 550

When working with diagnostic tools, encountering issues is not uncommon. Addressing these challenges promptly and effectively ensures the equipment performs optimally. This section will guide you through resolving frequent problems, helping you maintain accuracy and efficiency in your measurements.

Device Fails to Power On

If the device does not power up, consider checking the following:

- Battery Condition: Ensure the batteries are properly inserted and fully charged. Replace them if necessary.

- Connections: Verify that all connectors are securely attached and free from damage.

Inaccurate Readings

For issues with inaccurate readings, follow these steps:

- Calibration: Check if the device needs recalibration. Refer to the calibration procedure in the guide to ensure it is correctly adjusted.

- Sensors: Inspect the sensors for any obstructions or damage. Clean or replace them if needed.

By systematically addressing these common issues, you can restore your device to proper functioning and ensure reliable performance in your diagnostic tasks.